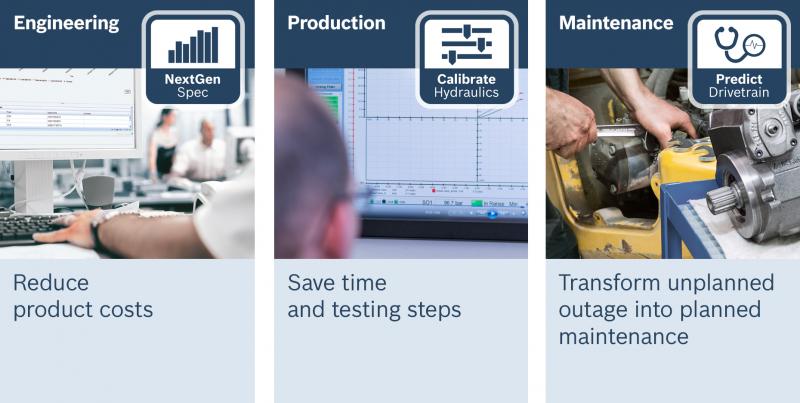

As part of the electronification of mobile hydraulics, Bosch Rexroth is developing new, data-based services for all aspects of rail vehicles. The PredictDrivetrain service from Bosch Rexroth detects wear using operating and sensor data and is able to determine the remaining service life. Thus, downtimes for rail vehicles in the field can be avoided without the conventional, pre-scheduled preventive maintenance intervals. The lean determination of operating data also serves as a basis for the application-oriented design of mechanical components using the NextGenSpec app without the danger of undersizing or oversizing. For the assembly of new vehicles, CalibrateHydraulics significantly reduces the commissioning effort with the online transfer of test bench data for components to the OEM.

Until now, the maintenance of rail vehicles has essentially happened at fixed intervals, whereby the service engineer replaces components regardless of their state or visually inspects them on the outside. In doing so, however, they are not able to detect the internal degree of wear. As a result, expensive failure happens again and again to mobile working machines in the field, even though the maintenance intervals were adhered to and numerous components were replaced, some of them unnecessarily.

That's why Bosch Rexroth offers the PredictDrivetrain app, a data-based service which recognizes wear on components and modules before a failure occurs. Sensors for rotational speed, pressure and temperature of the pump and motor, which are already largely integrated into the hydraulic systems of the mobile working machines, capture the operating conditions. Software links this data with big data analysis instruments and Bosch Rexroth's knowledge of components. From this it reliably detects anomalies and gradually developing defects. The PredictDrivetrain app prepares this information automatically and warns a defined group of people of impending machine failure. OEMs can integrate PredictDrivetrain into their own software architecture.

Real data from multi-axis accelerometers in one or several vehicles serves to continuously improve mechanical components, such as the transmission and the chassis. The NextGenSpec app from Bosch Rexroth captures the mechanical loads while the machine is in operation and generates detailed cloud-based diagrams of load data. R&D departments can then derive the actual requirements for daily work. They can thus prevent undersizing or oversizing when specifying the components in the development phase of the next generation of the vehicle.

Bosch Rexroth offers a further new service with CalibrateHydraulics. This transmits individual test bench data for hydraulic pumps, motors and valves from Rexroth's final assembly to the assembly line of the vehicle manufacturers. This simplifies the necessary calibration of travel drives and implement hydraulics at the appropriate stations. As a result, manufacturers can partially, or even completely, automate calibration process steps which, until now, had to be carried out manually and tediously. This reduces production costs and ensures quality.

An Internet of Things (IoT) solution manages the transfer, processing and visualization of measured data for PredictDrivetrain and NextGenSpec. Bosch Rexroth exclusively uses open interfaces to integrate the apps into existing systems of various manufacturers. In addition, Bosch Rexroth offers all-in-one solutions from a single source in cooperation with other divisions in the corporate group. These consist of telematics units from Bosch, the Bosch IoT Cloud and software solutions from the Bosch IoT Suite.

Germany

Germany