Supertec Machinery

Products

Your Finest Soulation

Grinding machines

Centreless grinding machines

Centerless Grinder

|

STC-12, STC-18/20, STC-24

Supertec Machinery, Inc.

Centreless grinding machines

DESCRIPTION

Both grinding & regulating wheel spindles are made of NI-CR-MO alloy steel, which is normalized and carbonized hardened and ground for longer spindle life and better accuracy.

Hydrostatic Babbitt bearings type spindle with a 3-point support design, surrounded by a high pressure oil film, eliminates metal-to-metal contact to provide heavy duty grinding capability as well as high vibration damping performance.

A pressure switch interlock prevents spindle start-up until oil pressure is established. This pressure switch interlock also stops the spindle if oil pressure fails for longer spindle life.

The regulating wheel travels on double V ways are hand-scraped and Turcite coated for precise and smooth movement to ensure high accuracy and longer way life.

Both grinding & regulating wheels equip with hydraulic dressing unit. Dressing speed is infinitely variable. Various profile dressing can be achieved with optional template.

Hydraulic dressing unit for the regulating wheel can be rapidly and precisely swiveled up to ±3°for grinding taper in infeed grinding and for providing better contact between workpiece and grinding wheel to achieve better surface roughness, roundness, & cylindricity.

All gears in the gearbox are made of Chrome-Molybdenum alloy steel (SNCM-21), are hardened and precision-ground for smooth running and low noise.

The hydraulic system is air cooled to maintain constant oil temperature and separated from machine to eliminate vibration and dissipate heat.

Optional automatic loading & unloading for infeed & thrufeed can be custom-built to meet your requirements, so machine can run unattended, at a high production rate, while maintaining a tight tolerance.

Both grinding & regulating wheel spindles are made of NI-CR-MO alloy steel, which is normalized and carbonized hardened and ground for longer spindle life and better accuracy.

Hydrostatic Babbitt bearings type spindle with a 3-point support design, surrounded by a high pressure oil film, eliminates metal-to-metal contact to provide heavy duty grinding capability as well as high vibration damping performance.

A pressure switch interlock prevents spindle start-up until oil pressure is established. This pressure switch interlock also stops the spindle if oil pressure fails for longer spindle life.

The regulating wheel travels on double V ways are hand-scraped and Turcite coated for precise and smooth movement to ensure high accuracy and longer way life.

Both grinding & regulating wheels equip with hydraulic dressing unit. Dressing speed is infinitely variable. Various profile dressing can be achieved with optional template.

Hydraulic dressing unit for the regulating wheel can be rapidly and precisely swiveled up to ±3°for grinding taper in infeed grinding and for providing better contact between workpiece and grinding wheel to achieve better surface roughness, roundness, & cylindricity.

All gears in the gearbox are made of Chrome-Molybdenum alloy steel (SNCM-21), are hardened and precision-ground for smooth running and low noise.

The hydraulic system is air cooled to maintain constant oil temperature and separated from machine to eliminate vibration and dissipate heat.

Optional automatic loading & unloading for infeed & thrufeed can be custom-built to meet your requirements, so machine can run unattended, at a high production rate, while maintaining a tight tolerance.

Internal grinding machines

3-Axes Complex CNC internal Grinder

|

Internal grinding machine

Supertec Machinery, Inc.

Internal grinding machines

GM-series

3-Axes Complex CNC Internal Grinder

3-Axes Complex CNC Internal Grinder uses Computer-aided Numerical Controller to control the workhead (X axis),ID/OD wheelhead (W axis) and ID wheelhead (Z axis).With one time chucking action , the Grindmaster 45can perform complex and precision grinding operations, ie : internal diameter, outside diameter, shoulder grinding, taper grinder and end-surface grinding …etc.

Grinding Operation Example:

Internal diameter straight grinding operation / Outside diameter straight grinding operation.

Internal diameter taper grinding operation / Outside diameter straight grinding operation.

Internal diameter straight grinding operation / Outside diameter aper grinding operation.

