Starrag Group

Products

Horizontal machining centres

Bumotec S1000 C

|

Horizontal machining centre

Starrag Vuadens SA

Horizontal machining centres

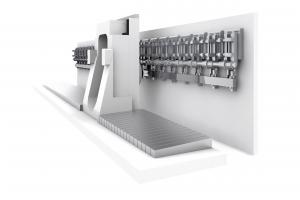

The Bumotec S1000 C horizontal transfer machine was designed to manufacture prismatic parts from round or profiled bar stock. Small and complex components can be efficiently machined in medium to large batch sizes.

The machine is configured with seven 4-axis machining stations, each equipped with 4 machining spindles (2 horizontal and 2 vertical). The eight station comprises a 4-axis cut off station with a single spindle. An optional ninth station allows the component to be reclamped to allow the sixth side of the component to be machined with an additional 3-axis, 3 spindle machining unit. The machine is equipped with an automatic bar feed and quick change tool clamping system for optimum production rates.

ECOLINER

|

High speed machining centre

Starrag Technology GmbH

Horizontal machining centres

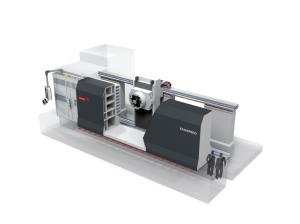

This high-speed machining center for long aluminium stringer components combines the advantages of Sprint-Z3 technology with rapidity and accuracy to provide efficient work piece machining with optimised workpiece handing. The machine is specially designed for machining aluminium profiles (or stringers) of up to 30 metres in length. Thanks to the excellent precision and speed the ECOLINER user can achieve high cutting rates (average machining time of 12 minutes per linear meter), optimum accuracy and excellent surface quality, even with extremely long stringers.

ECOSPEED

|

High speed machining centre

Starrag Technology GmbH

Horizontal machining centres

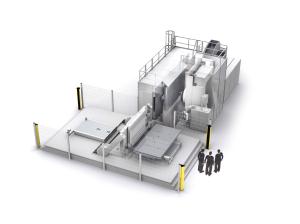

In the aviation industry, there is an increasing trend towards larger and larger monolithic structural components. The ECOSPEED series, featuring a horizontal spindle and a vertical pallet arrangement, has been specially developed for high-speed machining of these large structural aluminum components. A pallet transport system feeds pallets to the machine, the storage station and the loading/unloading station. The innovative Sprint Z3 parallel kinematic machining head, provides the user with the optimum 5-axis simultaneous machining process.

At a maximum cutting volume of up to 8,000 cm3/min, the machine concept is the world's most productive solution for cutting aluminium structural components, drastically cutting both production times and costs.

ECOSPEED F

|

High speed machining centre

Starrag Technology GmbH

Horizontal machining centres

Scharmann has developed the ECOSPEED F for high-speed machining of mediumsized aluminium structural components. The horizontal spindle arrangement, the vertical pallet arrangement and the Sprint Z3 parallel kinematic machining head, which delivers high travel speeds (50 m/min) and accelerations (9.81 m/s²), all come from the successful ECOSPEED.

What sets the F version apart from the standard ECOSPEED is that the machine column is stationary. The pallet travels in the X direction on the vertically arranged table group. The ECOSPEED F is equipped with a rotating double pallet station, located parallel to the X-axis, which enables component loading and unloading during the machining cycle.

ECOSPEED F HT2

|

High speed machining centre

Starrag Technology GmbH

Horizontal machining centres

This high-speed machining center is perfect for rapid cutting of small and mediumsized workpieces with maximum productivity. The critical innovation is the Sprint Z3 parallel kinematic machining head, which enables components to be produced with excellent dynamics and precision and an outstanding surface quality, at batch sizes of a single unit through to bulk production. The excellent machining and surface quality means that there is no need for the manual rework that is usually required with conventional machining centers. This results in increased efficiency, improved process reliability and long-term stability. The key features include 1,000 x 1,000 mm pallet size, up to 120 kW spindle power and rapid tool change, from either a chain or rack magazine.

The table with the work piece moves horizontally in the X-axis while the headstock traverses on the stationary column to provide Y-axis movement. Z-axis, A-axis and B-axis movement is provided by the Sprint Z3 head with an additional positioning axis provided by the rotary table.

Heckert Athletic Series

|

Horizontal machining centre

Starrag GmbH

Horizontal machining centres

Large machining center are ideal for rapid, cost-effective, complete machining of large and heavy workpieces (swing diameter up to 3,300 mm, maximum weight: 13,000 kg). The modular design provides maximum flexibility and allows tailored production solutions to be created. The center deliver high precision, process optimised and energy efficient machining of housings and prismatic workpieces, primarily in the agricultural machinery and the motor industry, equipment manufacture, pump and compressor production and the wind energy sector.

These Horizontal machining center are based on a very extensive modular concept. The modular design includes the major components, the tool and workpiece handling units, the design of the working spindles, with modified power and speed configurations, and the control options.

Heckert DBF 1000 / 1250

|

Horizontal machining centre

Starrag GmbH

Horizontal machining centres

The DBF 1000 / 1250 enable complete machining in one clamping position, hence the name DBF (which stands for turning-drilling-milling in German) which has a decisive effect on the productivity of the overall production system. The working spindle of the DBF heads carries out all the machining on the tool that is attached. When turning is required on a clamped work piece, the rotating lathe tool can be radially shifted by ± 35 mm (servo-axis).

Balancing weights integrated in the head compensate for the imbalance set off by the balanced tools, which means that up to 1,200 rpm is possible for turning work.

For boring and milling, a 35/45 kW spindle achieves speeds of up to 3,500 rpm. The DBF 1000 / 1250 enables complete machining with a consistent axial and radial run-out of 5 - 6 µm on the part, which reduces the time and other effort required for clasping, temporary storage and new setting-up each time.

Heckert DBF 630 / 800

|

Horizontal machining centre

Starrag GmbH

Horizontal machining centres

The DBF 630 / 800 enable complete machining in one clamping position, hence the name DBF (which stands for turning-drilling-milling in German) which has a decisive effect on the productivity of the overall production system. The working spindle of the DBF heads carries out all the machining on the tool that is attached. When turning is required on a clamped work piece, the rotating lathe tool can be radially shifted by ± 35 mm (servo-axis).

The HEC 630/800 Athletic machining centers are the base system concept. The DBF head enables complete machining with a consistent axial and radial run-out of 5-6 µm on the part. The imbalance of the valve plate is compensated by a counterweight, allowing turning speeds up to 1200 r.p.m.

SIP 7000

|

Ultra precise horizontal machining centre

Starrag Vuadens SA

Horizontal machining centres

Ever since it was founded in 1862, the Geneva-based Société d?Instruments de Précision (SIP) has been a benchmark for precision machine tool engineering. The basic design of SIP machines can still be found today in all traditional machining centers, both for vertical and horizontal models.

SIP 7000/7 (4 and 5 axis)

The horizontal SIP machining centers are living proof that ultra-precision is by no means a myth. Gearbox housings, spindle heads and two-axis turntables can be machined with significantly higher levels of precision than with conventional machining centers, making them the obvious choice for customers.

SIP SPC

|

Horizontal machining centre

Starrag Vuadens SA

Horizontal machining centres

he SIP SPC Series not only provides the user with the ultimate in precision but also with tried and tested sophisticated automation. Investment in SIP technology produces returns, thanks to above-average long-term precision and many years of durability.