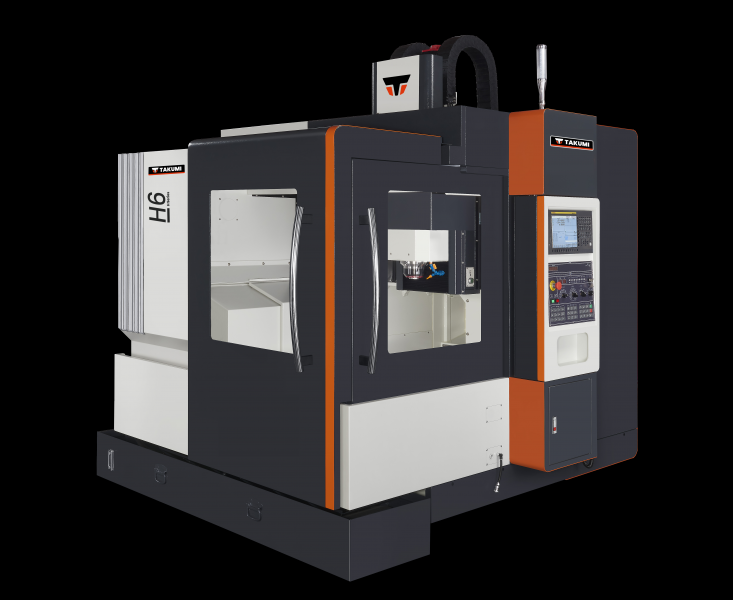

TAKUMI, manufacturer of ultra-precise, universal-use machining centers focusing on mold and die production, has now upgraded its entire machine fleet with an array of innovations and improvements.

The model fleet consists of the V and VC Series 3-axis machining centers, the H and BC Series 3-axis bridge-type machining centers, and the 5-axis machining centers from the U, UB and UC Series, along with the G Series graphite machining centers. Now it is possible to adapt each model in this fleet to its specific application environment with more precision than ever before. The machine sizes have undergone revision to more closely reflect precise operating requirements ─ as exemplified by the new H 6, featuring fast-turning spindles for dynamic production of small parts.

Components hailing from European production sites

Meanwhile, users can reap the rewards of multiple detailed improvements in both standard and optional equipment versions. In the 3-axis sector, the new BC Series lets customers select from a variety of spindles and replaceable drill heads such as the angled drill head for lateral machining tasks. Customers can also access an extensive inventory of optional fully-integrated 5-axis drill heads for even easier machine configuration using modular components. The wide array of milling head and spindle types as well as the various power ratings are complemented by HSK63, HSK100, SK and BT chuck assemblies. And these are always components from European production, which equates with precision and reliability. This also applies to linear and roller guide plate assemblies that continue to ensure precision when the going gets rough. All component activities are coordinated by Heidenhain control systems, which also manage the manufacturer's drive systems and linear scales.

Loading from the front, the side and above

Not least among the upgrade's assets are substantial improvements in the areas of access and serviceability: The centers can be loaded and unloaded from both the front and the side, while portal machines also allow these operations to be performed from above. The service points afford convenient access to facilitate maintenance. In the Takumi range, a robust and intrinsically stiff, high-precision structure assumes priority, while high levels of mechanical cushioning and thermal stability are additional assets. At which both rough machining operations and finishing processes produce impressive surface quality. The standard versions already incorporate extensive machining potential to provide a superb price-performance ratio

Germany

Germany