Citizen Machinery

Products

Turning machines (lathes)

Multi-spindle bar automatics

Cincom L20E-2M12

|

Multi-spindle bar automatic

Citizen Machinery Europe GmbH

Multi-spindle bar automatics

A machine synonymous with the history of Cincom has been redesigned for the new age with 3 models in modular design. Ranging from a 5-axis machine with excellent cost performance to a high-end machine equipped with B axis and a back spindle Y axis, you may select the machine according to the functions you require. The machine concept offers unrivalled versatility - various gang tool posts, drilling holders for front and back machining with and without rotary tools are available from which the customer may select the types best suited for his requirements at hand.

Cincom A20-3F7N

|

Multi-spindle bar automatic

Citizen Machinery Europe GmbH

Multi-spindle bar automatics

Acclaimed for its excellent cost to performance ratio, the A20 has evolved as a 5-axis machine for 20 mm diameter applications with the advantage that it can be used with or without a guide bush. It can be used as a regular guide bush automatic lathe when machining long slender workpieces, and without a guide bush for shorter parts with minimal bar remnants. The guide bush can be quickly and simply mounted and removed.

The performance of the machine has been improved too. The high-speed 10,000 rpm spindle enables optimized machining operations on smaller-diameter bar material. The machining length per chucking is now extended to 200 mm enabling the number of re-chuckings and thus the cycle times to be reduced when machining long workpieces. As an option, bar material of up to Ø 25 mm can also be machined extending the range of workpieces even more.

Cincom D25-1M7

|

Multi-spindle bar automatic

Citizen Machinery Europe GmbH

Multi-spindle bar automatics

The D25 sliding head automatic lathe inspires by its high motor capacity and its large variance of workpieces. It is perfectly suited for fast and complex machining processes. The innovative control unit has been designed in accordance with state-of-the-art standards and is easy to operate.

Equipped with double gang tool post and one B axis (type VIII), the D25 sliding headstock type automatic lathe features extremely short machining times hand in hand with maximum productivity.

The high number of workpieces of the main and back spindle keeps production cost low and offers versatile machining options ? everything on a single machine. As an option, bar material of up to Ø 25 mm can also be machined extending the range of workpieces even more.

Cincom D25-1M8

|

Multi-spindle bar automatic

Citizen Machinery Europe GmbH

Multi-spindle bar automatics

The D25 sliding head automatic lathe inspires by its high motor capacity and its large variance of workpieces. It is perfectly suited for fast and complex machining processes. The innovative control unit has been designed in accordance with state-of-the-art standards and is easy to operate.

Equipped with double gang tool post and one B axis (type VIII), the D25 sliding headstock type automatic lathe features extremely short machining times hand in hand with maximum productivity.

The high number of workpieces of the main and back spindle keeps production cost low and offers versatile machining options ? everything on a single machine. As an option, bar material of up to Ø 25 mm can also be machined extending the range of workpieces even more.

