engineering to the point.

261

FollowersManufacturerisel Germany GmbH

Product group Five-axis milling machining centres

Product NamePREMIUM 5030 GRUNDMASCHINE MIT 5 ACHSEN

Technical Data

Travel

Maximum X - axis travel500 mm

Maximum Y-axis travel350 mm

Maximum Z-axis travel176 mm

Machine control

Control optionsHeidenhain

Technical Info

Dimensions (W x D x H) mm

Type mm

Travel ranges mm

Table clamping surface WxD mm

Weight kg

Traversing speeds m/min

Milling spindles U/min

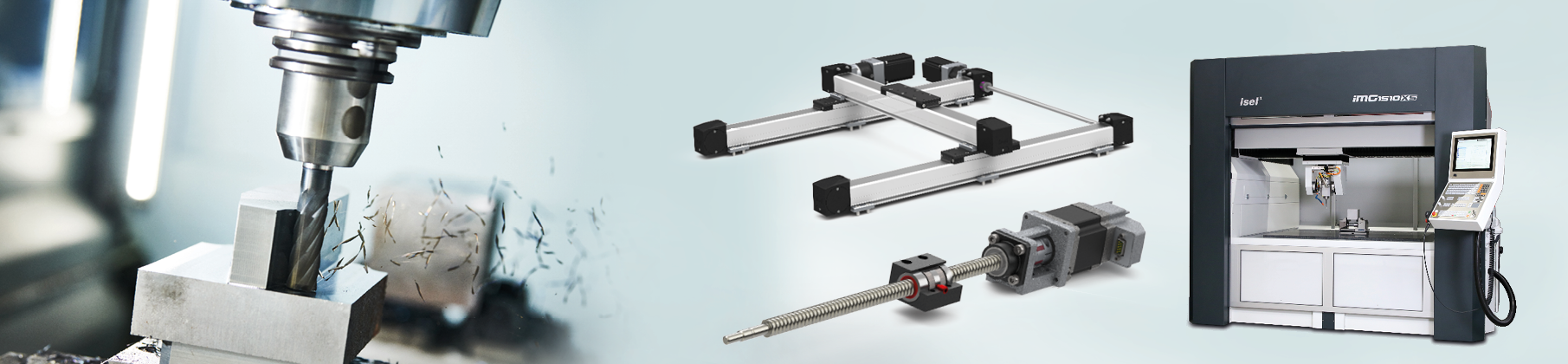

Product images

Description

GRANITE, STEEL AND LINEAR MOTORS FOR HIGHEST QUALITY MACHINING! The PREMIUM 5030 CNC milling machine is a 3- to 5-axis HSC milling system specifically designed to meet the requirements of high-precision machining of small precision mechanical parts, micromachining and milling of graphite/copper electrodes. In order to meet this demand for precision, all essential points for process-reliable manufacturing have been integrated into the CNC milling machine concept. The solid milling machine base, consisting of a natural hard stone granite gantry with decoupled Y-axis, guarantees high rigidity and long-term stability. The individual granite elements are manufactured to DIN876 / grade 00 accuracy. The pioneering linear motor technology and the incremental measuring method guarantee highest positioning accuracies at highly dynamic feed rates. The fastest control technologies (high-speed cutting) ensure harmonious path movements with simultaneous precision. In addition, the easy-to-operate user guidance under Windows® with i-8000 control is convincing. The highlights of the 5-axis PREMIUM 5030: CONSTRUCTION Solid and stable milling machine design made of ground granite components Small footprint due to compact design CONTROL HSC control technology with a block processing time < 1 ms in real time Control software under Windows® for i-8000 ZERO POINT CLAMPING SYSTEM Zero point clamping system in the granite table for fast changeover from 3-axes to 5-axes SPINDLE High frequency spindle with 50,000 rpm / 2 kW MOTOR Low maintenance linear motors in X,Y,Z ACCURACY High path accuracy due to digital length measuring system High load linear guides Translated with DeepL

{{ this.trans('product.manufacturer') }} {{ $parent.product.manufacturer }}

{{ this.trans('product.product_group') }} {{ $parent.product.producttype }} | {{ $parent.product.category.title }} {{ $parent.product.category.title }}

{{ this.trans('product.itemnumber') }} {{ $parent.product.itemnumber }}

{{ this.trans('product.techdata') }}

{{ key }}

{{ key }} {{ value }}

{{ this.trans('product.techinfo') }}

{{ key }} {{ value }}

Description

Product images