VOLMATEC

Products

Milling machines

Universal bed type milling machines

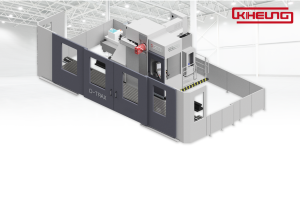

KIHEUNG KNC U 1250 BT

|

Universal bed type milling machine

VOLMATEC / KIHEUNG

Universal bed type milling machines

| mm | |

| mm | |

| mm |

The successful, compact universal bed type milling machines of the KIHEUNG KNC U - machine series are the ideal milling machines for high chip volume and excellent geometrical manufacturing accuracy, equipped with the latest HEIDENHAIN TNC 640 CNC control.

Due to the innovative FLAT-Ram machine design, where all drive and transmission units, such as spindle motor, ZF-gearbox or belt pulley are placed on the rear area of the arm, the KNC U series achieves a geometrical accuracy that is almost unique in this machine class.

- HEIDENHAIN TNC 640 contouring control with MC 7522 main computer including software option I

- Milling head, ZF gearbox and drive spindle cooling via oil circulation

- Cooling of the Y-axes ball screws via oil circulation

- Universal vertical milling head system HURON

- Chip conveyor rear

- Linear Measuring System via HEIDENHAIN Scales with DA 400 Compressed Air System

- SIEMENS® / HEIDENHAIN Main spindle motor 28/38 KW

- AC Drives HEIDENHAIN

- ZF reduction gear cooled, 2-stage (1 - 1,000 / 1,001 - 4,000 rpm)

- hydraulic weight compensation in the Z-axis

- Spindle orientation for rigid tapping

- Preparation of the PLC for a 4th axis

- automatic blow-out unit of the cone - automatic milling heads

- Electronic portable handwheel HEIDENHAIN HR 410

- Compressed air through nozzle ring via M-function

- Air through the spindle, max. 10 bar, controlled via M-function

- automatic central lubrication

- Workspace cladding with partly multi-layer doors and windows according to CE

- Safety enclosure of the rear machine area via fence and sheet metal system with secured inspection openings

- Coolant system via nozzle ring, 8 bar with large-volume tank

- with option cooling by spindle 1 main tank and 1 pre-tank

- Preparation of the PLC for HEIDENHAIN TS 260 workpiece measuring system and for HEIDENHAIN TT 160 tool touch probe

- RITTAL switch cabinet with RITTAL air conditioning

- Operating and working light

- Tightening bolts, anchor bolts and pressure plates

- CE safety equipment

- Documentations

- Paint: Light grey RAL 7035, carmine red RAL 3002, slate grey RAL 7015

Product video: Here along

Translated with DeepL

KIHEUNG KNC U 1500 BT

|

Universal bed type milling machine

VOLMATEC / KIHEUNG

Universal bed type milling machines

| mm | |

| mm | |

| mm |

Flat-guided bed-type milling machines for heavy cutting with nevertheless good dynamics and high-precision geometry - ideal also for boring mill work!

Translated with DeepL

KIHEUNG KNC U 1000 LT

|

Universal bed type milling machine

VOLMATEC / KIHEUNG

Universal bed type milling machines

| mm | |

| mm | |

| mm |

Product video: Here along

The linear guided universal bed type milling machines KNC LT are based on the successful KIHEUNG KNC machine series. The KIHEUNG KNC LT - machine series are the ideal milling machines for a high chip volume and at the same time excellent geometrical manufacturing accuracy, equipped with the latest HEIDENHAIN TNC 640 CNC control.

Due to the innovative FLAT-Ram machine design, where all drive and transmission units, such as spindle motor, ZF-gearbox or belt pulley are placed on the rear area of the arm, the KNC U series achieves a geometrical accuracy that is almost unique in this machine class.