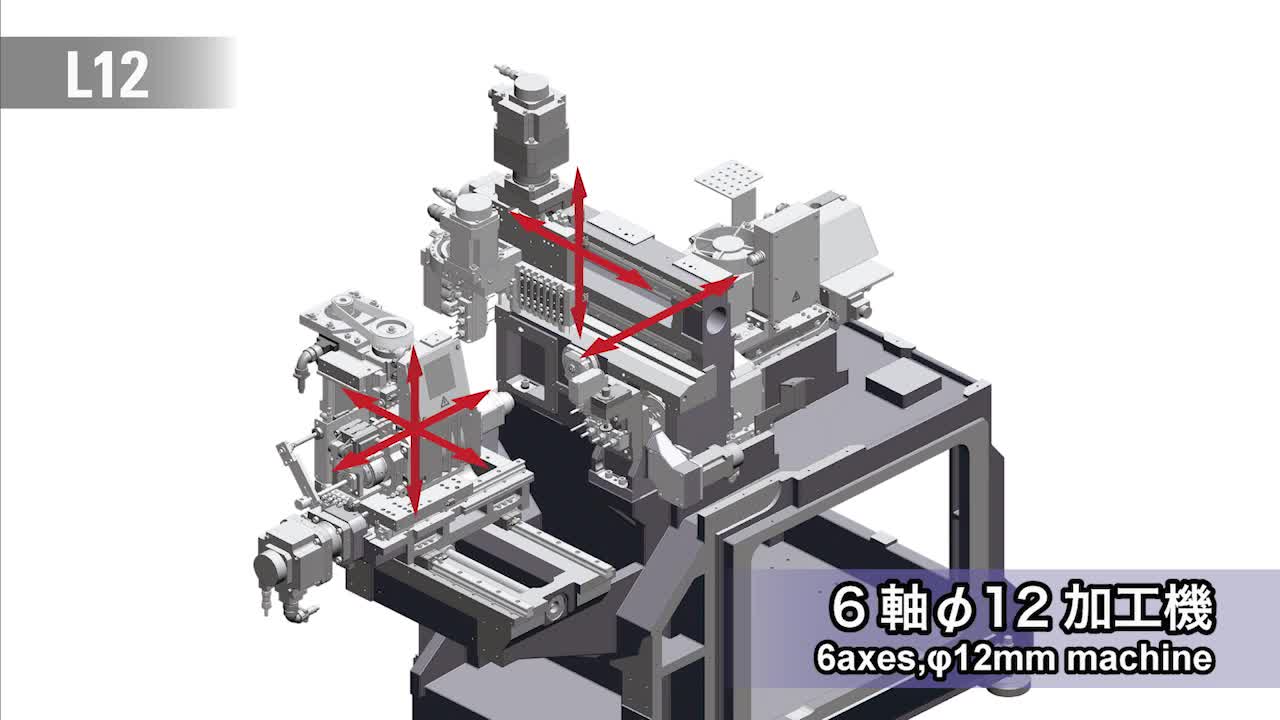

Cincom L12-1M7

|

Multi-spindle bar automatic

Citizen Machinery Europe GmbH

Multi-spindle bar automatics

It is a simple matter to fit or remove the guide bushing so that the machine configuration can be adapted to suit the workpiece to be machined.

As an automatic lathe that combines two roles in a single unit, it can be used to machine both long and short workpieces effectively. It also shows uncompromising performance as a machine for high-speed, small- diameter applications. It shortens cycle times with a front spindle capable of high-speed rotation of 15,000 rpm and 10,000 rpm rotary tools. The L series that has built Cincom?s history is now creating the new ?standard? in automatic lathes for function and performance.

Cincom L12-2M10

|

Multi-spindle bar automatic

Citizen Machinery Europe GmbH

Multi-spindle bar automatics

It is a simple matter to fit or remove the guide bushing so that the machine configuration can be adapted to suit the workpiece to be machined.

As an automatic lathe that combines two roles in a single unit, it can be used to machine both long and short workpieces effectively. It also shows uncompromising performance as a machine for high-speed, small- diameter applications. It shortens cycle times with a front spindle capable of high-speed rotation of 15,000 rpm and 10,000 rpm rotary tools. The L series that has built Cincom?s history is now creating the new ?standard? in automatic lathes for function and performance.

Cincom L20E-2M8

|

Multi-spindle bar automatic

Citizen Machinery Europe GmbH

Multi-spindle bar automatics

A machine synonymous with the history of Cincom has been redesigned for the new age with 3 models in modular design. Ranging from a 5-axis machine with excellent cost performance to a high-end machine equipped with B axis and a back spindle Y axis, you may select the machine according to the functions you require. The machine concept offers unrivalled versatility - various gang tool posts, drilling holders for front and back machining with and without rotary tools are available from which the customer may select the types best suited for his requirements at hand.

Cincom L20E-2M10

|

Multi-spindle bar automatic

Citizen Machinery Europe GmbH

Multi-spindle bar automatics

A machine synonymous with the history of Cincom has been redesigned for the new age with 3 models in modular design. Ranging from a 5-axis machine with excellent cost performance to a high-end machine equipped with B axis and a back spindle Y axis, you may select the machine according to the functions you require. The machine concept offers unrivalled versatility - various gang tool posts, drilling holders for front and back machining with and without rotary tools are available from which the customer may select the types best suited for his requirements at hand.