The closed-loop system design of X-axis ensure high precision requirement for grinding operation. Further more, auto sizing devices can be chosen to reinforce accuracy performance of Grindmaster 45. Evolutional design of the W-axis swiveling function makes Grindmaster 45 meet the flexibility requirements of job shop manufacturing.

3-Axes Complex CNC Internal Grinder uses Computer-aided Numerical Controller to control the workhead (X axis),ID/OD wheelhead (W axis) and ID wheelhead (Z axis).With one time chucking action , the Grindmaster 45can perform complex and precision grinding operations, ie : internal diameter, outside diameter, shoulder grinding, taper grinder and end-surface grinding …etc.

Grinding Operation Example:

Internal diameter straight grinding operation / Outside diameter straight grinding operation.

Internal diameter taper grinding operation / Outside diameter straight grinding operation.

Internal diameter straight grinding operation / Outside diameter aper grinding operation.

The closed-loop system design of X-axis ensure high precision requirement for grinding operation. Further more, auto sizing devices can be chosen to reinforce accuracy performance of Grindmaster 45. Evolutional design of the W-axis swiveling function makes Grindmaster 45 meet the flexibility requirements of job shop manufacturing.

Internal Grinder

|

Internal grinding machine

Supertec Machinery, Inc.

Internal grinding machines

3-Axes Complex CNC Internal Grinder

3-Axes Complex CNC Internal Grinder uses Computer-aided Numerical Controller to control the workhead (X axis),ID/OD wheelhead (W axis) and ID wheelhead (Z axis).With one time chucking action , the Grindmaster 45can perform complex and precision grinding operations, ie : internal diameter, outside diameter, shoulder grinding, taper grinder and end-surface grinding …etc.

Grinding Operation Example:

Internal diameter straight grinding operation / Outside diameter straight grinding operation.

Internal diameter taper grinding operation / Outside diameter straight grinding operation.

Internal diameter straight grinding operation / Outside diameter aper grinding operation.

The closed-loop system design of X-axis ensure high precision requirement for grinding operation. Further more, auto sizing devices can be chosen to reinforce accuracy performance of Grindmaster 45. Evolutional design of the W-axis swiveling function makes Grindmaster 45 meet the flexibility requirements of job shop manufacturing.

GI-150CNC Series

CNC controlling 2 axis of table left, right feed and grinding wheel federate. X-axis closed-loop design, applying 0..05μm resolution linear scale to ensure the positioning and repeatability accuracy of the feeding axis.

Apply linear guide that enables fine feed of 0.1μm, the minimum setting unit of both table guide face and cut guide face. By improving position definition and repetition accuracy, power on edge face and dead-end grinding is brought out.

With certain tension and regardless to grinding resistance, belt of grinding wheel spindle is expanded and without slippage that its rotation accuracy is improved.

Chuck core is as low as 1000mm,change such as work disconnection, grinding wheel replacement is easy and without troublesome.

3-Axes Complex CNC Internal Grinder uses Computer-aided Numerical Controller to control the workhead (X axis),ID/OD wheelhead (W axis) and ID wheelhead (Z axis).With one time chucking action , the Grindmaster 45can perform complex and precision grinding operations, ie : internal diameter, outside diameter, shoulder grinding, taper grinder and end-surface grinding …etc.

Grinding Operation Example:

Internal diameter straight grinding operation / Outside diameter straight grinding operation.

Internal diameter taper grinding operation / Outside diameter straight grinding operation.

Internal diameter straight grinding operation / Outside diameter aper grinding operation.

The closed-loop system design of X-axis ensure high precision requirement for grinding operation. Further more, auto sizing devices can be chosen to reinforce accuracy performance of Grindmaster 45. Evolutional design of the W-axis swiveling function makes Grindmaster 45 meet the flexibility requirements of job shop manufacturing.

GI-150CNC Series

CNC controlling 2 axis of table left, right feed and grinding wheel federate. X-axis closed-loop design, applying 0..05μm resolution linear scale to ensure the positioning and repeatability accuracy of the feeding axis.

Apply linear guide that enables fine feed of 0.1μm, the minimum setting unit of both table guide face and cut guide face. By improving position definition and repetition accuracy, power on edge face and dead-end grinding is brought out.