- HEIDENHAIN TNC 640 contouring control with MC 7522 main computer including software option I

- Milling head, ZF gearbox and drive spindle cooling via oil circulation

- Cooling of the Y-axes ball screws via oil circulation

- Universal vertical milling head system HURON

- Chip conveyor rear

- INA precision linear guides in all 3 axes

- Linear Measuring System via HEIDENHAIN Scales with DA 400 Compressed Air System

- SIEMENS / HEIDENHAIN Main spindle motor 28/42 KW

- AC drives SIEMENS

- ZF reduction gear cooled, 2-stage (1 - 1,000 / 1,001 - 4,000 rpm)

- hydraulic weight compensation in the Z-axis

- additional foot switch at the back of the machine for tool change

- Spindle orientation for rigid tapping

- Preparation of the PLC for a 4th axis

- automatic blow-out unit of the cone - automatic milling heads

- Electronic portable handwheel HEIDENHAIN HR 410

- Compressed air through nozzle ring via M-function

- Air through the spindle, max. 10 bar, controlled via M-function

- automatic central lubrication

- Workspace cladding with partly multi-layer doors and windows according to CE

- Safety enclosure of the rear machine area via fence and sheet metal system with secured inspection openings

- Coolant system via nozzle ring, 8 bar with large-volume tank

- with option cooling by spindle 1 main tank and 1 pre-tank

- Preparation of the PLC for HEIDENHAIN TS 260 workpiece measuring system and for HEIDENHAIN TT 160 tool touch probe

- RITTAL switch cabinet with RITTAL air conditioning

- Operating and working light

- Tightening bolts, anchor bolts and pressure plates

- CE safety equipment

- Documentations

- Paint: Light grey RAL 7035, carmine red RAL 3002, slate grey RAL 7015

To the overview of our bed type milling machines

Translated with DeepL

KIHEUNG KNC U 1350 LT - Dynamik-Line

|

Universal bed type milling machine

VOLMATEC / KIHEUNG

Universal bed type milling machines

| mm | |

| mm | |

| mm |

Linear guided bed-type milling machines for dynamic machining with large traverse ranges and elaborate 3-fold cantilever guidance for high chip removal rates.

Translated with DeepL

KIHEUNG KNC U 1000 / 1250 ECO

|

Universal bed type milling machine

VOLMATEC / KIHEUNG

Universal bed type milling machines

| mm | |

| mm | |

| mm |

The successful, compact universal bed type milling machines of the KIHEUNG KNC U - machine series are the ideal milling machines for high chip volume and excellent geometrical manufacturing accuracy, equipped with the latest HEIDENHAIN TNC 640 CNC control.

Due to the innovative FLAT-Ram machine design, where all drive and transmission units, e.g. spindle motor, ZF gearbox or belt pulley are placed on the rear area of the arm, the KNC U series achieves a geometrical accuracy that is almost unique in this machine class.

Machine Highlights / Equipment:

- VOLMATEC remote diagnostics including HEIDENHAIN dongle

- Contouring control HEIDENHAIN TNC 640 or SIEMENS 840D

- Electronic portable handwheel HEIDENHAIN HR 510

- Milling head, ZF gearbox and drive spindle cooling via oil circulation

- Cooling of the Y-axis ball screw via oil circulation

- ZF Reducer gearbox cooled, 2-stage (1 - 1,000 / 1,001 - 4,000 rpm)

- Oil cooling system

- Linear Measuring System via HEIDENHAIN® Scales with DA 400 Compressed Air System

- SIEMENS / HEIDENHAIN Main spindle motor 28/38 KW

- AC Drives HEIDENHAIN

- Precision ball screws in all axes

- Rear chip conveyor

- Hydraulic weight compensation in the Z-axis

- Coolant system via nozzle ring, 8 bar with large-volume coolant tank

- Coolant quantity adjustable via potentiometer on the control panel

- With spindle cooling option 1 main tank and 1 pre-tank

- Automatic blow-out unit of the cone - Automatic milling heads

- Compressed air through nozzle ring via M-function

- Air through the spindle, max. 10 bar, controlled via M-function

- Automatic central lubrication

- Workspace cladding with partly multi-layer doors and windows according to CE

- Safety enclosure of the rear machine area according to CE

- RITTAL switch cabinet with RITTAL air conditioning

- Operating and working lights LED

To the overview of our bed type milling machines

https://www.volmatec.de/fraesmaschinen/bettfraesmaschinen.html

Translated with DeepL

KIHEUNG KNC U 1350 / 1500 BT

|

Universal bed type milling machine

VOLMATEC / KIHEUNG

Universal bed type milling machines

| mm | |

| mm | |

| mm |

Product video: Here along

The logical continuation of the successful, compact universal bed-type milling machines of the KIHEUNG KNC U - machine series are the ideal milling machines for a high chip volume and at the same time excellent geometrical manufacturing accuracy, equipped with the latest HEIDENHAIN TNC 640 CNC control.

