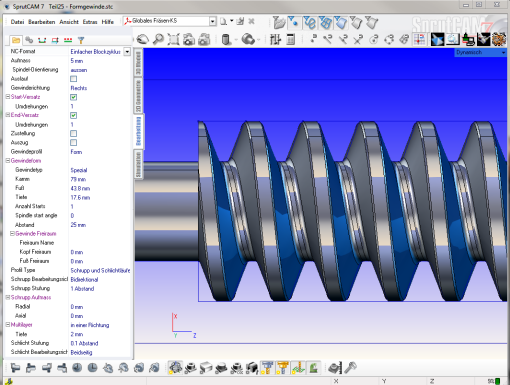

1. Added new operation ‘Lathe contouring’. For full details see below and in the video on our FTP or on YouTube also.

2. In the new operation 'Lathe contouring' changed the toolpath calculation method with tool radius compensation. Now he can achieve more robust and reliable results by reducing the number of transformations to calculate the toolpath.

3. Added support for single-pass threading cycle ISO G92. It is implemented inside the new operation, ‘Lathe contouring’.

4. In all milling operations, added ability to specify a safe distance as a percentage of the machining step. This avoids error "collision with the workpiece at an rapid movement"

5. Fixed bug setting safe coordinates for operations: ‘Hole machining 5D’ and ‘5D contouring’. (Previously, was set to zero the machine, rather than from zero parts).

6. In the window for feedrate setting for turning and milling operations, added a field to specify a range of spindle. This value is displayed in the Spindl command, that allows to develop postprocessor for older machines with mechanical switching speed spindle.

7. During milling operations, using the tool radius compensation has changed the way the inclusion of moves on / off of compensation. Now, if the properties of the operation included the compensation, then moves on / off switch is automatically activated. This avoids incorrect results when the compensation is enabled, but do not have a preparatory movement start. At the same time remained the flexibility to switch on and off switch moves the compensation in each case independently. In all milling operations, added the possibility to set – size of approach/retraction as a percentage of the diameter of the tool. This reduces the time to configure the operations and get the correct results virtually without changing the default settings.

8. The value of overhang of the tool is passed to the postprocessor in LoadTL command.

9. The ability to use smart snap in interactive indication of the components of the job assignment of the Wire EDM operation

10. In SprutCAM Toolslist a dialogue Added option to export information in a file STCX-file. Also exported drawings.

links: http://www.youtube.com/results?search_quer...rutcam&aq=f