With certain tension and regardless to grinding resistance, belt of grinding wheel spindle is expanded and without slippage that its rotation accuracy is improved.

Chuck core is as low as 1000mm,change such as work disconnection, grinding wheel replacement is easy and without troublesome.

Other grinding machines

Vertical Grinder

|

Other grinding machine

Supertec Machinery, Inc.

Other grinding machines

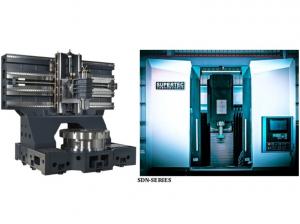

Supertec's SDN Series holds one of the highest standard of solutions.

Stepping up the game to a whole new level

This machine can complete all three OD ID & End face grinding in one chucking for HEAVY or NON-CIRCULAR work pieces.

The SDN Series is made for Heavier work pieces, it can EASILY be loaded to the machine by the overhead hoist.

Fully enclosed covers and oil mist reclaiming guarantees to keep the factory and the machine nice and clean.

Options : 1. single/double-spindle with or without tool changer.

Fanuc controller plus 10" screen man-machine touch panel.

Simple conversational operating system all programmed and allows machinist to machine workpiece with instinct.

Stepping up the game to a whole new level

This machine can complete all three OD ID & End face grinding in one chucking for HEAVY or NON-CIRCULAR work pieces.

The SDN Series is made for Heavier work pieces, it can EASILY be loaded to the machine by the overhead hoist.

Fully enclosed covers and oil mist reclaiming guarantees to keep the factory and the machine nice and clean.

Options : 1. single/double-spindle with or without tool changer.

Fanuc controller plus 10" screen man-machine touch panel.

Simple conversational operating system all programmed and allows machinist to machine workpiece with instinct.

Vertical Grinder

|

Other grinding machine

Supertec Machinery, Inc.

Other grinding machines

Supertec's SDN Series holds one of the highest standard of solutions.

Stepping up the game to a whole new level

This machine can complete all three OD ID & End face grinding in one chucking for HEAVY or NON-CIRCULAR work pieces.

The SDN Series is made for Heavier work pieces, it can EASILY be loaded to the machine by the overhead hoist.

Fully enclosed covers and oil mist reclaiming guarantees to keep the factory and the machine nice and clean.

Options : 1. single/double-spindle with or without tool changer.

Fanuc controller plus 10" screen man-machine touch panel.

Simple conversational operating system all programmed and allows machinist to machine workpiece with instinct.

Stepping up the game to a whole new level

This machine can complete all three OD ID & End face grinding in one chucking for HEAVY or NON-CIRCULAR work pieces.

The SDN Series is made for Heavier work pieces, it can EASILY be loaded to the machine by the overhead hoist.

Fully enclosed covers and oil mist reclaiming guarantees to keep the factory and the machine nice and clean.

Options : 1. single/double-spindle with or without tool changer.

Fanuc controller plus 10" screen man-machine touch panel.

Simple conversational operating system all programmed and allows machinist to machine workpiece with instinct.

Plain cylindrical grinding machines

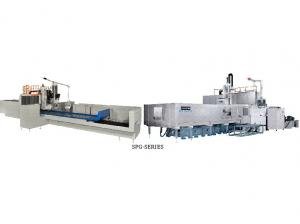

CNC Double Column Surface Grinder

|

SPG-Series

Supertec Machinery, Inc.

Plain cylindrical grinding machines

CNC Double Column Surface Grinder

All major parts are casting (FC300, heat treated)

Machine base is a one-piece casting.

Several brackets inside the base contributing to great rigidity.

Machine leveling can be as easy as turning a bolt on the adjustable pad.

Bellows to protect the guide ways

High precision couplings on the wheelhead prevent slip and vibration.

X- axis: Hydrodynamic lubrication on the double V guide ways assuring non-wear out.

Y & Z axis : Box guide ways with forced lubrication ensuring precision, rigidity, and less frication.

Independent electrical cabinet with heat exchanger and light.

Coolant system is equipped with paper filter and magnetic separator.

