Starrag Group

Products

Starrag AG

Universal machining centres

Heckert HEC 500 / 630 / 800 Athletic

The medium-sized all round machining centers guarantee maximum efficiency, high machining quality and reliability for the entire metal working industry. The modular design of the centers ensures maximum flexibility and allows optimised manufacturing solutions to be created. Customers can choose between three different working spindles, various tool magazines and a wide range of special designs and accessories.

Droop+Rein G/GF

|

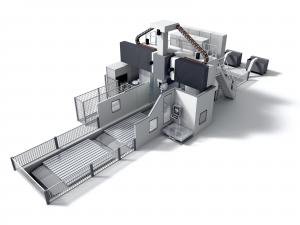

portal machining center in gantry design

Starrag Technology GmbH

Universal machining centres

The advantage of machining large, heavy and unwieldy components on a gantry type machine is that the component mass has no effect on the machining process. Droop+Rein created the G/GF series for just such difficult tasks. The gantry machines reliably prevent dynamic loss when supporting and accelerating these high loads. To cope with its demanding machining tasks, the G/GF series boasts many technical highlights, for example, hydrostatic guides on all the linear axes, the thermo-symmetrical construction of the ram-type milling unit and the integral C-axis. Automatic milling head, spindle and tool changing are available by the integration of standard, well proven, expansion modules.

Droop+Rein T/TF

|

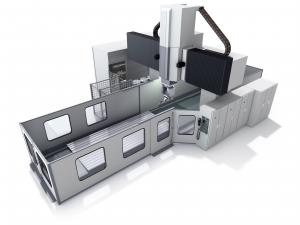

portal machining center

Starrag Technology GmbH

Universal machining centres

With its T/TF portal machining center series Droop+Rein supply heavy duty cutting applications for many industries. The range extends from tool making and mould and die, aircraft component production, engine manufacture and through to general engineering applications. Based on stable, extremely accurate and high performance base machines, the T/TF series offers a very comprehensive system for innovative automation. With the addition of various expansion modules the T/TF range can be adapted very easily to any machining task.

Optional automatic milling head, spindle and tool changing units enable complex and demanding machining routines to be performed. Due to Droop+Rein?s extensive applications expertise a wide variety of different milling heads are available, vertical heads, angled heads as well as fork-type milling heads for positionable or simultaneously controlled applications.

Droop+Rein TFS

|

portal machining center

Starrag Technology GmbH

Universal machining centres

For machine manfacturers and toolmakers, flexibility, cost effectiveness and precision play a very important role, especially when machining large components. These three requirements are what led to the development of the TFS portal machining center with its fixed cross-rail. Customers use the modular principle to select the table configuration, control systems and milling units appropriate to their individual tasks. The flexible D40 ram-type milling unit with its integral C-axis, provides a stable platform for our wide range of milling heads, from a conventional vertical spindle through fixed angle heads and on to 3+2 axis and full 5-axis contouring.

The large number of well proven, automatically exchangeable milling heads increases the range of suitable applications. The TFS range of attachments also includes automatic spindle changing as well as tool and component measurement.