SARTORIUS Werkzeuge

Products

H. Sartorius Nachf. GmbH & Co. KG

End millers

PALBIT Schaftfräser/Einschraubfräser/Eckfräser 90° LINEPRO 20190

ATORN Keramikfräser

|

Others cutting tool

ATORN Kreissegmentfräser

|

End miller

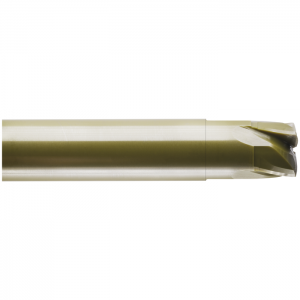

ATORN® HPC Power-Hochleistungsprogramm

|

End miller

H. Sartorius Nachf. GmbH & Co. KG

End millers

Strong against everything!

With the new ATORN® HPC POWER high performance program has been significantly increased the performance of the low-vibration Premiumwerkzeuge. It is an innovative HPC geometry cutter program that is designed for the high economic universal machining of steel, stainless steel, non-ferrous metals, iron and special alloys.

In processing, substantially higher metal removal rate are the result of different swirl climbs in connection with newly developed, stable face and coat cut. Even with extreme cutting data convince the tools by a particularly high smoothness, high process reliability and low machine load.

Immersion and so-called Rampingprozesse are favored by the optimized Stirngeometrien. The new solid carbide with an innovative PVD-high-performance coating also contributes to improved lifetime and more secure chip evacuation.

Advantages:

• Boost productivity - roughing and finishing with the same tool

• very good surface finish even at high feed rates

• long life through optimised cutting edge geometries and high performance coatings

• Processing types such as immersion/drilling or ramping possible

• low machine exposure to very smooth running, long service life

• comprehensive application possibilities and economic machining of difficult materials

• suitable for all modern milling strategies such as E.g. Trochoidal milling

This description was translated from German to English by "Bing Translator".

PALBIT Schaftfräser 90° LINEPRO 20090 & PALBIT Einschraubfräser 90° LINEPRO 20090

|

End miller

H. Sartorius Nachf. GmbH & Co. KG

End millers

SARA®MILL High-Performance

|

End miller

H. Sartorius Nachf. GmbH & Co. KG

End millers

Sara® MILL high-performance S and M is the complete range of corner and Nutfräsern for universal application possibilities: roughing and finishing of steel, aluminum, graphite, plastics and hardened materials and also for the Stainless steel machining. Ideally suited to plan -, slot, circumferential, and Pocket milling as well as to the inclined and circular plunge.

Thread milling cutters, end mills with Weldonfläche and shaft-mounted cutter designs. The screw-in tools are appropriate in connection with an extension of hard metal finishing at great depths. Extremely precisely manufactured carrier ensure excellent cutting results. Through the optimum coolant supply no chips on the rake face stick to the cutting edge. Process-safe milling is possible in difficult materials.

Small and large in performance, the tools are a very light cut characterized by. The tools are multifunctional with extensive reversible cutting plates range for all applications. With specially developed indexable tools even as high feed cutter for the HighFeed hard machining of all materials are suitable up to 60 + 2 HRC. The custom chip surface geometry of this cutting materials guarantees extremely long life at high running smoothness. For each type of processing offers the SARA® program MILL high-performance S and M the right tool and turning plate combination.

1 face milling cutters

2. circular redeem

3. cant redeem

4. milling cutters of scope of

5. slot milling

This description was translated from German to English by "Bing Translator".