Auto oil feeder on ballscrews provides timed lubrication.

Machine base is a one-piece casting, Leaking is out of the question.

The CNC control has both RS232 and CF port, DATA could be saved outside of the machine.

Various CNC grinding programs packed in.

Machine base is a one-piece casting.

Several brackets inside the base contributing to great rigidity.

Machine leveling can be as easy as turning a bolt on the adjustable pad.

Bellows to protect the guide ways

High precision couplings on the wheelhead prevent slip and vibration.

X- axis: Hydrodynamic lubrication on the double V guide ways assuring non-wear out.

Y & Z axis : Box guide ways with forced lubrication ensuring precision, rigidity, and less frication.

Independent electrical cabinet with heat exchanger and light.

Coolant system is equipped with paper filter and magnetic separator.

Auto oil feeder on ballscrews provides timed lubrication.

Machine base is a one-piece casting, Leaking is out of the question.

The CNC control has both RS232 and CF port, DATA could be saved outside of the machine.

Various CNC grinding programs packed in.

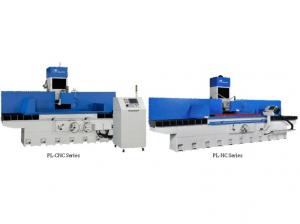

PL-CNC/NC Series

|

Surface Grinder (Column type)

Supertec Machinery, Inc.

Plain cylindrical grinding machines

Surface Grinder PL-Series (Column type)

All essential castings are rib reinforced to provide a rigid machine structure for long lasting accuracy and stability.

The precision cartridge spindle equipped with 4 pieces of preloaded class 7 (p4) super precision angular contact ball bearings to ensure high accuracy and superior grinding finish.

Spindle, couplings, and spindle motor (15HP) are precisely balanced for low vibration and powerful output to achieve precision grinding accuracy.

Rigid table with box-type structure travels on a cushion of oil with no metal-to-metal contact to provide excellent way longevity.

Column guideways are Turcite-B coated and precisely hand scraped to provide a smooth movement for better accuracy and longer way life.

The rigid wheelhead travels on wide contact hardened and ground guideways and is precisely positioned with a stepping motor to ensure better downfeed repeatability.

Crossfeed mechanism incorporate with a precision ball screw, AC inverter provides smooth accurate crossfeed and allows criss-cross grinding for better grinding surface finish.

Hydraulic, coolant and lubrication systems are separated from machine to eliminate vibration and dissipate heat. Heat exchange is used on hydraulic system to maintain normal temperature of hydraulic oil.

All moving surfaces and rotating parts are continuously lubricated by an auto-lube system to ensure long service life and maintain maximum accuracy. An alarm light will illuminate if oil pressure drops below present pressure.

Positioning accuracy and repeatability is assured with an AC servo motor and high precision pre-tensioned ballscrew.

STP-Series

|

Surface Grinder (Saddle type)

Supertec Machinery, Inc.

Plain cylindrical grinding machines

Surface Grinder STP-Series

3 HP V3 grade spindle motor for powerful output to achieve precision work standards and better grinding capability.

Cartridge spindle w/4 preloaded class 7(p4) bearings and run-out of taper nose better than 0.000060” T.I.R. provides quiet, vibration free operation for better work pieces accuracy.

Optional 0.000050” micro down feed and micro cross feed.

Ergonomic vertical handwheel are designed at the waist level height.

The steel ball way table travels and ground guide ways ensures smooth, easy movement of table.

Double V cross ways are hand scraped and Turcite coated for absolute flatness and high wear resistance.

All castings are tempered and stress relieved twice to assure stability of the machine structure and resist deflection under load.

Hardened & ground column ways with cast spindle slide is precision fit for no “hang-up” gravity downfeed.

PLC control uses a menu-driven LCD touch screen is easy to learn and easy to set. Simply fill in the blanks to set total grinding amount, rough increment, fine increment, sparkout passes, feeding direction, parking position, wheelhead retract distance, and press cycle start to complete automatic grinding cycle. (CII models only)

Grinding cycles for CII model: semi-automatic, surface, plunge, & crisscross.

