At this year's Automatica, ROEMHELD presented components and systems for an efficient, partly automated and Industry 4.0 capable hand assembly.

The group of companies showed, among other things, two workplace solutions for the assembly of differential gears and brake cylinders. For the first time, ROEMHELD was at the trade fair in Munich.

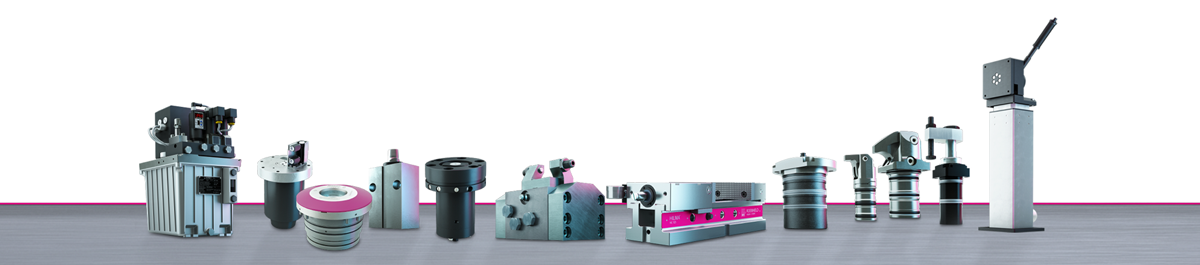

The ROEMHELD stand offered the trade fair visitors also a wide selection of clamping technology products on the topic of Industry 4.0, including the electrically operated clamping elements of the E-TEC series, components for automated workpiece clamping and modules for wireless remote monitoring of fixture pressures. Also, press-in devices from the modular range of assembly and handling technology were presented.

Access to production data from any browser-compatible mobile device is possible

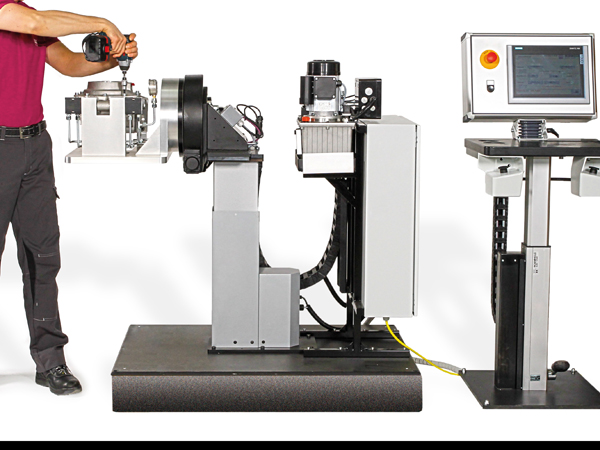

One of the fair premieres was the command module equipped with new functions of the modulog handling system for partly automated hand assembly. With the command module, it is now possible to get mobile access to production data in real time from any browser-compatible terminal so that a location-independent production monitoring is possible. A new feature is a time recording function for the assembly fitter. The command unit can also show the progress of production and the assembled piece numbers. With personalised Euchner Keys, the unit recognises the employee and ergonomically optimises the working place according to its size.

Quick, safe and flexible assembly thanks to partial automation

The use of components from the modulog range increases the efficiency in the last production step, the assembly, and makes manual work more productive and more flexible. Particularly with a high number of component variants, partly automated work processes contribute to optimised set-up times, stable processes as well as safe and ergonomically optimised processes. How such a hand assembly can look like, shows ROEMHELD at the fair based on workplace solutions with coordinated lifting, rotating and tilting modules as well as quick clamping systems.After logging on to the command module, the respective personal information for the operator is automatically retrieved and the time recording is started. Then the operator transports the workpiece mounted with a quick clamping system on a fixture with a picking cart to the assembly working place. Using a RFID chip, the workpiece is detected and automatically clamped with the correct force on the rotating module; clamping errors are thus excluded. The component is now continuously movable in both directions, the indexing angle can be freely selected. An additional tilting module enables the swivelling of the workpiece to axis values between 0° and 90° and thus increases the accessibility for the fitter.

Time savings by automated clamping

If besides the fixtures and components of the assembly working places, also the used machines are equipped with uniform quick clamping systems, the workpieces can be quickly, precisely and easily clamped in the entire production. Especially in the case of working places with frequent workpiece change and for components that are routed via several stations, the achieved time savings are often significant.

Better accessibility of the workpiece for the fitter

By the combination of the individual modules for rotating, swivelling and lifting, a variety of workpiece positions can be obtained without repositioning; assembly in different places is significantly easier and safer. Since the interface of the rotating module is equipped with flow power for air, oil and electrical signals, an annoying and time-consuming external piping or wiring is not required. All modulog components can be controlled both directly by hand panel or foot pedal as well as on the 12-inch touch panel of the command module. On the touch panel, the operator can access a wide range of preset work sequences or even program new processes.

Germany

Germany