Due to the wide flat guides and the innovative FLAT-Ram machine design, where all drive and transmission units, such as spindle motor, ZF gear or belt pulley are placed on the rear area of the boom, this KNC U series achieves a very good geometric accuracy in combination with an impressive milling performance.

- HEIDENHAIN TNC 640 contouring control with MC 7522 main computer including software option I

- Milling head, ZF gearbox and drive spindle cooling via oil circulation

- Cooling of the Y-axes ball screws via oil circulation

- Universal vertical milling head system HURON

- Chip conveyor rear

- Linear Measuring System via HEIDENHAIN Scales with DA 400 Compressed Air System

- SIEMENS / HEIDENHAIN Main spindle motor 28/38 KW

- AC Drives HEIDENHAIN

- ZF reduction gear cooled, 2-stage (1 - 1,000 / 1,001 - 4,000 rpm)

- hydraulic weight compensation in the Z-axis

- Spindle orientation for rigid tapping

- Preparation of the PLC for a 4th axis

- automatic blow-out unit of the cone - automatic milling heads

- Electronic portable handwheel HEIDENHAIN HR 410

- Compressed air through nozzle ring via M-function

- Air through the spindle, max. 10 bar, controlled via M-function

- automatic central lubrication

- Workspace cladding with partly multi-layer doors and windows according to CE

- Safety enclosure of the rear machine area via fence and sheet metal system with secured inspection openings

- Coolant system via nozzle ring, 8 bar with large-volume tank

- with option cooling by spindle 1 main tank and 1 pre-tank

- Preparation of the PLC for HEIDENHAIN TS 260 workpiece measuring system and for HEIDENHAIN TT 160 tool touch probe

- RITTAL switch cabinet with RITTAL air conditioning

- Operating and working light

- Tightening bolts, anchor bolts and pressure plates

- CE safety equipment

- Documentations

- Paint: Light grey RAL 7035, carmine red RAL 3002, slate grey RAL 7015

To the overview of our bed type milling machines

Translated with DeepL

KIHEUNG KNC U 1200 LT

|

Universal bed type milling machine

VOLMATEC / KIHEUNG

Universal bed type milling machines

| mm | |

| mm | |

| mm |

Product video: Here along

The linear guided universal bed type milling machines KNC LT are based on the successful KIHEUNG KNC machine series. The KIHEUNG KNC LT - machine series are the ideal milling machines for a high chip volume and at the same time excellent geometrical manufacturing accuracy, equipped with the latest HEIDENHAIN TNC 640 or SIEMENS 840 D sl CNC control.

Due to the innovative FLAT-Ram machine design, where all drive and transmission units, such as spindle motor, ZF-gearbox or belt pulley are placed on the rear area of the arm, the KNC U series achieves a geometrical accuracy that is almost unique in this machine class.

Equipment / Highlights

- HEIDENHAIN TNC 640 contouring control with MC 7522 main computer including software option I

- Milling head, ZF gearbox and drive spindle cooling via oil circulation

- Cooling of the Y-axes ball screws via oil circulation

- Universal vertical milling head system HURON

- Chip conveyor rear

- Linear Measuring System via HEIDENHAIN Scales with DA 400 Compressed Air System

- SIEMENS / HEIDENHAIN Main spindle motor 28/42 KW

- AC Drives HEIDENHAIN

- ZF reduction gear cooled, 2-stage (1 - 1,000 / 1,001 - 4,000 rpm)

- hydraulic weight compensation in the Z-axis

- Spindle orientation for rigid tapping

- Preparation of the PLC for a 4th axis

- automatic blow-out unit of the cone - automatic milling heads

- Electronic portable handwheel HEIDENHAIN HR 410

- Compressed air through nozzle ring via M-function

- Air through the spindle, max. 10 bar, controlled via M-function

- automatic central lubrication

- Workspace cladding with partly multi-layer doors and windows according to CE

- Safety enclosure of the rear machine area above

Fence and sheet metal system with secured inspection openings

- Coolant system via nozzle ring, 8 bar with large-volume tank

- with option cooling by spindle 1 main tank and 1 pre-tank

- Preparation of the PLC for HEIDENHAIN TS 260 workpiece measuring system and for HEIDENHAIN TT 160 tool touch probe