Cincom M16-4M5

|

Multi-spindle bar automatic

Citizen Machinery Europe GmbH

Multi-spindle bar automatics

The M16 type VIII features a B axis for rotary tools on the gang tool post. It can machine angled holes and complete shapes. The swivel angle of the B axis is 135° and it can be used in both front and back machining. The back tool post is equipped with a Y axis (type VIII) and up to 9 tools can be carried. But we have not just upped the number of controlled axes and the number of mountable tools.

In addition to upping the rapid feed rate to 32 m/min and running high-speed calculation with the latest NC unit, the maximum rotational speeds of the front/back spindle and the rotary tools on the turret tool post have also been increased.

By machining with the optimum conditions for small-diameter workpieces and small-diameter drills/end mills, high productivity can be achieved.

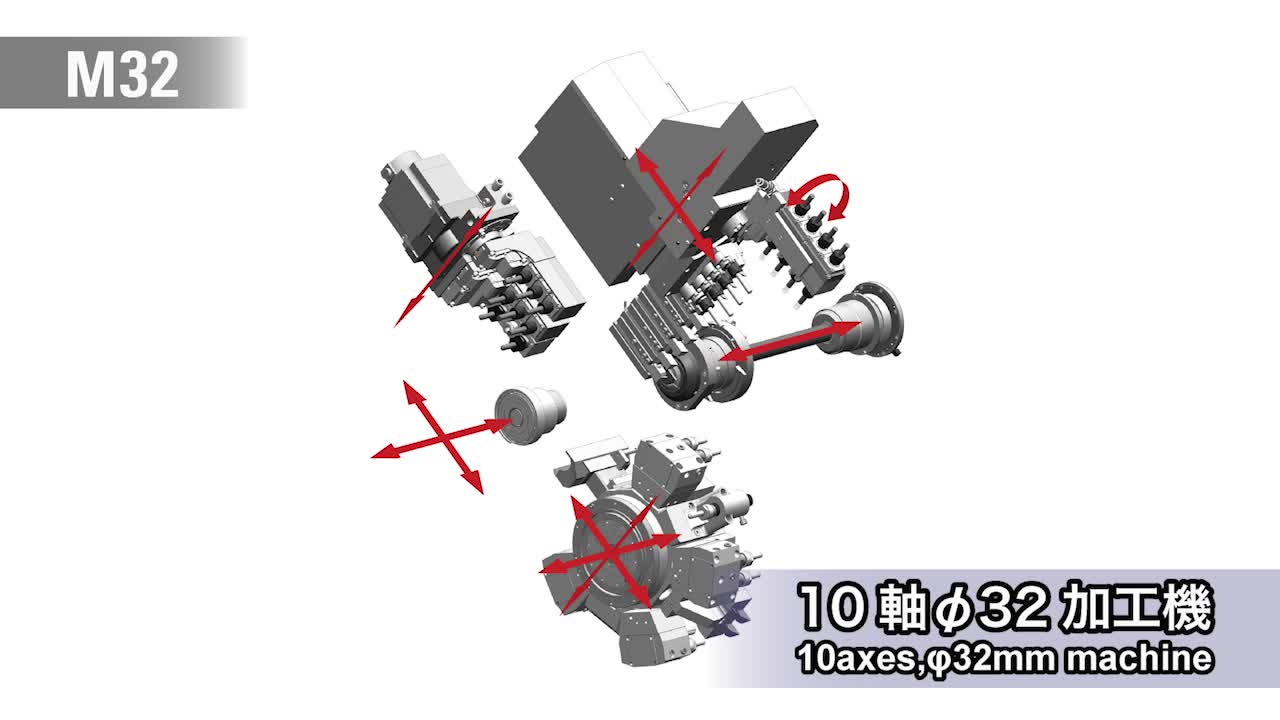

Cincom M32-4M5

|

Multi-spindle bar automatic

Citizen Machinery Europe GmbH

Multi-spindle bar automatics

Adoption of newly designed cover to provide workability, as well as a new HMI operating panel for the new NC unit and touch panel provides improved operability and productivity. Additionally, structural analysis was performed to achieve a highly rigid design that provides an optimal balance between strength and weight at small footprint to greatly improve the rigidity required during machining. The turret tooling has been completely redesigned with a conversion to single-drive for rotary tools and strengthening of the rotary tools motor.

