SCHUNK - Gripping and Clamping

Products

Clamping devices

Lathe chucks, hand operated

ROTA-S flex

|

Lathe Chucks

SCHUNK SE & Co. KG

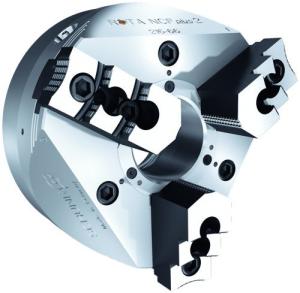

Lathe chucks, hand operated

Description

Weight-reduced 3-jaw manual chuck with quick jaw adjustment and an extremely wide clamping range

Field of application

on mill/turn machines

Advantages – Your benefits

- Convenient jaw quick-change system. Minimizing set-up times and costs.

- High efficiency of the wedge bar system. Process-reliable clamping due to high clamping forces.

- High jaw quick-change repeatability. No reboring of already machined jaws necessary.

- Low chuck weight. Higher workpiece payload possible.

- Specially sealed for vertical designs. Optimum protection against coolant and chips.

- Maximum flexibility due to extended guideways. For an extremely wide clamping range.

- Visual safety devices. Maximum operating safety.

- Optimized lubrication system. For consistently high clamping forces.

- Angled serrated base jaws SFG. Interchangeable with ROTA-S plus and with system “F“ (Forkardt).

- All functional parts are ground and hardened. High run-out and jaw change repeat accuracy.

ROTA-S plus 2.0

|

Lathe Chucks

SCHUNK SE & Co. KG

Lathe chucks, hand operated

Description

Universal 3-jaw manual chuck with jaw quick-change system for maximum operating safety

Field of application

- on conventional lathes

- on cycle-controlled lathes

- on mill/turn machines

- on drill / boring machines

- on welding systems

- on special machines

Advantages – Your benefits

- Convenient jaw quick-change system. Minimizing set-up times and costs.

- Large through-hole. Machining of all standard pipe diameters.

- High efficiency of the wedge bar system. Process-reliable clamping due to high clamping forces.

- High jaw quick-change repeatability. No reboring of already machined jaws necessary.

- Visual safety devices. Maximum operating safety.

- Optimized lubrication system. Consistently high clamping forces are ensured.

- Modular center sleeve system. Optimum adjustment to new clamping tasks due to exchangeable center sleeves.

- Excellent clamping force/torque ratio. Perfect use of the machine performance.

- Angled serrated base jaws SFG. Interchangeable with ROTA-S plus and with system “F“ (Forkardt).

- Ergonomic, light safety spanner wrench. Ensures easy operation.

- All functional parts are ground and hardened. High run-out and jaw change repeat accuracy.

Lathe chucks, hydraulically operated

ROTA 2B

|

Lathe chuck, hydraulically operated

SCHUNK SE & Co. KG

Lathe chucks, hydraulically operated

Description

Lightweight 2-jaw power lathe chuck with long jaw stroke, and at the same time high clamping force and pre-installed media feed-through. Particularly suitable for clamping fittings.

Field of application

on universal CNC lathes

on turn/mioll centers

on vertical lathes

Advantages – Your benefits

Precision wedge hook power chuck for highest quality requirements

Allows excellent machining processes

High efficiency of the wedge hook system

Process-reliable clamping due to high clamping forces

Optimum jaw support for O.D. and I.D. clamping due to a very long base jaw guidance

Allows high clamping forces at a long service life

Optimized lubrication system

Consistently high clamping forces are ensured

Largest jaw stroke at high jaw clamping force

Safe and variable clamping of workpieces over interfering contours

Media feed-through (coolant or air) as option integrated in the chuck body

Flexibility depending on the application

Low height

Maximum use of the machine room and maximum rigidity of the system

Base jaws with fine serration or tongue and groove as standard

High flexibility in the range of top jaws

Low chuck weight

Fast acceleration and deceleration operations shorten the cycle times

Also applicable as stationary clamping device with base frame cylinder

Perfectly suitable for machining centers

All functional parts are ground and hardened

Ensures a long service life

Options and special information

Extremely long jaw strokes and high clamping forces are what make the ROTA 2B 2-jaw power chuck from SCHUNK stand out from the crowd. Especially recommended for clamping fittings.

Standard mounting threads allow many ways of mounting workpiece stops or consoles. Adjustable brass wipers seal the base jaws and offer an excellent protection against water and dirt. The therefrom resulting low wear ensures a long lifetime of the chuck.

ROTA NC plus 2

|

Lathe chuck

SCHUNK SE & Co. KG

Lathe chucks, hydraulically operated

Description

Weight-reduced 3-jaw precision power chuck in an extremely stable design.

