BLM Group at BLECHEXPO 2017

The BLM GROUP will participate at BLECHEXPO (November 7-10, 2017), the classic machine tool event held every two years in Stuttgart, Germany. The systems displayed in Stand 1610 of Hall 1 showcase some key concepts which will characterise the manufacturing world of the future and outline the fourth industrial revolution as seen by BLM GROUP.

Stuttgart, November 7, 2017. The catchphrase, “Future Is Calling” recently used during the INTUBE XXVII Open House, is as strong as ever and is an invitation to step into the future as leading players, not spectators. The BLM GROUP is interpreting Industry 4.0 as the change which will affect the entire manufacturing world, characterised by innovative concepts and above all, practicality.

From the machine to the process

Change your point of view! For the BLM GROUP, manufacturing is viewed as a single process rather than a series of disconnected and independent steps. The focus has shifted from the single job to the finished part – in other words, from the machine to the product. Software is playing a key role in this process. For example, the Artube CAD-CAM system can be used to import a 3D model of the finished product, identify and break down the single laser cutting and bending jobs to allocate them into the various manufacturing systems. Programmers can intervene if they wish, but they are no longer forced to design each job one-by-one by analysing what happened before and trying to predict what will happen after. All this is done for them by the system.

Integration

This is a key concept of Industry 4.0. Simply designing with the final product in mind is not enough; the various steps of the manufacturing process must be integrated. The machines must dialogue with the manufacturing management system to make the entire process effective and to obtain the best results in the shortest possible time. Only the BLM GROUP can suggest something like this, with its range of complete systems for tube processing and its specialized technical know-how in the specific technologies. The applications within the ProTube Enterprise package are effective and practical tools for managing and controlling a complete manufacturing process in which the machines dialogue and collaborate with one another.

Simplification

System operation must be simple and user-friendly. Simplifying human-machine interaction means increasing work safety and efficiency. The new graphic interface which characterise the systems on display must concretely and fully describe this unstoppable trend, but there is more:

simplification also and above all passes through intelligent transfer within production systems. More evolved functions that can make crucial decisions for the correct job result and for final product quality, now provide essential help to operators so that they can work more reliably, effectively and efficiently. Laser “Active Tools”, B_Tools and B_Right for bending systems are just some of the examples of decision-making transferred from the operator to the machine.

The future is calling us through these BLM GROUP systems on display at BLECHEXPO:

- LC5: the combined tube and sheet system, the best example of laser processing flexibility and automation with a 6kW fibre laser source.

- 10 Fibre: the most flexible and complete lasertube system of all. Simple to use with new graphic interface and Active Tools functions.

- E-TURN 40: the tube bender which automatically detects errors with the B-RIGHT system and interacts with upstream and downstream systems to obtain parts in tolerance at the first attempt.

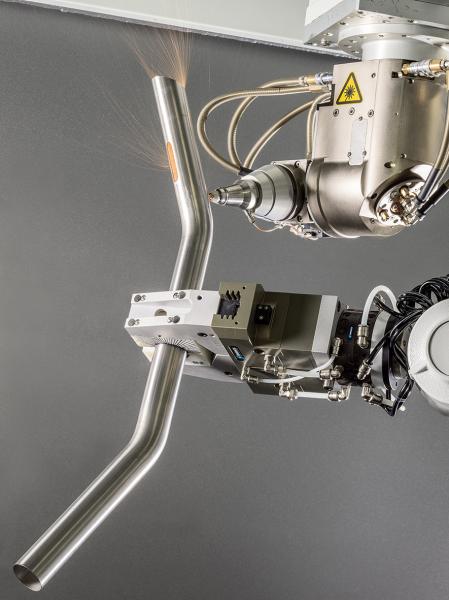

- LT-FREE: the 5-axis laser system for processing sheets, boxed sections, drawn materials and tubes with unmatched flexibility.

“Future Is Calling” is an invitation to everyone. Small workshops will experience automation and interconnection solutions, building sound foundations for future development. Larger companies will find automatic manufacturing systems capable of connecting and easily interfacing with each other and the manufacturing management systems.

For more information:

Giovanni Zacco – Communication BLM GROUP

E-mail: [email protected]

Tel.: +39 031 7070200

BLM GROUP

BLM GROUP is a global partners for the entire tube-manufacturing process. It is found throughout the world and offers thousands of applications:

- BLM S.p.A., based in Cantù (CO), specialised in the production of CNC tube-bending machines, measuring units and the relative supplementary and automating devices.

- ADIGE S.p.A. based in Levico Terme (TN) manufactures systems for laser-cutting tubes and machines for disc-cutting tubes, solids and sections. The range is completed by brushing machines, measuring systems, washing systems and collectors

- ADIGE-SYS S.p.A. based in Levico Terme (TN) specialises in the production of "mixed" laser-cutting systems for cutting tubes and sheet metal, plant for laser-processing of large-sized tubes and end cutting and removing lines for tubes and bars.

www.blmgroup.com

www.inspiredfortube.com

Facebook: http://www.facebook.com/BLMGROUP

Twitter: http://twitter.com/blmgroup

YouTube: http://www.youtube.com/BLMGROUPchannel

Google+: http://google.com/+Blmgroup

Italy

Italy