engineering to the point.

262

FollowersManufacturerisel Germany GmbH

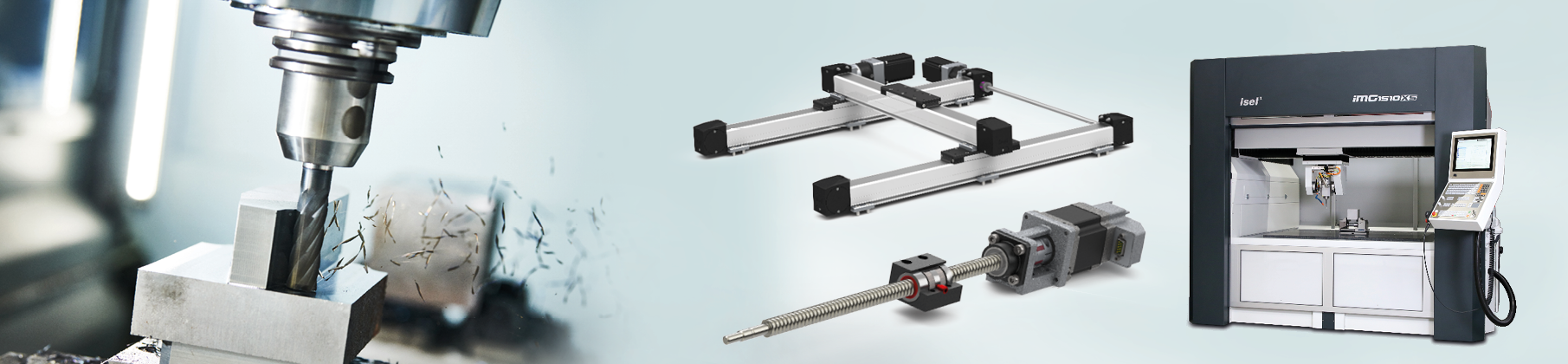

Product group Five-axis milling machining centres

Product NameIMG 1510 X5

Technical Data

Travel

Maximum X - axis travel1000 mm

Maximum Y-axis travel1000 mm

Maximum Z-axis travel350 mm

Machine control

Control optionsHeidenhain

Product images

Description

5 Axis Simultaneous Milling Machine for Wet and Dry Machining

The metal/granite sandwich construction für the moving axes such as gantry and crosshead can be driven by linear motors. It forms, in connection with high-precision linear guides, the

basis of the solid steel/granite machine construction. The advantages of natural stone granite in combination with high-strength light metal offer maximum rigidity and at the same time weight savings.

This is the only way to achieve the desired dynamics and high feed rates. The milling spindles used are high-frequency spindles with 1.5 KW, 2.0 KW or 4.0 KW and 40000 or 50000 rpm with HSK25 mounting.

The 10-station tool changer installed outside the working area automatically moves from the protective housing to the milling spindle. With the 4th/5th axis as a fork head version and the integrated high-precision gearbox drive modules, it is possible to reach almost all positions of a complex workpiece with the milling tool.

The machine is rounded off with new state-of-the-art CNC control functions and an easy-to-use user interface. These allow 5-axis simultaneous machining üvia RTCP – function (Rotation Tool Center Point). The control and operating components from Heidenhain include a touchscreen monitor and a convenient hand control. Different workholding systems can be applied to the universal granite table – via steel threaded bushings in a 150x150 mm grid, or a T-slot plate can be used.

Available in 5 different sizesü&aerospace;

iMG1010X5, iMG1510X5, iMG2010X5, iMG2015X5

Features:

OPTIONS:

FIELDS OF APPLICATION:

Für versatile application possibilities, we offer different workpiece clamping systems, which can be attached to the universal granite table via steel threaded bushings in a grid of 150x150 mm. Alternatively, a T-slot plate can also be used.

The machine is also equipped with state-of-the-art CNC control functions and features a userfriendly interface that enables 5-axis simultaneous machining via RTCP – function (Rotation Tool Center Point). Heidenhain's control and operating components include a touchscreen monitor and a convenient handheld control.

PLEASED MATERIALS:

- New steel/granite sandwich construction .

- 18-position tool change HSK-E25 expandable on request .

- HF spindle up to 4.0 kW and up to 45,000 rpm

- Optional encoder for thread cutting .

- Tool measurement/control

- 3D edge finder (radio)

- Minimum quantity lubrication

The metal/granite sandwich construction für the moving axes such as gantry and crosshead can be driven by linear motors. It forms, in connection with high-precision linear guides, the

basis of the solid steel/granite machine construction. The advantages of natural stone granite in combination with high-strength light metal offer maximum rigidity and at the same time weight savings.

This is the only way to achieve the desired dynamics and high feed rates. The milling spindles used are high-frequency spindles with 1.5 KW, 2.0 KW or 4.0 KW and 40000 or 50000 rpm with HSK25 mounting.

The 10-station tool changer installed outside the working area automatically moves from the protective housing to the milling spindle. With the 4th/5th axis as a fork head version and the integrated high-precision gearbox drive modules, it is possible to reach almost all positions of a complex workpiece with the milling tool.

The machine is rounded off with new state-of-the-art CNC control functions and an easy-to-use user interface. These allow 5-axis simultaneous machining üvia RTCP – function (Rotation Tool Center Point). The control and operating components from Heidenhain include a touchscreen monitor and a convenient hand control. Different workholding systems can be applied to the universal granite table – via steel threaded bushings in a 150x150 mm grid, or a T-slot plate can be used.

Available in 5 different sizesü&aerospace;

iMG1010X5, iMG1510X5, iMG2010X5, iMG2015X5

Features:

- Metal/granite sandwich construction .

- Twist-pivot cable head (4th And 5th axis)

- High dynamic linear motors in X and Y – axes .

- 18-cavity tool changer expandable to 36 tools .

- Heidenhain® TNC640 high-end control

- Tool measurement by toolsetter or laser

- 3D edge finder

- Handwheel

- Modern control panel

OPTIONS:

- Water cooling

- Heidenhain LMT TT160 / optional laser measurement

- 3D probe

- Handwheel

- Minimum quantity cooling

- Tool holders

FIELDS OF APPLICATION:

Für versatile application possibilities, we offer different workpiece clamping systems, which can be attached to the universal granite table via steel threaded bushings in a grid of 150x150 mm. Alternatively, a T-slot plate can also be used.

The machine is also equipped with state-of-the-art CNC control functions and features a userfriendly interface that enables 5-axis simultaneous machining via RTCP – function (Rotation Tool Center Point). Heidenhain's control and operating components include a touchscreen monitor and a convenient handheld control.

PLEASED MATERIALS:

- Precious metals for jewelry making .

- Stainless steel

- tempered steel

- Graphite

- ceramics

- Plastics such as PMMA/composite

- Copper

- Steel

- Titanium

- Special materials

- Medical technology

- Fine mechanics

- Micromachining

- Molding and prototyping

- Dental technology

- Jewelry industry

{{ this.trans('product.manufacturer') }} {{ $parent.product.manufacturer }}

{{ this.trans('product.product_group') }} {{ $parent.product.producttype }} | {{ $parent.product.category.title }} {{ $parent.product.category.title }}

{{ this.trans('product.itemnumber') }} {{ $parent.product.itemnumber }}

{{ this.trans('product.techdata') }}

{{ key }}

{{ key }} {{ value }}

{{ this.trans('product.techinfo') }}

{{ key }} {{ value }}

Description

Product images