- RITTAL switch cabinet with RITTAL air conditioning

- Operating and working light

- Tightening bolts, anchor bolts and pressure plates

- CE safety equipment

- Documentations

- Paint: Light grey RAL 7035, carmine red RAL 3002, slate grey RAL 7015

To the overview of our bed type milling machines

Translated with DeepL

Circular table milling machines

Bettfräsmaschinen mit Rundtisch KIHEUNG RT - LT SerieDynamik-Line

|

Circular table milling machine

VOLMATEC / KIHEUNG

Circular table milling machines

| mm | |

| mm | |

| mm |

bed type milling machines with rotary table

KIHEUNG RT - LT Series - Dynamic Line

The new linear guided rotary table bed type milling machines of the KIHEUNG RT-LT series are the additions to our successful KIHEUNG RT series with longer travels in all axes and larger rotary tables.

Equipment / Highlights

- VOLMATEC remote diagnostics including HEIDENHAIN dongle

- Contouring control HEIDENHAIN TNC 640 or SIEMENS 840D

- Electronic portable handwheel HEIDENHAIN HR 510

- Stepless rotary table, pitch 0.001°, manufactured by OMR Italy or FIBRO Germany

- Milling head, ZF gearbox and drive spindle cooling via oil circulation

- Cooling of the Y-axis ball screw via oil circulation

- ZF Reducer gearbox cooled, 2-stage (1 - 1,000 / 1,001 - 4,000 rpm)

- Oil cooling system

- Linear Measuring System via HEIDENHAIN Scales with DA 400 Compressed Air System

- SIEMENS / HEIDENHAIN Main spindle motor 28/38 KW

- AC Drives HEIDENHAIN

- Precision ball screws in all axes

- INA RUE precision linear guidance systems in all 3-axes

- Rear chip conveyor

- Hydraulic weight compensation in the Z-axis

- Coolant system via nozzle ring, 8 bar with large-volume coolant tank

- Coolant quantity adjustable via potentiometer on the control panel

- With spindle cooling option 1 main tank and 1 pre-tank

- Automatic blow-out unit of the cone - Automatic milling heads

- Compressed air through nozzle ring via M-function

- Air through the spindle, max. 10 bar, controlled via M-function

- Automatic central lubrication

- Workspace cladding with partly multi-layer doors and windows according to CE

- Safety enclosure of the rear machine area according to CE

- RITTAL switch cabinet with RITTAL air conditioning

- Operating and working lights LED

bed type milling machines overview

Translated with DeepL

KIHEUNG RTW 1350 / 1500 LT - Dynamik-Line

|

Circular table milling machine

VOLMATEC / KIHEUNG

Circular table milling machines

| mm | |

| mm | |

| mm |

Large rotary table diameters and an additional movable column ensure precision machining of even large-radial milled parts.

Translated with DeepL

KIHEUNG RTW 1350 / 1500 - Force-Line

|

Circular table milling machine

VOLMATEC / KIHEUNG

Circular table milling machines

| mm | |

| mm | |

| mm |

Flat guided 5-axis bed-type milling machine for heavy-duty cutting of large workpieces in one clamping.

Translated with DeepL

Single column milling machines for long workpieces

KIHEUNG TRAX

|

Single column milling machine for long workpieces

VOLMATEC / KIHEUNG

Single column milling machines for long workpieces

| mm | |

| mm | |

| mm | |

| mm |

product video

The KIHEUNG TRAX are fast, linear guided travelling column milling machines and the ideal large milling machines, combined with a high chip volume and at the same time excellent geometrical manufacturing accuracy, when it comes to modular, future-proof expandability, e.g. with plate fields, rotary tables for pendulum machining.

Due to the dynamic linear guides and the innovative FLAT-Ram machine design, where all drive and transmission units, such as spindle motor, ZF-gearbox or belt pulley are placed on the rear area of the arm, the TRAX achieves a geometrical accuracy, high dynamics and still high chip removal rates that are almost unique in this machine class!

