BLM GROUP

Products

Tube bending machines

4-RUNNER

|

Tube bending machine

BLM GROUP

Tube bending machines

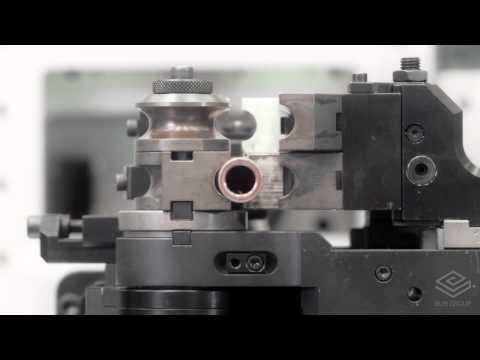

4-RUNNER is a complete production process starting from a coil: straightening, end-forming (up to six passes), facing, rolling, bending, cutting and controlled unloading of the finished part all in one.

The unquestionable advantage of this combined machining centre is that it can be configured and used with various modules for specific jobs or complete processes from straightening to unloading the finished parts entirely cut, bent and formed.

On bending side, the 4-RUNNER allows to make fixed and variable radius arrangements on the plane and in space, which can be integrated according to design development in automatic sequences without bending problems: all-in-one process, without reworks.

The possibility of combining multiple radius bending or stretching technologies on the same part guarantees the best flexibility and the highest production rates.

On end-forming side, the machine may be configured with four or six push passes or four push and one revolving pass.

Different cutting devices are used according to applications: inner orbital cutter, outer orbital cutter, disc cutter.

Extreme versatility like this means:

• top flexibility for jobs and applications

• top efficiency and low investments costs with integrated processes and the possibility of implementing just-in-time methods

• 3D visual graphic programming (VGP3D) makes using the machine extremely easy, comfortable and safe.

The 4-RUNNER bending centre is particularly suited to machining small and medium size tubes even of very complex shapes typically used in automotive, air conditioning, heating or cooling system applications.

E-TURN

|

Tube bending machine

BLM GROUP

Tube bending machines

Fully electric bending machine, with right and left bending in process and 3D graphic visual programming (VGP3D)

Some features of E-TURN fully electric machine:

• No mechanical adjustment is needed

• In-process right and left bending, with fixed and variable radius

• Reduced time for programming and change-over

• Enhanced controllability and repeatability

• Increased productivity (by even 20% compared to hydro-electric machines)

• Widest flexibility, thanks to the reduced dimension of the bending head and of the free bending and variable radius positioning

• Increased feasibility of more complex structures

• Tool holders designed for the fully interchangeability with existing BLM machines

• Integrated machine load and load

The machine is programmed by the programming and 3D simulation software BLM VGP3D which allows:

• component feasibility can be checked without physically testing on the machine or making prototype tooling

• pre-production calculation of the real cycle time is known, so production costs and component pricing can be more precise

• by simply inputting the components bend coordinates, the complete bending program is graphically simulated

Machine available in three versions:

ET32 - maximum tube O.D. capacity from 6 to 32x2mm

ET35 - maximum tube O.D. capacity from 6 to 35x2mm

ET40 - maximum tube O.D. capacity from 6 to 40x2mm

ET52 - maximum tube O.D. capacity from 6 to 52x2mm

ELECT

|

Tube bending machine

BLM GROUP

Tube bending machines

Fully electric CNC tube bender for tubes with OD 80 mm, 9 axis with 3D visual graphic programming (VGP3D)

Features:

• multiradii (up to 8 tools)

• bend head with left or right hand bending sense configuration

• all the critical machine setting parameters set and managed by the CNC control

• Fixed, variable radius and boost bend up to 5.000 kg

• High reliability and high productivity

• Use of existing tools - low running costs

• Real time bend simulation automatically selecting the shortest and most efficient bending cycle to minimize cycle time and reduce cost

• Any possible collision points are highlighted and the most practical avoidance routes effected

• Axis position is read by absolute encoder eliminating all conventional sensors, increasing reliability, performance and reducing maintenance cost

VGP3D Highly innovative 3D Graphic Programming Software dramatically reducing dependence on operator intervention for:

• real time bend simulation automatically selecting the shortest and most efficient bending cycle to minimise cycle time and reduce cost

• component simulation and feasibility check highlighting any possible collisions

• immediate creation and execution of the machine program with twin data input

The multi-stack tool mounting facility allows multi radius and variable radius bending to the same tube in a single set up, bends with very little straight between them, even compound bends. Generally used within the automotive and climate control sectors.

SMART

|

Tube bending machine

BLM GROUP

Tube bending machines

SMART is the new all-electric (8 axes) tube bending machine with 3D visual programming software ( VGP3D), SMART meets the following requirements:

• Can be freely and quickly switched into right-hand or left-hand configuration

• Multi-stack

• The automatic load and unload integrated in the machine offer the possibility of lights-out operation

• Compact machine with small footprint (compact layout)

Suitable for the bending of tubes up to diam. 28 mm, SMART offers the following advantages:

• Fixed or variable radius bending

• All critical machine setting parameters are fixed and managed by the CNC (clamping, pressure die, mandrel, CLR)

• Set-up data are stored together with the piece program

• Constant repeatability and accuracy

• Cheaply to run (power consumption reduced up to 50% compared to electro-hydraulic machines)

• Environment friendly: no oil disposal, noise level < 70dba

• Reduced capital expenditure

• Easy to use

Programming is made through the BLM graphical interactive programming software VGP3D, with:

• Component feasibility check and generation of themost suitable working cycle (times and costs)

• Likely collision risks are highlighted and the most efficient avoidance route selected automatically

• by simply inputting the components bend coordinates, the complete bending program is graphically simulated

Particularly suitable for the bending of tubes with complex shape and multiple bending radii, even pre-assembled (fittings, end-forms, etc.), mostly used in the automotive branch (hydraulic pipes, air conditioning, power supply) as well as HVAC.