SCHUNK - Gripping and Clamping

Products

Magnetic clamping plates

MAGNOS KEH plus

|

Control unit

SCHUNK SE & Co. KG

Magnetic clamping plates

Description

Modular control units with holding force regulation for magnetizing or demagnetizing of up to eight magnetic chucks.

Advantages – Your benefits

Expandable modular system

Depending on the control unit, up to eight magnetic chucks can be controlled

Various standard versions depending on the case of application

One control unit for all square pole plates with and without status display from SCHUNK

16-step holding force regulation

Allows clamping of thin workpieces and simplifies the alignment of heavier workpieces

Modularly constructed handheld remote control

Allows each magnetic chuck as well as its holding force regulation to be individually controlled

Display of the clamping status via LED

Increasing the safety by knowing whether the workpiece is clamped or released

Display of error codes via LCD display

In the case of malfunctions, the error cause can be found more quickly

Large selection of accessories

The control unit or the magnetic chucks can be quickly and easily adapted to new clamping tasks

Options and special information

Increased user comfort

The modularly designed SCHUNK MAGNOS KEH plus is suitable for all square pole plates from SCHUNK. Three basic versions for the control of one, two, four or eight magnetic chucks and a wide range of different cable and handheld remote controls are sufficient to cover all requirements.

Concerning the selection of a suitable connecting cable, both small magnetic clamping plates with 4-PIN connectors as well as large magnetic chucks with 7-PIN connectors can be actuated. Equipped with connectors, all cables can be quickly and easily exchanged if necessary.

It is also possible to assign vacant slots at any time with additional magnetic chucks. A 16-step holding force regulation process facilitates the alignment of the workpieces and allows for the clamping of thin components.

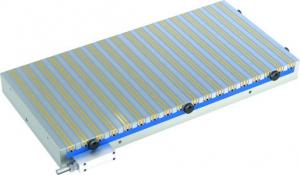

MAGNOS MFRS

|

Magnetic clamping plate

SCHUNK SE & Co. KG

Magnetic clamping plates

Description

Magnetic chucks with extremely high holding forces for milling applications as an ideal clamping solution for powerful metal cutting processes with simultaneous 5-sided workpiece machining in a single set-up.

Field of application

3-axis standard machining center

4-axis vertical machining center

4-axis horizontal machining center

5-axis machining center

Advantages – Your benefits

5-sided workpiece machining in one set-up

Higher accuracy by setting up once and at best accessibility of the machine spindle

Even permanent magnetic clamping force over the entire workpiece

Low deformation and vibration clamping of the workpieces

Low vibration clamping

Improved surface finishes and significantly increased precision.

Deformation-free clamping

No deformation and inner forces in workpiece due to clamping forces

Patented status display

Secure clamping and maximum process reliability

Control unit compatible with machine control system

Can also be used in automated applications

Mono-block design

Compact and robust design with high rigidity

The modular principle

Depending on the application or type of machine, the magnetic can be combined or extended in accordance with the modular design principle

Clamping within a few seconds

Shortest possible set-up times and a resulting increase in productivity

Unique energy supply for MAG/DEMAG process

Energy-efficient and secure clamping of the workpieces

Large selection of accessories

Optimal adaptation possibilities in the respective clamping task

Options and special information

Three square pole sizes for highly individual workpiece clamping

The magnetic chucks are each available in three different square pole dimensions. This offers the possibility of individually adjusting the magnetic chuck to its specific clamping task within a larger range of clamping tasks. The decisive factors are the thickness, weight, surface, geometry, and dimensions of the workpiece being machined.

Magnetic chuck type MFRS-A1

MFRS-A1 magnetic chucks with a high compact performance of acting magnetic force are generally sufficient for 80% of all applications.

Magnetic chuck type MFRS-A2

MFRS-A2 plates have an even higher density of magnetic field penetrating into the workpiece. These are used primarily for workpieces with very uneven surfaces (die-cast and forged parts) and thus a larger air gap, as more magnetic field lines stay in contact with the workpiece.