The gang tool post has been equipped with a type VIII B-axis spindle for contouring by use of five- axis control.

The back tool post has been equipped with adjustable-angle type VII and VIII spindles to provide complex machining in combination with the Y axis. Improved back machining improves the degree of freedom in machining process allocation. A 5.5/7.5 kW high-output spindle motor has been adopted for main and back spindles. You can switch between use and non-use of guide bushes for compatibility with 38-mm oversize specifications.

Cincom M32-5M5

|

Multi-spindle bar automatic

Citizen Machinery Europe GmbH

Multi-spindle bar automatics

Adoption of newly designed cover to provide workability, as well as a new HMI operating panel for the new NC unit and touch panel provides improved operability and productivity. Additionally, structural analysis was performed to achieve a highly rigid design that provides an optimal balance between strength and weight at small footprint to greatly improve the rigidity required during machining. The turret tooling has been completely redesigned with a conversion to single-drive for rotary tools and strengthening of the rotary tools motor.

The gang tool post has been equipped with a type VIII B-axis spindle for contouring by use of five- axis control.

The back tool post has been equipped with adjustable-angle type VII and VIII spindles to provide complex machining in combination with the Y axis. Improved back machining improves the degree of freedom in machining process allocation. A 5.5/7.5 kW high-output spindle motor has been adopted for main and back spindles. You can switch between use and non-use of guide bushes for compatibility with 38-mm oversize specifications.

Cincom R5 04-6

|

Multi-spindle bar automatic

Citizen Machinery Europe GmbH

Multi-spindle bar automatics

For machining watch parts, probe/connector pins, medical parts and other ultra-small-diameter components, we have completely revised the machine design - in pursuit of ''the ideal machine'' with ''true-ease-of-use''. A 20,000 rpm spindle achieves the optimum cutting speed for the workpiece. This in combination with a tool post integrated with the guide bushing mount to suppress thermal displacement and feed axis drives combining linear and servo motors help to maximise accuracy, compactness and low energy consumption.

Cincom?s solution for machining ultra-small-diameter parts is here.

Universal automatic lathes

Cincom B12E-VI

|

universal automatic lathe

Citizen Machinery Europe GmbH

Universal automatic lathes

The B series, which has sold well worldwide for a long time, has been revamped. The B16 can handle diameters up to 16 mm, so the range of target workpieces has been expanded. The B series is renowned for its speed, accuracy and high reliability at extremely low running cost. This 4th generation model retains the same tool layout granting high-accuracy machining in the proven manner.

The rigidity of the back headstock has been improved. Preprocessing for shortest cycle time is supported by a simple on-machine program check function.

The standard specifications include a comprehensive range of NC functions.

Cincom B16E-VI

|

Universal automatic lathe

Citizen Machinery Europe GmbH

Universal automatic lathes

The B series, which has sold well worldwide for a long time, has been revamped with a significant price revision. The B16E can handle diameters up to ?16 mm, so the range of target workpieces has been expanded. The B series is renowned for it?s speed, accuracy and high reliability at extremely low running cost. This 4th generation model retains the same tool layout which that brings high-accuracy machining. The rigidity of the back headstock has been improved. Preprocessing, for shortest cycle time is supported by an on-machine program check function for easy proveout. The standard specifications include a comprehensive range of NC functions.

Miyano ABX-51SYY2

|

universal automatic lathe

Citizen Machinery Europe GmbH

Universal automatic lathes

The ABX-51/64SYY features shortened cutting times by simultaneous machining at left and right with two Y axes. The ability to machine simultaneously at the left and right spindles using the upper and lower turrets, both featuring a Y-axis function, means that complete front and back machining of products with complex shapes can be accomplished simply and in a short time.

Miyano BNA-42CY5

|

universal automatic lathe

Citizen Machinery Europe GmbH

Universal automatic lathes

Type SY with improved performance as a bar-material processing machine.

Type CY may also be used as a chucker machine.

