OTEGO’s Expertise in Technical Fabrics for Bellows

OTEGO’s Expertise in Technical Fabrics for Bellows

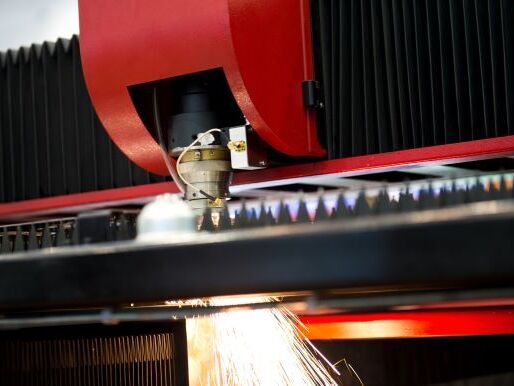

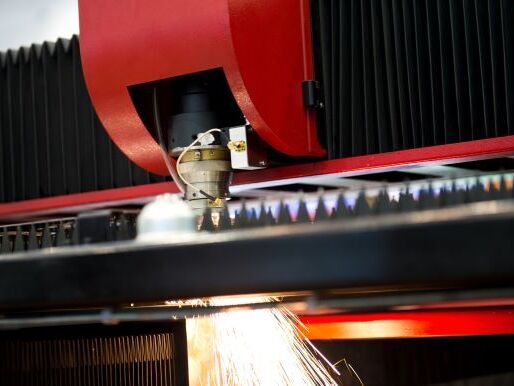

With decades of expertise in technical textiles, OTEGO supplies a range of specialized fabrics designed for bellow cover manufacturers worldwide. Our materials deliver reliable protection in environments with constant particle projection (abrasive scraps or powders), heavy oil exposure, and high-temperature conditions. They stand up to cutting oils, water splashes, and high-speed spatters, keeping machinery protected and operational.

Key Performance Features of OTEGO Bellow Fabrics

· Heat Resistance: Reliably perform in environments up to 150°C.

· Chip Impact Resistance: Withstand impacts from sharp-edged particles and debris.

· Chemical Resistance: Proven to resist various chemicals including ASTM1, SKYDROL, MEC, and alcohol.

· Waterproof: Guard against liquids/coolants with a waterproof rating up to 0.7 bars.

· PFAS-free & safe in use: No volatile toxic gas emissions under thermal stress

Applications for OTEGO Fabrics in Industrial Environments

Our fabrics are highly recommended for large-size bellow covers and specialized applications such as semiconductors, PCB/PWB production, and quartz processing or grinding machines. They perform exceptionally in environments with cutting oil and water splashes.

Benefits for Bellow Manufacturers

OTEGO fabrics offer practical advantages that simplify manufacturing and improve end-user reliability:

• Excellent folding memory ensures bellows retain shape over repeated cycles.

• Strong weldability on PVC plates supports easier fabrication and assembly.

• Extended durability reduces replacement frequency and downtime.

• Lower total cost of ownership (TCO) through longer service life and fewer interruptions.

Come Hall 6, Booth H02 and discover fabrics that bring reliability, durability, and sustainability to machine protection!

OTEGO’s Expertise in Technical Fabrics for Bellows

With decades of expertise in technical textiles, OTEGO supplies a range of specialized fabrics designed for bellow cover manufacturers worldwide. Our materials deliver reliable protection in environments with constant particle projection (abrasive scraps or powders), heavy oil exposure, and high-temperature conditions. They stand up to cutting oils, water splashes, and high-speed spatters, keeping machinery protected and operational.

Key Performance Features of OTEGO Bellow Fabrics

· Heat Resistance: Reliably perform in environments up to 150°C.

· Chip Impact Resistance: Withstand impacts from sharp-edged particles and debris.

· Chemical Resistance: Proven to resist various chemicals including ASTM1, SKYDROL, MEC, and alcohol.

· Waterproof: Guard against liquids/coolants with a waterproof rating up to 0.7 bars.

· PFAS-free & safe in use: No volatile toxic gas emissions under thermal stress

Applications for OTEGO Fabrics in Industrial Environments

Our fabrics are highly recommended for large-size bellow covers and specialized applications such as semiconductors, PCB/PWB production, and quartz processing or grinding machines. They perform exceptionally in environments with cutting oil and water splashes.

Benefits for Bellow Manufacturers

OTEGO fabrics offer practical advantages that simplify manufacturing and improve end-user reliability:

• Excellent folding memory ensures bellows retain shape over repeated cycles.

• Strong weldability on PVC plates supports easier fabrication and assembly.

• Extended durability reduces replacement frequency and downtime.

• Lower total cost of ownership (TCO) through longer service life and fewer interruptions.

Come Hall 6, Booth H02 and discover fabrics that bring reliability, durability, and sustainability to machine protection!