engineering to the point.

259

FollowersManufacturerisel Germany GmbH

Product group Robots for other applications

Product NameLINEAR TRACK - Series ILD with Linearmotors

Technical Info

Repeatability±0.01 mm

MotorDirect drive

Maximum Speed4.5 m/s

Maximum Length48 m

Maximum Acceleration10 m/s²

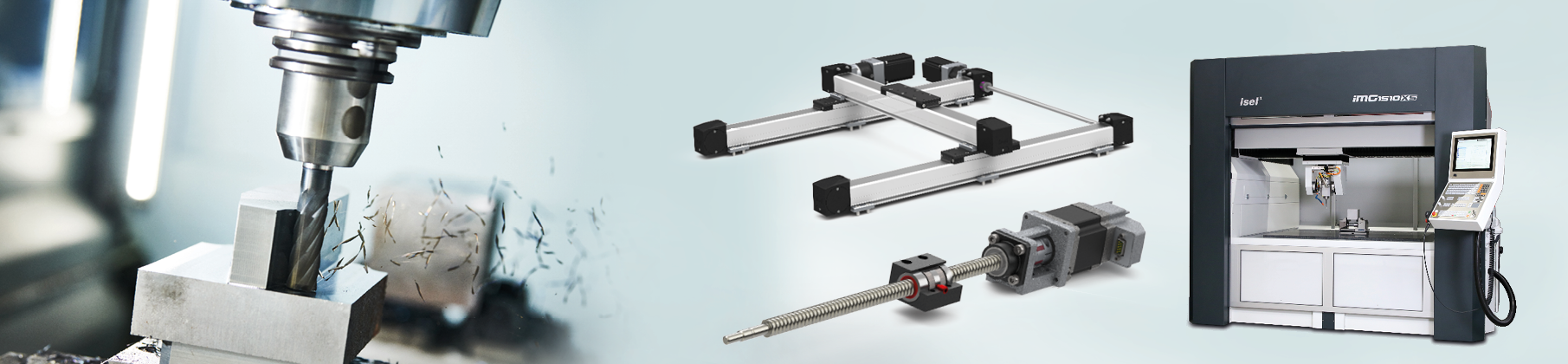

Product images

Description

Linear Track - ILD Series

Thank you for your interest in iselRobotik. Please submit the Addmit to Quote button above, enter your comments and we will contact you shortly.

The iLD linear track series can be integrated seamlessly into your system's handling area owing to its flexibility. Tracks are controlled in conjunction with our IWH series robots. This combination of linear tracks with isel robots makes for a very effective system and thus provides high throughputs. Depending on the application, installation can be below or to the side of the robot. The use of brushless servo motors makes linear tracks very responsive dynamically, low maintenance and quiet in operation.

Characteristics

- Maximum speed up to 4.5 m/s

- Maximum accekeration up to 10 m/s ²

- Overall lengths up to 15m

- Configurable lateral or bottom mounting

- Excellent structural rigidity

- Robust-industry-proven reliability and precision

- Simple to cennection to the robot controller

- Driven by Linear motor

- Free from wear

- Multiple motor operation

- Low-maintenance

- Made in Germany

{{ this.trans('product.manufacturer') }} {{ $parent.product.manufacturer }}

{{ this.trans('product.product_group') }} {{ $parent.product.producttype }} | {{ $parent.product.category.title }} {{ $parent.product.category.title }}

{{ this.trans('product.itemnumber') }} {{ $parent.product.itemnumber }}

{{ this.trans('product.techdata') }}

{{ key }}

{{ key }} {{ value }}

{{ this.trans('product.techinfo') }}

{{ key }} {{ value }}

Description

Product images