For users of machine tools, maximum possible flexibility is without doubt the most efficient answer to constantly growing market requirements. This is particularly true for the production of small batches of different workpiece variants, because the more flexibility a machine has to offer, the lower the corresponding life cycle costs are to be evaluated. Werkzeugmaschinenbau Ziegenhain, or WMZ for short, specializes in the development and construction of custom machines for the complete and combined machining of shaft-shaped components. Depending on the requirement, thread-cutting and deburring work as well as gear cutting using the power skiving or hobbing techniques can be integrated in the WMZ complete machining cycle alongside turning, drilling, grinding and milling techniques.

Increasing cost pressure combined with shorter achievement times and the demand for ever greater manufacturing depth presents both small and large production companies with new challenges. To be able to survive on the market, investments in new machine tools must be particularly future-proof and flexible. WMZ, a member of the DVS TECHNOLOGY GROUP, offers a wide range of production methods which can be combined for use in one machine thanks to the modular design for the horizontal machining of shaft-shaped components with a length of up to 4500 mm. The resulting combined or complete machining of components leads to significant cost reductions for various reasons.

For one thing, a major share of the retooling, transport and storage times is no longer required, which leads to a significant reduction in overall machining time. For another, the risk of reclamping faults is almost zero, since the component can ideally be made in one single clamping. In addition, the complete machining center has a smaller footprint, which, together with the lower purchasing costs, cuts the capital commitment of the investing company.

Complete machining – save costs

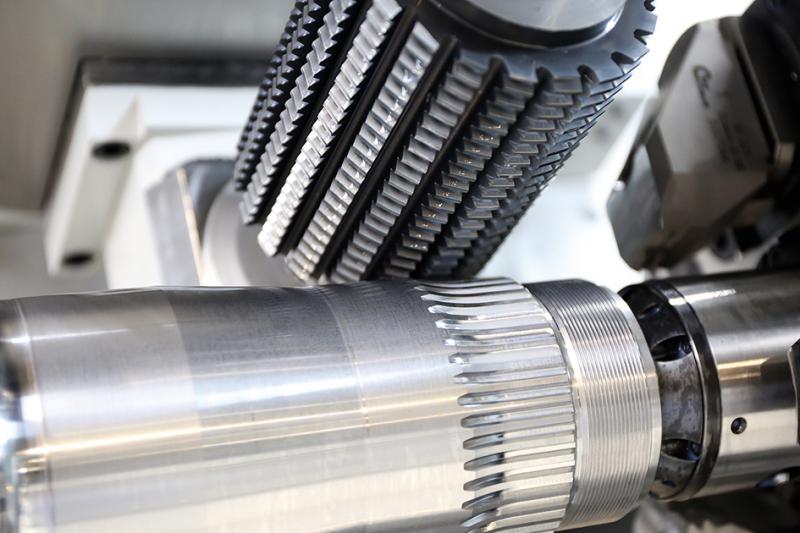

An example: With the machine platform H200 from WMZ, highly efficient turning and gearing work can be done on both ends of a shaft-shaped component by one turning turret and one hobbing unit each. With this example, there is no need to think about how the gearing will be deburred, because the lathes deal with this. By machining the external contour together with the gearing in one clamping, maximum concentricity of the gearing is achieved. Thus a hobbing or skiving unit can product gearing up to module 7 and quality 6. The milling units on the WMZ machines are equipped with a shift axis to achieve the longest possible service lives. This allows the hobbing tool to be used across the entire width without excessive wear. Tool changing should take as little time as possible, which is why the milling cutter holder is equipped with a quick-change system. The time required for hobbing alone can be more than halved by using milling tools with multiple threads.

Power skiving is economical for internal gearing

Hobbing is not suitable for components which require internal gearing or have an obstacle contour. WMZ machines mainly use the power skiving method for cutting gears in such circumstances. The power skiving technology has to measure up to alternative technologies such as broaching or shaping for the requirements mentioned. Gear shaping proves inadequate, since the technology, which is generally used for machining smaller batch sizes, involves inefficiently long machining times due to the discontinual process.

Broaching of the gearing is extremely inflexible, because gearing parameters such as the two-ball dimension and thus the quality of the gearing can be exclusively influenced by the geometry of the broach. In addition, broaching tools are very expensive to buy. In contrast, the tool costs for WMZ machines with power skiving module are within reasonable limits, since, thanks to a pivoting unit, a low-cost roughing tool can be used first for the coarse machining. The subsequent precise machining, which guarantees high gearing quality, is then performed by a high-precision dressing tool.

In order to avoid high tool costs for power skiving, the parallel tool concept used on the machines from the associated company PITTLER T&S has proved itself more than once. Good enough reason for the tool concept to be transferred to WMZ machines alongside the gearing technology within the context of constant exchange of technology within the companies of the DVS TECHNOLOGY GROUP.

Germany

Germany