Equipment / Highlights

- HEIDENHAIN TNC 640 contouring control with MC 7522 main computer including software option I

- Milling head, ZF gearbox and drive spindle cooling via oil circulation

- Cooling of the Y-axes ball screws via oil circulation

- Universal vertical milling head system HURON for TRAX-U series

- Controlled sleeve for TRAX-H series

- Linear Measuring System via HEIDENHAIN Scales with DA 400 Compressed Air System

- SIEMENS® / HEIDENHAIN Main spindle motor 28/38 KW

- AC Drives HEIDENHAIN

- ZF reduction gear cooled, 2-stage (1 - 1,000 / 1,001 - 4,000 rpm)

- hydraulic weight compensation in the Z-axis

- Spindle orientation for rigid tapping

- Preparation of the PLC for a 4th axis

- automatic blow-out unit of the cone - automatic milling heads

- Electronic portable handwheel HEIDENHAIN HR 410

- Compressed air through nozzle ring via M-function

- Air through the spindle, max. 10 bar, controlled via M-function

- automatic central lubrication

- Workspace cladding with partly multi-layer doors and windows according to CE

- Safety enclosure of the rear machine area via fence and sheet metal system with secured inspection openings

- rear hinged chip conveyor with increased lateral discharge

- Coolant system via nozzle ring, 8 bar with large-volume tank

- with option cooling by spindle 1 main tank and 1 pre-tank

- Preparation of the PLC for HEIDENHAIN TS 260 workpiece measuring system and for HEIDENHAIN TT 160 tool touch probe

- RITTAL switch cabinet with RITTAL air conditioning

- Operating and working light

- Tightening bolts, anchor bolts and pressure plates

- CE safety equipment

- Documentations

- Paint: Light grey RAL 7035, carmine red RAL 3002, slate grey RAL 7015

Our travelling column milling machines

Translated with DeepL

KIHEUNG HiTRAX

|

Single column milling machine for long workpieces

VOLMATEC / KIHEUNG

Single column milling machines for long workpieces

| mm | |

| mm | |

| mm | |

| mm |

product video

These heavy milling machines are designed in a combination of flat guides and flat guide with roller shoe support. They are the big brothers of the TRAX machine series. These stable yet dynamic travelling column milling machines are the ideal travelling column milling machines for heavy-duty machining of large, heavy workpieces.

Due to this combination of flat and roller shoe guidance and the innovative FLAT-Ram machine design, where all drive and transmission units, such as spindle motor, ZF gearbox or pulley are placed on the rear area of the boom, the HiTRAX achieves a high geometric accuracy, high dynamics and very high chip removal rates in this machine class!

Equipment / Highlights

- HEIDENHAIN TNC 640 contouring control with MC main computer including software option I

- Milling head, ZF gearbox and drive spindle cooling via oil circulation

- Cooling of the Y-axes ball screws via oil circulation

- Universal vertical milling head system HURON for HiTRAX-U series

- Horizontal milling spindle 130 mm Ø, quill travel 700 mm for HiTRAX-H

- Full workspace cladding with partly multi-layer doors and windows according to CE

- Safety enclosure of the rear machine area via a metal wall enclosure and/or fence systems according to CE

- rear hinged chip conveyor with increased lateral discharge

- Flat guides, partly supported by roller shoes in all 3 axes

- Linear Measuring System via HEIDENHAIN® Scales with DA 400 Compressed Air System

- HEIDENHAIN® Main spindle motor 32/53 KW

- AC Drives SIEMENS® / HEIDENHAIN®

- ZF reduction gear cooled, 2-stage

- hydraulic weight compensation in the Z-axis

- Spindle orientation for rigid tapping

- Preparation of the PLC for a 4th axis

- automatic blow-out unit of the cone - automatic milling heads

- Electronic portable handwheel HEIDENHAIN® HR 410

- Compressed air through nozzle ring via M-function

- Air through the spindle, max. 10 bar, controlled via M-function

- automatic central lubrication

- Coolant system via nozzle ring, 8 bar with large-volume tank

- Preparation of the PLC for HEIDENHAIN® TS 260 workpiece measuring system and for HEIDENHAIN® TT 160 tool touch probe

- RITTAL® control cabinet with RITTAL® air conditioning

- Operating and working light

- Tightening bolts, anchor bolts and pressure plates

- CE safety equipment

- Documentations

- Paint: Light grey RAL 7035, carmine red RAL 3002, slate grey RAL 7015

Traveling column milling machines

KIHEUNG HiTRAX Series Force-Line

Translated with DeepL

KIHEUNG WiNGTRAX

|

Single column milling machine for long workpieces

VOLMATEC / KIHEUNG

Single column milling machines for long workpieces

| mm | |

| mm | |

| mm | |

| mm |

WINGTRAX

The WINGTRAX, the heavyweight of the KIHEUNG moving column machine series. These heavy travelling column milling machines are the ideal large travelling column milling machines for heavy machining of particularly large, heavy workpieces.