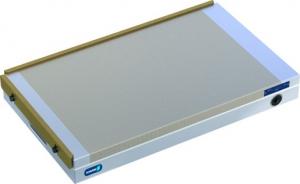

MAGNOS MSC-PM15

|

Magnetic clamping plate

SCHUNK SE & Co. KG

Magnetic clamping plates

Description

Manual permanent magnetic chucks with parallel pole pitch for clamping of small workpieces and thin parts for precision grinding work on grinding machines.

Field of application

Surface grinding machines

Jig milling machines

Profile grinding machines

Advantages – Your benefits

Even permanent magnetic clamping force over the entire workpiece

Low deformation and vibration clamping of the workpieces

Low vibration clamping

Improved surface finishes and significantly increased precision.

Deformation-free clamping

No deformation and inner forces in workpiece due to clamping forces

Mono-block design

Compact and robust design with high rigidity

Clamping within a few seconds

Shortest possible set-up times and a resulting increase in productivity

Low magnetic field height

Prevents a magnetization of the machining tools

Options and special information

The manual MAGNOS MSC-PM15 magnetic chucks are actuated via a lateral hexagon socket connection. The magnetic clamping force can be continuously adjusted. The low magnetic field height prevents magnetization in the machining tools, allowing very thin and small parts to be processed.

MAGNOS MSC-PM35

|

Magnetic clamping plate

SCHUNK SE & Co. KG

Magnetic clamping plates

Description

Manual magnetic chucks with radial pole pitch for machining rings and disks on cylindrical grinding machines.

Field of application

Radial pole Technology

Advantages – Your benefits

Even permanent magnetic clamping force over the entire workpiece

Low deformation and vibration clamping of the workpieces

Low vibration clamping

Improved surface finishes and significantly increased precision.

Deformation-free clamping

No deformation and inner forces in workpiece due to clamping forces

Mono-block design

Compact and robust design with high rigidity

Clamping within a few seconds

Shortest possible set-up times and a resulting increase in productivity

Low magnetic field height

Prevents a magnetization of the machining tools

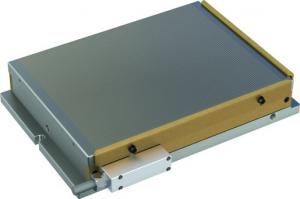

MAGNOS MSC-PM60D

|

Magnetic clamping plate

SCHUNK SE & Co. KG

Magnetic clamping plates

Description

Electro-permanent magnetic chucks with larger parallel pole pitch for clamping of medium-sized and large workpieces on grinding machines.

Field of application

Surface grinding machines

Jig milling machines

Profile grinding machines

Advantages – Your benefits

Even permanent magnetic clamping force over the entire workpiece

Low deformation and vibration clamping of the workpieces

Low vibration clamping

Improved surface finishes and significantly increased precision.

Deformation-free clamping

No deformation and inner forces in workpiece due to clamping forces

Mono-block design

Compact and robust design with high rigidity

Clamping within a few seconds

Shortest possible set-up times and a resulting increase in productivity

Low magnetic field height

Prevents a magnetization of the machining tools

Options and special information

MAGNOS MSC-PM 60 magnetic chucks are connected to the control unit via a lateral connection plug. Due to their large pole pitch, large workpieces can be securely clamped without the magnetic chucks becoming significantly hot.

MAGNOS MSC-PM62F

|

Magnetic clamping plate

SCHUNK SE & Co. KG

Magnetic clamping plates

Description

Electro-permanent magnetic chucks with fine parallel pole pitch for clamping of small workpieces and thin parts for precision grinding works on grinding machines.

Field of application

Surface grinding machines

Jig milling machines

Profile grinding machines

Advantages – Your benefits

Even permanent magnetic clamping force over the entire workpiece

Low deformation and vibration clamping of the workpieces

Low vibration clamping

Improved surface finishes and significantly increased precision.

Deformation-free clamping

No deformation and inner forces in workpiece due to clamping forces

Mono-block design

Compact and robust design with high rigidity

Clamping within a few seconds

Shortest possible set-up times and a resulting increase in productivity

Low magnetic field height

Prevents a magnetization of the machining tools

Options and special information

MAGNOS MSC-PM 62 magnetic chucks are connected to the control unit via a lateral connection plug. The low magnetic field height prevents magnetization in the machining tools, allowing very thin and small parts to be processed.