Especially for contract manufacturers and companies who want to automate their production processes, ROEMHELD presents at the Metav a wide range of flexible workholding elements and systems. The elements can be quickly adapted to changing manufacturing conditions and are suitable for the use in pallet stations, for example. ROEMHELD exhibits in Hall 14, stand C92.

The Vario Line machine vice from HILMA with quickly exchangeable jaws ensures short set-up times and the tower workholding system TS allows simultaneous clamping of up to 16 workpieces.

If components have to be manufactured on several machines, the zero point clamping systems from STARK enable comfortable and precise handling. At the Metav, systems for beginners as well as completely automatable elements such as the double-acting “System 3000” are presented.

The stand presentation is completed by slim work supports that can hold workpieces even in recesses and cavities which are difficult to access, very flat hinge clamps, eccentric bore clamps for 5-sided machining and a wireless pneumatic pressure monitoring for clamping elements.

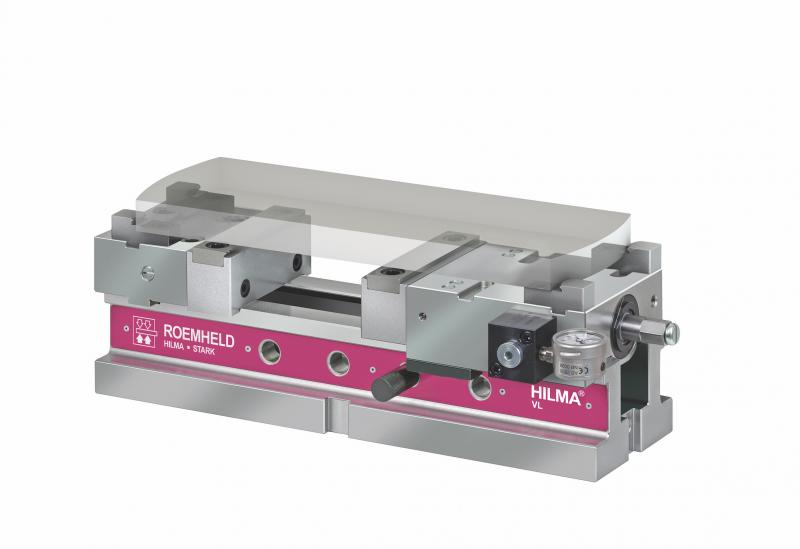

HILMA Vario Line: a clamping system for many applications

For quickly changing manufacturing tasks and workpiece sizes, machine vices of the series HILMA Vario Line are recommended. They can be quickly adapted to the specific requirements by numerous parameters and can be used both in vertical and horizontal applications. The quick- change jaws can be changed with one touch within seconds. As an option, a clamping force display for continuous and exact clamping force application and control is available.

The all-rounder HILMA MC-P

Three different clamping types are possible with the series MC-P. Concentric clamping, clamping against fixed jaw and floating clamping. For clamping without deformation of complex or delicate components such as bars, rails, profiles or housings, the workholding system MC-P balance was designed. The MC-P workholding systems are mainly used in 5-axis machining. The patented segment design ensures a high degree of stability and precision. Thus, raw and finished parts can be machined without retrofitting in one system. The sturdy design with integrated swarf protection facilitates the use in pallet stations.

First choice in horizontal machining: Tower workholding systems TS

ROEMHELD offers with the series TS a suitable tower workholding system for horizontal machining task with manual, semi-automatic or fully automatic manufacturing. 4, 8 or 16 workpieces can be clamped at the same time. The patented guide and sealing system ensure a high degree of stability, precision and swarf protection.

Besides the proven system with third-hand function, the new series TS Vector for the manufacturing of heavy workpieces is exhibited. Also, there is the hydraulic type TS H which has been developed for automated processes.

External preparation with machine vice and zero point clamping system

For small batch sizes or large batch sizes, in fully automated systems or for manufacturing with short cycle times – the flexible and low-cost zero point clamping systems of the series SPEEDY basic are very versatile. The clamping elements reduced to the essential are available with five different diameters between 26 and 148 mm. They can be used both individually and in combination on a quick-locking plate. Thanks to their low installation depth and simple built-in contour, they can be easily retrofitted.

You can find a SPEEDY basic clamping element, for example, in combination with a HILMA machine vice MC for 5-axis machining. Together, they allow external preparation as well as quick and zero-point accurate change of workpieces and fixtures.

Easy and safe coupling with easy click

Also compact is the zero point clamping systems SPEEEDY easy click. The elements, which are used as modules in plates or directly in the machine table, have a diameter of 85 mm and a height of 19 mm. A short click is sufficient to generate a retention force of up to 10 kN. On the fair you can see the element as part of the STARK multi-media coupling that considerably facilitates the coupling processes with several lines.

The coupling equipped with easy click cannot only be quickly fixed but also secured by the machine control or the used power unit. Only after release, it can be removed from the parking station and clicked in the desired place.

Germany

Germany