Thanks to this combination of flat and roller shoe guidance and the innovative FLAT-Ram machine design, where all drive and transmission units, such as spindle motor, ZF gearbox or belt pulley are placed on the rear area of the boom, the WINGTRAX achieves a high geometric accuracy and high dynamics at very high chip removal rates in this machine class!

All models of the WINGTRAX series, have large traverse paths - up to 20,000 mm in the X-axis and up to 6,500 mm in the Y-axis, extensive standard equipment and extensive options (e.g. infinitely variable automatic milling heads, tool changing systems, cooling through the spindle, chip conveyor systems and much more). With these possibilities the KIHEUNG milling machines can be adapted optimally to your present and future machining needs.

Equipment / Highlights

- HEIDENHAIN TNC 640 contouring control with MC 7522 main computer including software option I

- Milling head, ZF gearbox and drive spindle cooling via oil circulation

- Cooling of the Y-axes ball screws via oil circulation

- Universal vertical milling head system HURON for WiNGTRAX-U series

- Controlled sleeve for WiNGTRAX-H series

- Linear Measuring System via HEIDENHAIN Scales with Compressed Air System

DA 400

- SIEMENS main spindle motor 60/84 KW

- AC drives SIEMENS

- hydraulic weight compensation in the Z-axis

- Spindle orientation for rigid tapping

- Preparation of the PLC for a 4th axis

- automatic blow-out unit of the cone - automatic milling heads

- Electronic portable handwheel HEIDENHAIN HR 410

- Workspace cladding with partly multi-layered doors and windows

according to CE

- Safety enclosure of the rear machine area above

Fence and sheet metal system with secured inspection openings

- Coolant system via nozzle ring, 8 bar with large-volume tank

- with option cooling by spindle 1 main tank and 1 pre-tank

- Preparation of the PLC for HEIDENHAIN TS 260 workpiece measuring system and for HEIDENHAIN TT 160 tool touch probe

- RITTAL switch cabinet with RITTAL air conditioning

- Operating and working light

- Tightening bolts, anchor bolts and pressure plates

- CE safety equipment

- Documentations

- Lacquering: light grey RAL 7035, carmine red RAL 3002,

Slate grey RAL 7015

Our travelling column milling machines

Translated with DeepL

Universal knee-type milling machines

KIHEUNG D-TRAX Serie

|

Universal knee-type milling machine

VOLMATEC / KIHEUNG

Universal knee-type milling machines

| mm | |

| mm | |

| mm |

Starrbettfräsmaschinen ? KIHEUNG D-TRAX Serie Dynamik-Line

Die neuen KIHEUNG D-TRAX Starrbettfräsmaschinen mit Starrbett oder integriertem Rundtisch, ist das Beste aus zwei Welten ? die Robustheit einer Starrbettfräsmaschine mit hohen Tischbelastungen und der Dynamik einer lineargeführten Fräsmaschine und somit die logische Ergänzung zur kraftvollen, flachgeführten Starrbettfräsmaschine RiGiTRAX.

Das innovative Modulkonzept der D-TRAX Serie ermöglicht nun ungeahnte Möglichkeiten einer fortschrittlichen, modernen Zerspanung und Reserven für die Zukunft. Das angesprochen Modulkonzept ermöglicht, neben dem starren Gusstisch (Starrbett) mit hohen Tischbelastungen und einer Erweiterung mit integrierten Rundtischen, auch Vorrichtungen zur Pendelbearbeitung. Durch die erhöhte Stabilität durch Verbindung der Ständereinheit mit dem Maschinentisch gewährleistet die neuen D-TRAX Modellreihe höchste Präzision und Genauigkeiten bei gleichzeitig erhöhter Spanleistung.

