Of all businesses, contract machining companies know what they want: Cincinnati-based firm Metalex Manufacturing Inc. already owns three Starrag machine tools, but after extensive benchmarking, the key customer has chosen to invest in a Droop+Rein T portal machining centre from Starrag – its largest investment to date in every respect.

The contract machining company, a specialist in producing sophisticated and high-quality workpieces, was looking for a machine that was capable of machining a wide variety of materials with flexibility, efficiency and precision – all in a single clamping operation. This was where Starrag‘s claim came into play once again. In keeping with the proven philosophy of Engineering precisely what you value, Metalex and a team from Starrag turned their attention to the entire Starrag portfolio.

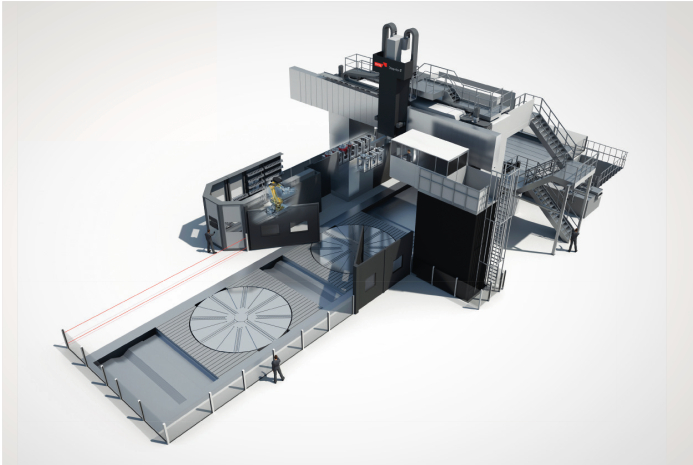

The company ultimately decided on the Droop+Rein T series from the Bielefeld site – a powerful milling/ turning centre offering an outstanding level of accuracy thanks to its perfectly rigid design and hydrostatic guide concept. Just one look at the extraordinary dimensions (table length: 18,000 mm; horizontal pass: 9,000 mm; vertical pass: 7,000 mm) and the huge working area of X:19,000 mm; Y: 9,000 mm; Z: 3,000 mm proves it: We are looking at XXL at its finest. The huge amount of space offered by this new model means that processing large workpieces in a single clamping operation is easy. There is also an option for highly flexible five-axis processing, thanks to the integrated C-axis with stepless rotation and the universal fork-type milling head, featuring a B-axis that swivels ± 95°. The sixth-axis (W) – a 5,500 mm continuously movable crossbeam – complemented the universal approach that the contract machining company required.

The processing centre uses a 100-kW main spindle with a maximum torque of 7,500 Nm, transmitted via vertical and horizontal milling heads; two fork-type milling heads designed for five-axis operation as well as a slim outboard bearing for drilling through.

If entirely new orders come in, there is an option to use additional heads for milling, turning, grinding and turning out. The versatile robot magazine, which has space for up to 400 tools, supplies the milling and turning heads with three different tool systems. Integration into Metalex‘s production and tool management systems is undertaken by the Integrated Production System (IPS), Starrag‘s building block for Industrie 4.0 solutions.

The special table construction with two large tables (6,000 x 8,000 mm) ensures very efficient machining. This construction means that one table can be used under the spindle while the other is loaded and unloaded outside the work area. Extra-long workpieces are machined in coupled tandem operation, for which tables are extended to 18,000 mm. Each table also features an integrated rotary table from the Dörries series (diameter: 6,000 mm). Thanks to the two 111-kW main drives, the turning of components weighing up to 200 tonnes is also possible. The rotary table can also be used as a C-axis for precise positioning when milling and drilling.

All in all, Starrag‘s solution was exactly what Kevin Kummerle was looking for. The CEO of Metalex values healthy growth and continuous development. The new Droop+Rein T portal machining centre plays an important part in this, offering Metalex and its customers impressive long-term benefits in terms of quality, technology, costs and service.

Switzerland

Switzerland