Index table handwheel for ease of operation.(618M only)

Work table flatness shall be within 0.00012”.

The table reversal is actuated by non-contact proximity switches, and hydraulically powered, table speed is infinitely variable.(except 618M)

The automatic lubrication system continuously floods saddle & column ways, bearings, and lead screws for better machine performance and less maintenance.

Cartridge spindle w/4 preloaded class 7(p4) bearings and run-out of taper nose better than 0.000060” T.I.R. provides quiet, vibration free operation for better work pieces accuracy.

Optional 0.000050” micro down feed and micro cross feed.

Ergonomic vertical handwheel are designed at the waist level height.

The steel ball way table travels and ground guide ways ensures smooth, easy movement of table.

Double V cross ways are hand scraped and Turcite coated for absolute flatness and high wear resistance.

All castings are tempered and stress relieved twice to assure stability of the machine structure and resist deflection under load.

Hardened & ground column ways with cast spindle slide is precision fit for no “hang-up” gravity downfeed.

PLC control uses a menu-driven LCD touch screen is easy to learn and easy to set. Simply fill in the blanks to set total grinding amount, rough increment, fine increment, sparkout passes, feeding direction, parking position, wheelhead retract distance, and press cycle start to complete automatic grinding cycle. (CII models only)

Grinding cycles for CII model: semi-automatic, surface, plunge, & crisscross.

Index table handwheel for ease of operation.(618M only)

Work table flatness shall be within 0.00012”.

The table reversal is actuated by non-contact proximity switches, and hydraulically powered, table speed is infinitely variable.(except 618M)

The automatic lubrication system continuously floods saddle & column ways, bearings, and lead screws for better machine performance and less maintenance.

Production external cylindrical grinding machines

CNC CYLINDRICAL GRINDER (ANGULAR TYPE)

|

Production external cylindrical grinding machine

Supertec Machinery, Inc.

Production external cylindrical grinding machines

G32A/G38A-35/50 CNC Series

Machine Base The heavily ribbed box-type base is made of Meehanite casting, providing excellent rigidity to ensure machine stability. Optimum distance between the guideways offers excellent table support to increase Z axis positioning accuracy and repeatability. Work head The sturdy rigid-designed workhead equipped with precision bearings is electronically controlled giving variable spindle speeds. Workhead swivels 90°counterclockwise to 30°clockwise for various grinding operations. A combination live and dead-type spindle allows for quick changeover from center to chuck operation or vice versa. A dual oil seal and cover prevent coolant seepage into the workhead. Tailstock The design of the tailstock is both rigid and robust. Housed in a Meehanite case body, the hardened nitralloy steel sleeve is designed to carry a MT4 center for G32A/G38A. Movement of the sleeve is adjusted by a knob to give a light or heavy load.

Wheel Head

PMG series use the wheel head (Automatic B-axis) with 2 OD wheels and 1 ID wheel, for performing complex grinding operations, such as OD / Taper / ID grinding operations, under one setup to reduce cycle time, operation costs, and get better accuracy performances..

CNC controlled wheel head (B-axis) with servo motor output 1.2 kw

B-axis (±2.0”)PR or (±5.0”), can equipped with either Heidenhain or Fagor encoder.

OD spindle motor output 5HP, equipped with CE certified safety cover

OD wheel size (LHS) Ø405x 50 xØ127 mm

OD wheel size (RHS) Ø305 x 25 xØ127 mm

Special Coolant System design

Coolant flow through the whole machine via nozzle system during the grinding operation. Extra heat will be taken away to prevent transformation, ensure the accuracy performance. Grinding chips will be washed away by the current to keep the cleanness of the machine

Wheel Head

PMG series use the wheel head (Automatic B-axis) with 2 OD wheels and 1 ID wheel, for performing complex grinding operations, such as OD / Taper / ID grinding operations, under one setup to reduce cycle time, operation costs, and get better accuracy performances..

CNC controlled wheel head (B-axis) with servo motor output 1.2 kw

B-axis (±2.0”)PR or (±5.0”), can equipped with either Heidenhain or Fagor encoder.

