engineering to the point.

261

FollowersManufacturerisel Germany GmbH

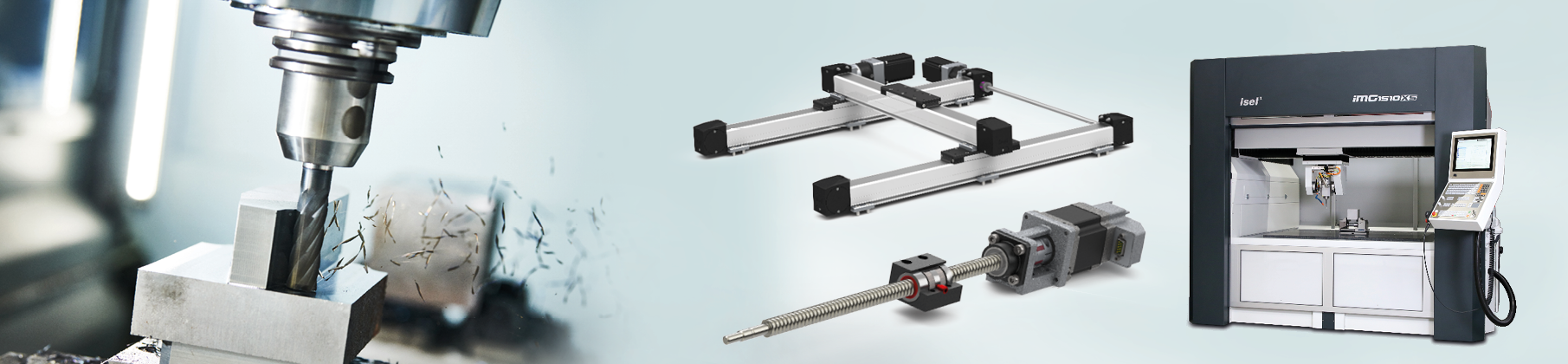

Product group Portal milling machines

Product NameCNC Milling Machine FlatCom® Series L

Technical Info

Travel ranges X/Y (L 150 | L 250) mm

Z-Hub mm

Z Diffuser* mm

Table clamping surface WxD (L 150 | L 250) mm

Product images

Description

Large machining areas up to 1700 x 2500 mm The FlatCom® L is a stable machine for cutting and non-cutting processing in the wood industry, advertising technology or also for various assembly work. With travels of 1700 x 2500 mm, it is the largest CNC machine in the extensive program of isel Germany AG. With extensions such as a vacuum table, speed-controlled spindle motors, tool changing stations in various designs or handling systems from our robotics division, you are equipped innovatively for the future. Options - Cooling spray device - coolmine - chip tray - Tool length probe - Spindle motors (can be used up to iSA2200) - Rotary changing systems SK 11 and SK 20 - Linear changing systems SK 11 and SK 20 - 4th axis with tailstock unit or e.g. assembly of the RDH series - 4th + 5th axis as rotary swivel axis - Engine room lighting LED - RAL special colour according to customer requirements - Pneumatic sliding door - Machine handwheel - safety light curtain - Size adjustment - Breakthroughs in the machine table - further doors laser safety glass Hood attachment closed CAD/CAM software Workpiece clamping systems (hand levers, vacuum plates, etc.) extraction systems rotating units Cutter breakage control Customer-specific adaptations Extension of valve terminals I/O distributor I/O Coding Mechanical height sensor Sealing air kit for milling motors Various postprocessors CAD/CAM Interface adaptations for laser devices PC control panel with free PCI slots (for use with external PCI hardware) stainless steel keyboard Milling and engraving spindles vacuum clamping tables suction device Closed or light-proof hood for laser applications Maximum 6 interpolated axes + 6 handling axes Portal passage according to customer requirements Best suited - multi-shift operation Processing of - Aluminium / light metals - milled plastics - Non-ferrous metals (brass, bronze, etc.) - ceramics - synthetic materials - wood Advantages - 5-axis machining - Large machining areas up to 1700 x 2500 mm - Gantry drive - movable portal, fixed table - Removable hood Translated with DeepL

{{ this.trans('product.manufacturer') }} {{ $parent.product.manufacturer }}

{{ this.trans('product.product_group') }} {{ $parent.product.producttype }} | {{ $parent.product.category.title }} {{ $parent.product.category.title }}

{{ this.trans('product.itemnumber') }} {{ $parent.product.itemnumber }}

{{ this.trans('product.techdata') }}

{{ key }}

{{ key }} {{ value }}

{{ this.trans('product.techinfo') }}

{{ key }} {{ value }}

Description

Product images