Compact, safe, automated - even in a limited space

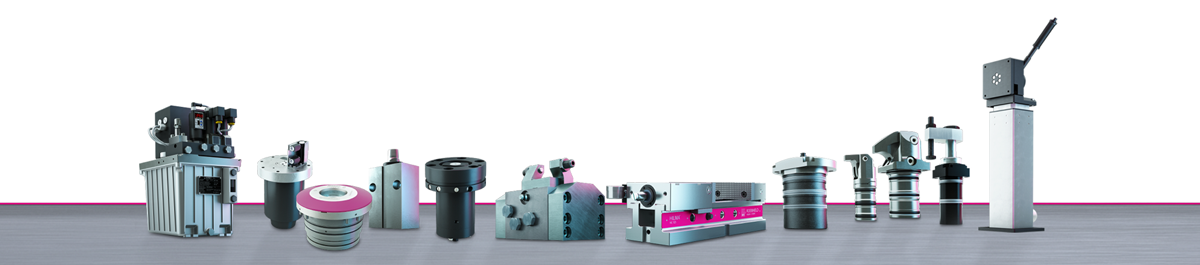

Laubach, in August 2013. With numerous innovations in power workholding ROEMHELD present themselves from September 16 to 21, 2013 at the EMO.

Included in particular are compact elements, components for increased safety, automation solutions for purely mechanical clamping systems and zero-point mounting systems for piece production. Furthermore, ROEMHELD shows the new cost-effective hinge clamp for simple clamping tasks and demonstrates the application possibilities for electrical clamping technology. At the EMO you will find ROEMHELD in Hall 4 at Stand E42.

Clamping in a very limited space

For safe and reliable use of hydraulic clamping fixtures in a very limited space, the company is presenting two new products: A compact intensifier with integrated check valve and a standardised valve module combination. The intensifier transforms a low input pressure into a higher output pressure so that more compact clamping elements can be used, the check valve shuts off the high pressure. With the valve module combination complex hydraulic fixtures can be controlled in limited space. Since all control and pressure valves are firmly installed, the cost for piping will be minimized and the space required will be saved.

Protection against machine damage

Also wireless pressure monitoring serves for safety, since pressure drops on hydraulic clamping fixtures can be recognized early and thus machine damages can be avoided. The component, that has already been presented at the Euromold 2012, has been installed successfully at several customers and is now included in the ROEMHELD catalogue. By means of an electronic sensor, fixture pressures up to 500 bar can be monitored via radio on machines at a maximum distance of 300 m.

A pressure drop will be displayed immediately; optionally the values can be shown at an RS485 interface as an analogue or digital signal. The receiver and the battery-powered transmitter, protected against coolant and swarf, can be easily adjusted, with one receiving unit 16 transmitters can be controlled.

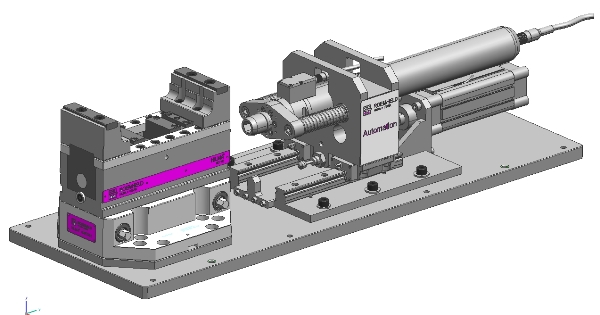

Automation from batch of 1: Now also purely mechanically

Around the topic of automation ROEMHELD offers a new compact clamp giving a signal as soon as the unclamping position is reached and an extension of the already presented, modular automation solution for workpiece machining from batch of 1. New is the fact that in addition to the previously available hydraulic components with stroke measurement now also mechanical clamping systems are offered. The automated solution - optionally mountable in horizontal or vertical position - can be used as comprehensive, flexible and diverse alternative to conventional pallet systems. Without its own power supply on the pallet or in the machinery space it can easily be retrofitted to existing mechanical clamping systems.

All the components used are standard products that are quickly available and can be combined without any problems and are easily expandable for changed tasks.

The automation module consists of a control and a screw system. Different workpiece dimensions can be set automatically at the clamping system. Various control functions ensure a high level of process safety: On the screw module also the clamping force and – via the swing angle – the position of the clamping jaws are controlled and monitored.

The modular automation solution for workpiece machining from batch of 1

is now also available for purely mechanical clamping systems

New zero-point mounting system especially for single clamping

Both fully automated and manually-loadable, the new zero-point mounting system "Speedy classic 2 Twister NG" is especially indicated for single clamping.

It is characterized by high precision with µ-exact positioning, a very high force absorption and a backlash-free form fit and thus an extremely high rigidity. Thanks to its high positioning accuracy and easy handling it is also particularly indicated for manual loading and can also be used as zero-point mounting system in automatic production.

The appropriate pallets can easily be manufactured by the customer himself according to the specifications to save time and money. The zero-point mounting system is available as hydraulic and pneumatic variant and can be combined with other components as "Speedy classic 2 Twister".

Both fully automated and manually-loadable the new zero-point mounting system

"Speedy classic 2 Twister NG", is especially indicated for single clamping

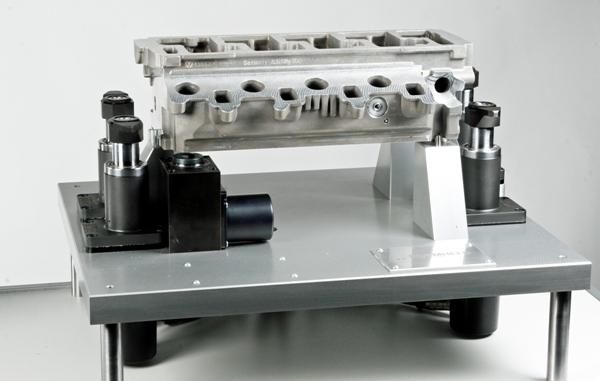

Electro-mechanical clamping technology in use

As an application example for electro-mechanical clamping elements of the series E-TEC ROEMHELD shows at the stand a cylinder head fixture with hydraulic-free components. The clamping systems shown at the last EMO are well received in the market, the frequent use on test benches for motors and gearboxes demonstrates

their precision and reliability.

As an application example for electro-mechanical clamping elements of the series

E-TEC ROEMHELD shows at the stand a cylinder head fixture with hydraulic-free components

Pictures: ROEMHELD

Editorial responsibility is held by: Römheld GmbH

Germany

Germany