OD spindle motor output 5HP, equipped with CE certified safety cover

OD wheel size (LHS) Ø405x 50 xØ127 mm

OD wheel size (RHS) Ø305 x 25 xØ127 mm

Special Coolant System design

Coolant flow through the whole machine via nozzle system during the grinding operation. Extra heat will be taken away to prevent transformation, ensure the accuracy performance. Grinding chips will be washed away by the current to keep the cleanness of the machine

Universal cylindrical grinding machines

CNC UNIVERSAL CYLINDRICAL GRINDER

|

PMG-CNC Series

Supertec Machinery, Inc.

Universal cylindrical grinding machines

PMG-60/100CNC(A/B)

Wheel Head: PMG series use the wheel head (Automatic B-axis) with 2 OD wheels and 1 ID wheel, for performing complex grinding operations, such as OD / Taper / ID grinding operations, under one setup to reduce cycle time, operation costs, and get better accuracy performances. CNC controlled wheel head (B-axis) with servo motor output 1.2 kw B-axis swivel range from 35° CCW to195° CW OD spindle motor output 5HP, equipped with CE certified safety cover OD wheel size (LHS) Ø405 x 50 xØ127 mm OD wheel size (RHS) Ø355 x 38 xØ127 mm CNC program controlled wheel rotation shifting mechanism (15 levels), ensure cutting capacity Special Coolant System design: Coolant flow through the whole machine via nozzle system during the grinding operation. Extra heat will be taken away to prevent transformation, ensure the accuracy performance. Grinding chips will be washed away by the current to keep the cleanness of the machine.

GP-CNC Series

|

Plunge Type Cylindrical Grinder

Supertec Machinery, Inc.

Universal cylindrical grinding machines

GP-CNC Series

Machine Base

The heavily ribbed box-type base is made of Meehanite casting, providing excellent rigidity to ensure machine stability. Optimum distance between the guideways offers excellent table support to increase Z axis positioning accuracy and repeatability.

Workhead

The sturdy rigid-designed workhead equipped with precision bearings is electronically controlled giving variable spindle speeds. Workhead swivels 90°counterclockwise to 30°clockwise for various grinding operations. A combination live and dead-type spindle allows for quick changeover from center to chuck operation or vice versa. A dual oil seal and cover prevent coolant seepage into the workhead.

Tailstock

The design of the tailstock is both rigid and robust. Housed in a Meehanite case body, the hardened nitralloy steel sleeve is designed to carry a MT3 center for G20P/G25P. Movement of the sleeve is adjusted by a knob to give a light or heavy load. An optional hydraulic tailstock with foot pedal is available for easy loading and unloading of parts.

Wheel Spindle

Combinations of hydrostatic and hydrodynamic bearings are surrounded by a high pressure oil film, which eliminates metal-to-metal contact and provide high rigidity as well as high vibration damping performance. A pressure switch interlock prevents spindle start-up until oil pressure is established. The pressure switch interlock also stops the spindle if oil pressure fails. Both features ensure high accuracy and longer spindle life.

Saddle

Both the double V and flat guideways are hand scraped and Turcite coated, and utilize an automatic lubrication system, precision ballscrew, AC servo motor and a 0.001mm (0.000020”) linear feedback system. This combination allows for a smooth movement of the wheelhead which delivers a longer way life with superior positioning accuracy and repeatability. The enlarged and properly sloped drainage troughs under the wheelhead base help to control thermal growth and provides the rapid coolant drainage needed during heavy grinding cycles.

Automatic Lubrication System

Slideways, ballscrews and spindle are continuously lubricated by an auto-lube system to ensure long service life and maintain maximum accuracy. Hydraulics coolant and lubrication systems are separated from machine to eliminate vibration and dissipate heat.

System for Automation

A highly-automated grinding system can be customized with a wide selection of optional equipment including an automatic OD sizing device, gap control, crash control and touch probe for axial positioning.

Optional Internal Grinding Attachment

The hinged, swing-down internal grinding attachment swings down into working position easily and quickly. A patented locking device adds safety as it prevents the ID attachment from swinging down abruptly.