Miyano BNA-42DHY3

|

Universal automatic lathe

Citizen Machinery Europe GmbH

Universal automatic lathes

The BNA-DHY distinguishes itself by a compact structure and numerous high-performance and accuracy features as well as 2 turrets and one Y-axis. All features for which Miyano has rightly been renowned by our demanding customers. This makes the BNA-DHY an extremely flexible machine.

Miyano BNA-42GTY

|

universal automatic lathe

Citizen Machinery Europe GmbH

Universal automatic lathes

Hand scraped slideways offering maximum stability and rigidity are used to achieve the renowned ''Miyano accuracy''. These slideways excel at extraordinarily high rigidity as well as excellent damping characteristics thus contributing to powerful machining and extended tool life. The main components of the machine, like spindles and tool slides, are installed on the stable cast bed. The machine is designed in a way that mounting faces are not distorted by the effects of heat. Even if the units are subject to thermal expansion, they are all displaced in the same direction (perpendicular to their mounting faces). This minimizes relative deviations between the workpice and cutting tools.

Miyano BNA-42MSY2

|

universal automatic lathe

Citizen Machinery Europe GmbH

Universal automatic lathes

We proudly introduce: Model BNA-42MSY - CNC turning center with 2 spindles and 1 turret. The turret features a Y axis and half-indexing, expanding the machining possibilities. The machine is equipped with the largest spindle motor in the series, enabling powerful cutting.

The X2 axis at the back spindle allows for the simultaneous machining at the front and back of the workpiece. This model combines the advantages of a double turret machine and the lower purchase price of a machine with just one turret. The unique control improves productivity and cycle times.

Miyano BND-51SY2

|

universal automatic lathe

Citizen Machinery Europe GmbH

Universal automatic lathes

The BND bar machine is equipped with a back spindle an a Y-axis that can machine bar material up to Ø 51 mm. The structure of the machine offers precision scraped square slideways that provide the high rigidity and excellent vibration damping characteristics and a heavy 30° slanted bed as platform construction with intelligently arranged ribs ensuring good thermal stability and minimum dimensional changes over time. In other words: A comprehensive package designed for consistently high machining accuracy over long operating periods.

Miyano BNE-51MSY

|

universal automatic lathe

Citizen Machinery Europe GmbH

Universal automatic lathes

The BNE series is renowned for its high rigidity, heavy cutting capability and outstanding precision. The MSY model extends the ability of the BNE series with the adoption of X3 axis on the back spindle (SP2) and synchronized / superimposed control for 3-tool simultaneous machining. Faster cycle times, outstanding easy-of-use and the ability to machine complex work pieces is the result.

Miyano BNE-51S6

|

universal automatic lathe

Citizen Machinery Europe GmbH

Universal automatic lathes

The BNE series has especially been designed for today's ever more demanding production of complex high-precision workpieces from bar stock. Thanks to multi-tool simultaneous machining, also more complex shapes may be machined now in an ultrafast and economical way. On type ''S'', multiple tools may simultaneously be mounted in L & R spindle. Type ''SY'' with Y axis slide for the upper turret offers functions similar to a machining center and efficiently machines complex workpieces.

Miyano BNJ-51SY6

|

universal automatic lathe

Citizen Machinery Europe GmbH

Universal automatic lathes

Turret No. 2 now has 8 tool mounting stations instead of 6 on the previous machines, so the number of tools has been increased and also rotary tools may be mounted. The milling processes that were handled using turret No. 1 alone can now be shared with turret No. 2, making it possible so substantially shorten cycle times and deal with workpieces that require complex machining.

Miyano GN-3200

|

universal automatic lathe

Citizen Machinery Europe GmbH

Universal automatic lathes

Designed for high-througput machining of small diameter workpieces, this machine has a wing type fixed spindle for low thermal influence and maximum thermal stability installed on a thermally symmetrical machine base. It inherits the ''design concept for high precision'' that is a tradition at Ocean series.

The slideways grant excellent damping characteristics and are finally precision scraped by experienced experts. Based on these constructive properties, the user receives a complete package designed for excellent machining accuracy in terms of dimensional stability and concentricity. The workpieces can of course be handled manually, but the machine also flexibly accommodates automation including high-speed gantry loaders and robots. This makes high-precision machining even more efficient.

Loading ...