engineering to the point.

261

FollowersManufacturerisel Germany GmbH

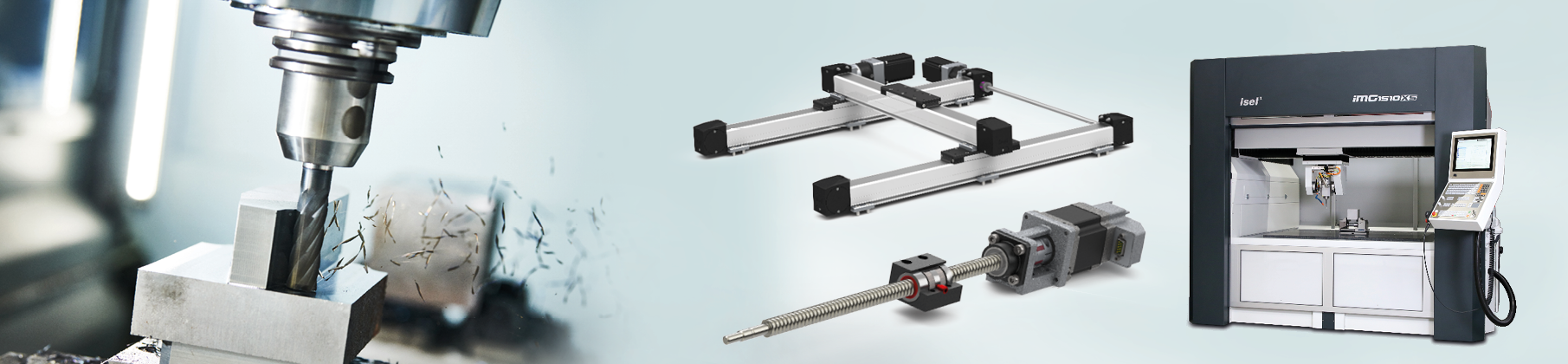

Product group Portal milling machines

Product NameCNC Milling Machine FlatCom - Series XL

Technical Info

Travel X1020 / 1420 mm

Travel Y720 / 1120 / 1620 / 2520 mm

Z-axis210 (optional 410, in each case without processing unit) mm

Z passage230 (optional 450, in each case without processing unit) mm

Product images

Description

FlatCom® Series XL (GFV/GFY) - with servo motor drive Robust CNC machine for 2.5 D/3D machining with a frame made from special aluminium profiles, a maintenance-free EC-drive and modern control software installed on the control panel.This machine guarantees maximum flexibility and e?ciency for the respective application due to its wide range of possible applications and combinations. Options cooling spray device coolmin blade tray tool length sensor spindle motors (up to iSA2200 applicable) round changing systems SK 11 and SK 20 linear changing systems SK 11 and SK 20 4th axis with tailstock unit 4th + 5th axis as rotary tilting unit LED-lighting RAL special colour according to customer requirements pneumatic sliding door machine handwheel safety light curtain size adjustment openings in the machine table further doors laser safety glass closed hood attachment CAD/CAM-Software Workpiece clamping systems (hand levers, vacuum plates, etc.) extraction systems rotating units cutter breakage control customer-specific adaptations extension of valve terminals I/O distributor I/O Coding mechanical height sensor sealing air kit for milling motors various postprocessors CAD/CAM interface adaptations for laser devices PC control console with free PCI plug-ins (for use by external PCI hardware) stainless steel keyboard milling and engraving spindles vacuum clamping tables suction device closed or light-proof hood for laser applications maximum 6 interpolated axes + 6 handling axes portal passage 435mm Ideally suited for multi-shift operation Machining of light metals, non frrous metals (brass, bronze etc.) CFRP Ceramic plastics wood Benefits 5-axis machining Windows-based software Gantry drive Mobile portal, fixed table Set up Portal: fixed, bench: moveable

{{ this.trans('product.manufacturer') }} {{ $parent.product.manufacturer }}

{{ this.trans('product.product_group') }} {{ $parent.product.producttype }} | {{ $parent.product.category.title }} {{ $parent.product.category.title }}

{{ this.trans('product.itemnumber') }} {{ $parent.product.itemnumber }}

{{ this.trans('product.techdata') }}

{{ key }}

{{ key }} {{ value }}

{{ this.trans('product.techinfo') }}

{{ key }} {{ value }}

Description

Product images