We Drive Future Mobility

Turning machines (lathes)

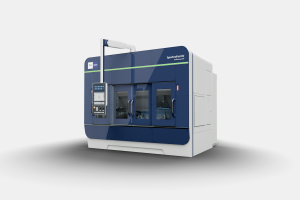

Universal automatic lathes

|

Multi-technology machine configurations are possible thanks to the modular system of the PV series. Complete machining of rotary components for diameters from 350–5,000 mm.

The machine series is available as a single-spindle machine with two separate work areas, each with a tool carrier, or as a pendulum slide machine to achieve the best possible balance between non-productive and productive times.

The machine program is designed to enable all possible uses on the machine, i.e., turning, grinding, drilling, and milling. The machine can also be fitted with a Y-axis in order to be able to realize genuine PITTLER SKIVING.

Find out more about the machine’s high level of flexibility and equipment variance.Highlights:

01

Up to 6-axis machining: turning, grinding, milling, drilling, measuring, PITTLER Skiving possible with Y-axis

02

Automatic tool changeover with up to 150 tools

03

High level of flexibility and equipment variance

04

Generously dimensioned work area and good accessibility for optimal loadability

Vertical turning machines

|

| Workspace |

|

| 450 mm | |

| 280 mm | |

Highlights:

01

Parallel and turning machining

02

Flexible workpiece feed from the rear of the machine into the automation room

03

Loading via storage table for up to 45 minutes of standalone processing

04

Automatic part separation – no defined placing of the raw and finished parts necessary

05

NC lift-off holder for brake disc machining

Precision lathes

|

| Workspace |

|

| 280 mm | |

| 80 mm | |

Highlights:

01

Parallel and turning machining

02

Flexible workpiece feed from the rear of the machine into the automation room

03

Loading via storage table for up to 45 minutes of standalone processing

04

Automatic part separation – no defined placing of the raw and finished parts necessary

05

NC lift-off holder for brake disc machining

Horizontal turning centres

|

|

| Workspace |

|

| 300 mm | |

| 1500 mm | |

Highlights:

01

Turning, milling and gear cutting of shafts in only one set-up

02

Simultaneous machining of both shaft ends thanks to center drive technology

03

6-sided machining in main and counter spindle with up to four tool carriers

04

Automatic tool change in 7 seconds due to disc magazine

05

Integrated automation for fast workpiece change

Universal automatic lathes

|

| Workspace |

|

| 4000 mm | |

| 1000 mm | |

The PV machines for machining large workpieces from 2,000 to 4,000 mm in diameter and 1,000 mm in height have a particularly stable machine bed with continuous support of the guide carrier for maximum rigidity and accuracy. Up to two cross slides can be installed on the guides of the machine bed, which can accommodate a wide range of tool carriers - from fixed tool holders to multifunction heads with B-axis and motorized milling spindle. Tool magazines can be provided for automatic tool change.

The solid headstock features a very robust and highly precise roller bearing. It is driven by a gear stage and is scalable by the number of motors installed. If required, two headstocks can also be used on one machine bed.

01

Powerful headstocks: S1 torques up to 72,000 Nm and S1 powers up to 300 kW. Infeeds up to 20 mm at 1 mm feed.

02

Technology toolbox consisting of tool carrier for turning, drilling, milling, gear cutting, grinding and B-axis for complex geometries

03

Automatic mold change via plate and chain magazines with up to 87 places

04

Solid machine bed with continuous guide beam support for maximum rigidity and accuracy

Universal lathes

|

| Workspace |

|

| 4000 mm | |

| 1000 mm | |

The PV machines for machining large workpieces from 2,000 to 4,000 mm in diameter and 1,000 mm in height have a particularly stable machine bed with continuous support of the guide carrier for maximum rigidity and accuracy. Up to two cross slides can be installed on the guides of the machine bed, which can accommodate a wide range of tool carriers - from fixed tool holders to multifunction heads with B-axis and motorized milling spindle. Tool magazines can be provided for automatic tool change.

The solid headstock features a very robust and highly precise roller bearing. It is driven by a gear stage and is scalable by the number of motors installed. If required, two headstocks can also be used on one machine bed.

01

Powerful headstocks: S1 torques up to 72,000 Nm and S1 powers up to 300 kW. Infeeds up to 20 mm at 1 mm feed.

02

Technology toolbox consisting of tool carrier for turning, drilling, milling, gear cutting, grinding and B-axis for complex geometries

03

Automatic mold change via plate and chain magazines with up to 87 places

04

Solid machine bed with continuous guide beam support for maximum rigidity and accuracy

Vertical turning machines

|

| Workspace |

|

| 4000 mm | |

| 1000 mm | |

The PV machines for machining large workpieces from 2,000 to 4,000 mm in diameter and 1,000 mm in height have a particularly stable machine bed with continuous support of the guide carrier for maximum rigidity and accuracy. Up to two cross slides can be installed on the guides of the machine bed, which can accommodate a wide range of tool carriers - from fixed tool holders to multifunction heads with B-axis and motorized milling spindle. Tool magazines can be provided for automatic tool change.

The solid headstock features a very robust and highly precise roller bearing. It is driven by a gear stage and is scalable by the number of motors installed. If required, two headstocks can also be used on one machine bed.

01

Powerful headstocks: S1 torques up to 72,000 Nm and S1 powers up to 300 kW. Infeeds up to 20 mm at 1 mm feed.

02

Technology toolbox consisting of tool carrier for turning, drilling, milling, gear cutting, grinding and B-axis for complex geometries

03

Automatic mold change via plate and chain magazines with up to 87 places

04

Solid machine bed with continuous guide beam support for maximum rigidity and accuracy

Other lathes

|