E. Zoller

Products

Software for production and production planning

Software for stock and materials management

TMS Tool Management Solutions

|

Software for stock and materials management

E. ZOLLER GmbH & Co. KG

Software for stock and materials management

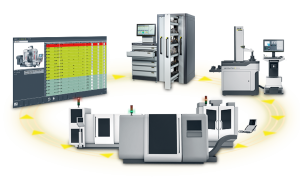

The three software packages BRONZE, SILVER and GOLD offer everything that is needed in a manufacturing process. Modular in design, expandable as required – and easy to implement. ZOLLER TMS Tool Management Solutions grow with your requirements step by step. Start with the BRONZE package and make your tool management significantly more economical. Convinced? Then continue with the warehouse management and the SILVER package. Because efficient warehouse management saves money. And you have full cost control with the GOLD package and perfect tool organization. At ZOLLER, growing along also means that our packages always remain up-to-date: Functionalities are expanded and we respond to new requirements with new functions that become standards for us, integrated into our updates. So that you will always have the latest version available in the future. ZOLLER TMS Tool Management Solutions can easily integrate all relevant third-party systems, from ERP and CAM systems to cabinet and lift systems and machines. Tool identification systems by means of chip or data matrix code and the orientation towards future requirements with regard to Industry 4.0 are also already a reality at ZOLLER today. Only ZOLLER offers this: The overall performance with TMS Tool Management Solutions PLUS a ZOLLER setting and measuring device, services, interfaces to programming systems and much more. This powerful combination is your big PLUS: for a consistent process solution – from the simple tooling system to the transmission of actual data to the machine control. Translated with DeepL

Software for manufacturing process simulation

Schnittstelle ZOLLER - ESPRIT

|

Software for manufacturing process simulation

E. ZOLLER GmbH & Co. KG

Software for manufacturing process simulation

DP Technology is one of the leading manufacturers and suppliers of Computer-Aided-Manufacturing (CAM) software for a wide range of manufacturing industries. ESPRIT, DP Technology's flagship product, is a high-performance, high-quality NC programming system for milling, drilling, turning, wire EDM, and multifunction machines such as mill-turn centers. The easy and intuitive ESPRIT CAM interface to the ZOLLER TMS Tool Management Solutions enables the simple exchange of tool data.

Translated with DeepL

CAM software

Schnittstelle ZOLLER - hyperMILL®

|

CAM software

E. ZOLLER GmbH & Co. KG

CAM software

OPEN MIND Technologies AG develops and sells innovative CAM/CAD solutions that generate optimal NC milling and turning programs for machine tools on the basis of digital models. Manufacturers from a wide range of industries around the world choose OPEN MIND products because they enable them to produce economically and efficiently. This enables them to create models, prototypes, tools, molds, prismatic workpieces, integral components and more in impressive quality. The hyperMILL interface to the ZOLLER TMS Tool Management Solutions gives you convenient access to the extensive ZOLLER database.

Translated with DeepL

Tool management software

»flash« Tool-Monitoring

|

Tool management software

E. ZOLLER GmbH & Co. KG

Tool management software

For Optimum Capacity Utilization of Your Tool Potential

The production analysis software »flash« ensures the optimum potential capacity utilization of the tool: communication with the CNC machine, allows the live tool status query and thus ensures a timely tool change. The respective current remaining tool lives are queried at the machine and their status displayed in traffic-light colors. Tool use can therefore be organized optimally.

Procedure in Four Steps

The status is recorded first — tools, the warning limits of which are reached or whose tool life has even expired (1), are selected and recommended for recommissioning. As soon as the tool has been completely commissioned and fitted (2), it is present, measured (3) and then released for production (4).

How Does This Benefit You?

Minimum waiting time at the machine, efficient production workflow, optimum tool utilization – maximum productivity below the line in respect of tool lives with simultaneous process safety.