Universal Cylindrical Grinder PMG Series

PMG series use the wheel head (Automatic B-axis) with 2 OD wheels and 1 ID wheel, for performing complex grinding operations, such as OD / Taper / ID grinding operations, under one setup to reduce cycle time, operation costs, and get better accuracy performances..

CNC controlled wheel head (B-axis) with servo motor output 1.2 kw

B-axis (±2.0”)PR or (±5.0”), can equipped with either Heidenhain or Fagor encoder.

OD spindle motor output 5HP, equipped with CE certified safety cover

OD wheel size (LHS) Ø405x 50 xØ127 mm

OD wheel size (RHS) Ø305 x 25 xØ127 mm

Special Coolant System design

Coolant flow through the whole machine via nozzle system during the grinding operation. Extra heat will be taken away to prevent transformation, ensure the accuracy performance. Grinding chips will be washed away by the current to keep the cleanness of the machine

Machine Base

The heavily ribbed box-type base is made of Meehanite casting, providing excellent rigidity to ensure machine stability. Optimum distance between the guideways offers excellent table support to increase Z axis positioning accuracy and repeatability.

Workhead

The sturdy rigid-designed workhead equipped with precision bearings is electronically controlled giving variable spindle speeds. Workhead swivels 90°counterclockwise to 30°clockwise for various grinding operations. A combination live and dead-type spindle allows for quick changeover from center to chuck operation or vice versa. A dual oil seal and cover prevent coolant seepage into the workhead.

Tailstock

The design of the tailstock is both rigid and robust. Housed in a Meehanite case body, the hardened nitralloy steel sleeve is designed to carry a MT3 center for G20P/G25P. Movement of the sleeve is adjusted by a knob to give a light or heavy load. An optional hydraulic tailstock with foot pedal is available for easy loading and unloading of parts.

Wheel Spindle

Combinations of hydrostatic and hydrodynamic bearings are surrounded by a high pressure oil film, which eliminates metal-to-metal contact and provide high rigidity as well as high vibration damping performance. A pressure switch interlock prevents spindle start-up until oil pressure is established. The pressure switch interlock also stops the spindle if oil pressure fails. Both features ensure high accuracy and longer spindle life.

Saddle

Both the double V and flat guideways are hand scraped and Turcite coated, and utilize an automatic lubrication system, precision ballscrew, AC servo motor and a 0.001mm (0.000020”) linear feedback system. This combination allows for a smooth movement of the wheelhead which delivers a longer way life with superior positioning accuracy and repeatability. The enlarged and properly sloped drainage troughs under the wheelhead base help to control thermal growth and provides the rapid coolant drainage needed during heavy grinding cycles.

Automatic Lubrication System

Slideways, ballscrews and spindle are continuously lubricated by an auto-lube system to ensure long service life and maintain maximum accuracy. Hydraulics coolant and lubrication systems are separated from machine to eliminate vibration and dissipate heat.

System for Automation

A highly-automated grinding system can be customized with a wide selection of optional equipment including an automatic OD sizing device, gap control, crash control and touch probe for axial positioning.

Optional Internal Grinding Attachment

The hinged, swing-down internal grinding attachment swings down into working position easily and quickly. A patented locking device adds safety as it prevents the ID attachment from swinging down abruptly.

Universal Cylindrical Grinder PMG Series

PMG series use the wheel head (Automatic B-axis) with 2 OD wheels and 1 ID wheel, for performing complex grinding operations, such as OD / Taper / ID grinding operations, under one setup to reduce cycle time, operation costs, and get better accuracy performances..

CNC controlled wheel head (B-axis) with servo motor output 1.2 kw

B-axis (±2.0”)PR or (±5.0”), can equipped with either Heidenhain or Fagor encoder.

OD spindle motor output 5HP, equipped with CE certified safety cover

OD wheel size (LHS) Ø405x 50 xØ127 mm

OD wheel size (RHS) Ø305 x 25 xØ127 mm

Special Coolant System design

Coolant flow through the whole machine via nozzle system during the grinding operation. Extra heat will be taken away to prevent transformation, ensure the accuracy performance. Grinding chips will be washed away by the current to keep the cleanness of the machine