Die dynamischen Linearführungen und das innovative 3-fach FLAT-Ram Maschinendesign, wo alle Antriebs- und Übertragungseinheiten, wie z.B. Spindelmotor, ZF Getriebe oder Riemenscheibe auf dem hinteren Bereich des Auslegers platziert werden, erreicht die D-TRAX eine in dieser Maschinenklasse fast einzigartige, geometrische Genauigkeit, hohe Dynamik bei dennoch hohen Spanleistungen!

Maschinenhighlights / Ausstattung:

? VOLMATEC Ferndiagnose inklusive HEIDENHAIN Dongle

? Bahnsteuerung HEIDENHAIN TNC 640 oder SIEMENS 840 D

? Elektronisches, tragbares Handrad HEIDENHAIN HR 510

? Fräskopf-, ZF Getriebe- und Antriebsspindelkühlung über Ölumlauf

? Kühlung der Y-Achsen Kugelrollspindel über Ölumlauf

? ZF Reduziergetriebe gekühlt, 2-stufig (1? 1.000/1.001 ? 4.000 U/min)

? Ölkühlsystem

? Linear-Messsystem über HEIDENHAIN Maßstäbe mit Druckluftsystem DA 400

? SIEMENS/ HEIDENHAIN Hauptspindelmotor 28/38 KW

? AC-Antriebe HEIDENHAIN

? Präzisions-Kugelumlaufspindeln Y- und Z-Achse

? Zahnstangenantrieb REDEX ? X-Achse

? INA RUE Präzisions-Linearführungen in allen Achsen

? Rückwärtiger Späneförderer

? Hydraulischer Gewichtsausgleich in der Z-Achse

? Kühlmitteleinrichtung über Düsenkranz, 8 bar mit großvolumigen

? Kü?hlmitteltank

? Kühlmittelmenge über Potentiometer am Bedienpult einstellbar

? Bei Option Kühlung durch die Spindel 1 Haupttank und 1 Vortank

? Automatische Ausblaseinheit des Kegels ? Automatik-Fräsköpfe

? Druckluft durch Düsenkranz über M-Funktion

? Luft durch die Spindel, max. 10 bar, gesteuert über M-Funktion

? Automatische Zentralschmierung

? Rückwärtiges Bedienpanel in Bedienkabine integriert

? Arbeitsraumverkleidung mit teils mehrlagigen Türen und Fenstern gemäß CE

? Sicherheitseinhausung des rückwärtigen Maschinenbereiches gemäß CE

? RITTAL Schaltschrank mit RITTAL Klimaanlage

? Bedien- und Arbeitsleuchten LED

KIHEUNG RiGiTRAX Serie

|

Universal knee-type milling machine

VOLMATEC / KIHEUNG

Universal knee-type milling machines

| mm | |

| mm | |

| mm |

Starrbettfräsmaschinen ? KIHEUNG RiGiTRAX Serie Force-Line

Die flachgeführten Starrbettfräsmaschinen KIHEUNG RiGiTRAX überzeugen durch ihr Maschinenkonzept ? das Beste aus Bettfräsmaschine und Fahrständerfräsmaschine in einer Maschine vereint.

Die RiGiTRAX Maschinenbaureihen sind die idealen Großfräsmaschinen für extreme Tischbelastungen (3.500 kg / m²), verbunden mit einem hohen Spanvolumen bei gleichzeitig exzellenter geometrischer Fertigungsgenauigkeit.

Durch die Kombination von dynamischen Linearführungen und "stabilen" Flachführungen erreicht die RiGiTRAX eine in dieser Maschinenklasse fast einzigartige Spanleistung bei hohen geometrischen Genauigkeiten. Auch hier ist der Ausleger im FLAT-Ram Design ausgeführt bei dem alle Antriebs- und Übertragungseinheiten, wie z.B. Spindelmotor, ZF Getriebe oder Riemenscheibe auf dem hinteren Bereich des Auslegers platziert werden.

Alle Modelle der RiGiTRAX-Baureihen, verfügen über große Verfahrwege ? X-Achse bis 10.000 mm, weitreichende Serienausstattung und umfangreiche Optionen (z.B. stufenlose Automatik-Fräskopfe, Werkzeugwechselsysteme, Kühlung durch die Spindel, Spänefördersysteme und vieles mehr)! Durch diese Möglichkeiten lassen sich die KIHEUNG Fräsmaschinen optimal an Ihre gegenwärtigen und zukünftigen Bearbeitungsbedürfnisse anpassen.

