I will try and do a predrill hole. But everything looks correct...

Sent from my XT1635-01 using Tapatalk

Mastercam

Forum

Shaping the future of manufacturing

-

06-22-2019, 07:24 PMtruckeicRe: Fusion 360 Cam seems to make me use smaller bits then I would think

-

06-22-2019, 07:27 PMprecisionmetalRe: Fusion 360 Cam seems to make me use smaller bits then I would think

If you're so inclined, send me your f3d model via PM and I'll take a look at it.

-

06-22-2019, 07:37 PMtruckeicRe: Fusion 360 Cam seems to make me use smaller bits then I would think

-

06-22-2019, 08:08 PMprecisionmetalRe: Fusion 360 Cam seems to make me use smaller bits then I would think

sent you private msg

-

06-22-2019, 08:37 PMtruckeicRe: Fusion 360 Cam seems to make me use smaller bits then I would think

-

06-22-2019, 09:30 PMtruckeicRe: Fusion 360 Cam seems to make me use smaller bits then I would think

-

06-22-2019, 10:11 PMprecisionmetalRe: Fusion 360 Cam seems to make me use smaller bits then I would think

On the 2nd tab for your adaptive tool path, reduce minimum cutting radius from .0375" to .010" and you should be good to go.

-

06-22-2019, 10:13 PMtruckeicRe: Fusion 360 Cam seems to make me use smaller bits then I would think

-

06-22-2019, 10:20 PMprecisionmetalRe: Fusion 360 Cam seems to make me use smaller bits then I would think

The dimension between the inside walls you are machining is .438".

You're using a .375" end mill. Minimum radius was set at .0375", so double that is .075".

Add .075" to .375" and you have .450", which can't "fit" between the walls that are .438" apart.

Don't be tempted to just set this to zero or a very small number.... a machine needs to "move" when it's cutting an inside radius, and keeping this value at a realistic number is a good idea. As you can probably see, if you were "leaving stock" for a final/profile cleanup pass, it would be difficult to do this roughing with a 3/8" end mill. Might need to go to something just a bit smaller in that hypothetical scenario.

PM -

06-22-2019, 10:46 PMtruckeicRe: Fusion 360 Cam seems to make me use smaller bits then I would think

Ok so I just tried it and it worked.. so min radius from the help menu in Fusion says that it will leave sharp edges.

So is that how to figure it.. if it was set to .0375 you double that number and add to the cutter?

Did you run my CAM?

Maybe it is not really doing this, but the backend of that pocket (where the cutter was not going before we changed that min radius) looks like there is a small area it's not cutting..

Am I just seeing things?

Thanks for the help!

Sent from my XT1635-01 using Tapatalk -

06-22-2019, 11:27 PMprecisionmetalRe: Fusion 360 Cam seems to make me use smaller bits then I would think

It looks OK on my computer, though if it was me, I'd probably put a piece of machinable wax in the machine and run your tool paths on an expendable piece of material before going after the real part.

Personally I'd approach this a bit differently: drill a series of holes down the center to get the majority of the material out, then remove the balance of the material fairly aggressively but leave maybe .010" stock on the walls, then finish up with a profile pass.

Is your blank 6061 or 7075? All those little step-downs will be hard on the corners of that 3/8" end mill. I rarely do any roughing with an end mill that doesn't have a corner radius, then if necessary, I'll make a final pass on the floor with a square-corner end mill. -

06-23-2019, 01:33 AMtruckeicRe: Fusion 360 Cam seems to make me use smaller bits then I would think

-

06-23-2019, 02:09 AMprecisionmetalRe: Fusion 360 Cam seems to make me use smaller bits then I would think

No no... not a ball end mill, just one with a bit of a corner radius. Typically called a "bull nose", but actually all that's required is a .005" or .010" corner radius and they hold up WAY better. :-)

-

06-23-2019, 02:23 AMtruckeicRe: Fusion 360 Cam seems to make me use smaller bits then I would think

-

06-23-2019, 03:20 AMprecisionmetalRe: Fusion 360 Cam seems to make me use smaller bits then I would think

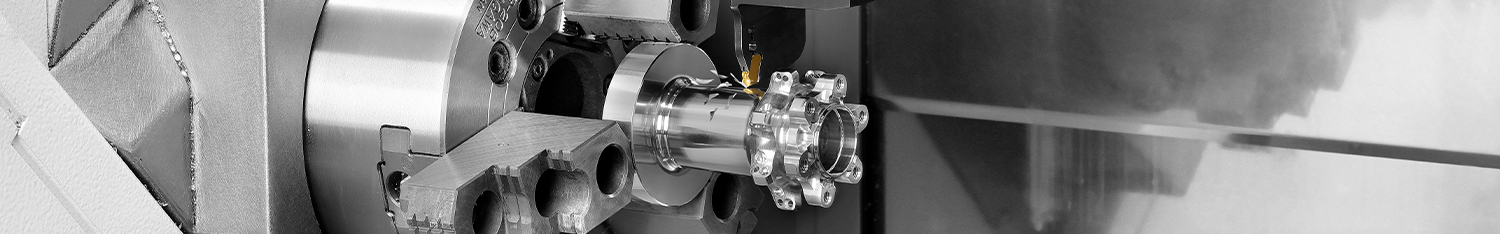

Corner radius:

Attachment 422768 -

06-25-2019, 02:11 PMtruckeicRe: Fusion 360 Cam seems to make me use smaller bits then I would think

Thanks for everyone that posted and helped I truly appreciate it!