Maschinenhighlights/Ausstattung:

? VOLMATEC Ferndiagnose inklusive HEIDENHAIN Dongle

? Bahnsteuerung HEIDENHAIN TNC 640 oder SIEMENS 840D

? Elektronisches, tragbares Handrad HEIDENHAIN HR 510

? Fräskopf-, ZF Getriebe- und Antriebsspindelkühlung über Ölumlauf

? Kühlung der Y-Achsen Kugelrollspindel über Ölumlauf

? ZF Reduziergetriebe gekühlt, 2-stufig (1? 1.000/1.001 ? 4.000 U/min)

? Ölkühlsystem

? Linear-Messsystem über HEIDENHAIN Maßstäbe mit Druckluftsystem DA 400

? SIEMENS / HEIDENHAIN Hauptspindelmotor 28/38 KW

? AC-Antriebe HEIDENHAIN

? Doppel-Linearführung und Flach-Rollenführung in der X-Achse

? Flachführungen in der Y- und Z-Achse

? Präzisions-Kugelumlaufspindeln Y- und Z-Achse

? Zahnstangenantrieb REDEX ? X-Achse

? Rückwärtiger Späneförderer

? Hydraulischer Gewichtsausgleich in der Z-Achse

? Kühlmitteleinrichtung über Düsenkranz, 8 bar mit großvolumigen Kühlmitteltank

? Kühlmittelmenge über Potentiometer am Bedienpult einstellbar

? Bei Option Kühlung durch die Spindel 1 Haupttank und 1 Vortank

? Automatische Ausblaseinheit des Kegels ? Automatik-Fräsköpfe

? Druckluft durch Düsenkranz über M-Funktion

? Luft durch die Spindel, max. 10 bar, gesteuert über M-Funktion

? Automatische Zentralschmierung

? Rückwärtiges Bedienpanel in Bedienkabine integriert

? Arbeitsraumverkleidung mit teils mehrlagigen Türen und Fenstern gemäß CE

? Sicherheitseinhausung des rückwärtigen Maschinenbereiches gemäß CE

? RITTAL Schaltschrank mit RITTAL Klimaanlage

? Bedien- und Arbeitsleuchten LED

Portal milling machines

KIHEUNG SUPER-MiMAX

|

Portal milling machine

VOLMATEC / KIHEUNG

Portal milling machines

| mm | |

| mm | |

| mm | |

| mm |

Portal milling machines

KIHEUNG MiMAX-W SeriesMega-Line

Heavy portal milling machine with vertically movable cross beam for machining large-volume workpieces.

All models have large traverse paths in the X-axis and in the Y-axis, extensive standard equipment and extensive options (e.g. infinitely variable automatic milling heads, tool changing systems, cooling through the spindle, chip conveyor systems and much more). With these possibilities the KIHEUNG milling machines can be adapted optimally to your present and future machining needs.

- Large vertical working range due to a travel of the vertical arm of 1,000 mm and vertical travel of the cross slide of 2,200 mm.

- Workpiece weights up to 70 t.

- Elaborate, stable 4-sided guidance of the vertical boom for high milling performance with very good Z-axis geometry.

- 8-fold guidance of the vertical slide via precision-ground flat guide and corresponding wedge strips. In combination with high torques, very good cutting performance is guaranteed.

- Machine available in various configurations and special sizes.

Equipment / Highlight

- CNC contouring control HEIDENHAIN TNC 640

- Linear Measuring System via HEIDENHAIN® Scales

- vertical milling spindle 3,000 rpm

- Double chip conveyor system on both sides of the bed

- AC Drives HEIDENHAIN

- Spindle oil cooler

- SIEMENS / HEIDENHAIN Main spindle motor 31/60 KW

- Hydraulic weight compensation in the Z-axis

- Spindle orientation for rigid tapping

- Coolant system via nozzle ring, 8 bar with large-volume tank system

- Electronic portable handwheel HEIDENHAIN HR 410

- Ethernet interface

- RITTAL switch cabinet with RITTAL air conditioning

Portal milling machines

KIHEUNG MiMAX-W SeriesMega-Line

Translated with DeepL