Field of application

on universal CNC lathes

on turn/mioll centers

on vertical pick-up lathes

Advantages – Your benefits

Precision wedge hook power chuck for highest quality requirements

Allows excellent machining processes

Large through-hole

Machining of all standard pipe diameters

High efficiency of the wedge hook system

Process-reliable clamping due to high clamping forces

Optimized lubrication system

Consistently high clamping forces are ensured

Modular center sleeve system

Optimum adjustment to new clamping tasks due to exchangeable center sleeves

Double-guided chuck piston

For highest run-out and repeat accuracy

Low chuck weight

Fast acceleration and deceleration operations shorten the cycle times

All functional parts are ground and hardened

Ensures a long service life

Options and special information

The power chuck was developed to meet the highest demands on modern lathes. Very robust, hardened and ground flat guidances ensure process-stable functioning even at maximum load. The modular sealed center sleeve system increases flexibility for the most various applications in everyday life.

Due to the newly developed lubrication system, the service intervals of the lathe chuck are extended. Repeatability and clamping force are also improved in the long term.

ROTA NCD

|

ROTA NCD

SCHUNK SE & Co. KG

Lathe chucks, hydraulically operated

Description

Universal, wedge-bar-based, 3-jaw power chuck with continuous T-slot in the base jaws for maximum jaw adjustment range. Available as 2-jaw chuck on request.

Field of application

on universal CNC lathes

on turn/mioll centers

on vertical pick-up lathes

Advantages – Your benefits

Large through-hole

Machining of all standard pipe diameters

High efficiency of the wedge bar system

Process-reliable clamping due to high clamping forces

Optimum jaw support for O.D. and I.D. clamping due to a very long base jaw guidance

Allows high clamping forces at a long service life

Extremely rigid clamping

High precision on the workpiece

Clamping of smallest diameters possible

Flexibility for various clamping tasks

Base jaws with fine serration 1.5 mm x 60° and 1/16" x 90° as standard

High flexibility in the range of top jaws

Two mounting bolt circles

For fast and direct attachment to all commercially available spindle heads

All functional parts are ground and hardened

Ensures a long service life

Options and special information

The design of the SCHUNK wedge bar power chuck ROTA NCD is based on the patented idea of high-precision clamping of the smallest workpiece diameters with SCHUNK collet jaws. At the same time it is possible to clamp large workpieces with all conventional top jaws. The continuous T-slot in the base jaws allows for the highest flexibility in positioning the top jaws.

ROTA NCE

|

Lathe chuck, hydraulically operated

SCHUNK SE & Co. KG

Lathe chucks, hydraulically operated

Description

Extremely lightweight 3-jaw power chucks with innovative design for large savings potential with dynamic processes. The chuck is ideal for use on machines with short-stroke cylinders.

Field of application

on universal CNC lathes

on turn/mioll centers

on vertical pick-up lathes

Advantages – Your benefits

Energy efficient thanks to extremely low moment of inertia

Shorter cycle times and reduced energy costs

Connection dimensions 100% compatible with power lathe chucks of the Kitagawa BB200 series (up to size 260)

Exchange of the existing Kitagawa chucks can be done within short time

Precision wedge hook power chuck for highest quality requirements

Allows excellent machining processes

High efficiency of the wedge hook system

Process-reliable clamping due to high clamping forces

Optimized lubrication system

Consistently high clamping forces are ensured

Modular center sleeve system

Optimum adjustment to new clamping tasks due to exchangeable center sleeves

Base jaws with tongue and groove or fine serration as standard

High flexibility in the range of top jaws

Blank draw nut which can be disassembled and removed is integrated in the chuck

Boring out draw bar thread or for exchanging with the already bored-out draw nut of a Kitagawa BB200 chuck of the same size can be carried out by the customer himself

All functional parts are ground and hardened

Ensures a long service life

Options and special information

The SCHUNK ROTA NCE unifies lightweight construction, maximum bearing load capacity and an extraordinary formal language all in one. The geometry of the lathe chuck was adapted to the power flow so that despite the lightweight geometry, a maximum rigidity is ensured.Compared to conventional lathe chucks, the inertia was reduced by up to 40% depending on the model size.

In doing so, the SCHUNK ROTA NCE provides the ideal requirements for a high process dynamics and productivity with minimum energy consumption. Particularly in line production, the energy and cycle time-efficient lathe chuck promises significant savings and is also ideally suitable for the energy management certification DIN EN ISO 50001.

ROTA NCF plus 2

|

Lathe Chucks

SCHUNK SE & Co. KG

Lathe chucks, hydraulically operated

Description

Weight-reduced 3-jaw precision power chuck with centrifugal force compensation in an extremely stable design.

Field of application

- on universal CNC lathes

- on turn/mioll centers

- on vertical pick-up lathes

Advantages – Your benefits

- Precision wedge hook power chuck for highest quality requirements. Allows excellent machining processes.

- Very high RPM without essential clamping force reduction. Optimum utilization of the lathe chuck performance due to high economic efficiency.

- With integrated centrifugal force compensation. Thereby high machining speeds are possible.

- Large through-hole. Machining of all standard pipe diameters.

- High efficiency of the wedge hook system. Process-reliable clamping due to high clamping forces.

- Optimized lubrication system. Consistently high clamping forces are ensured.

- Modular center sleeve system. Optimum adjustment to new clamping tasks due to exchangeable center sleeves.

- Double-guided chuck piston. For highest run-out and repeat accuracy.

- Low chuck weight. Fast acceleration and deceleration operations shorten the cycle times.

- All functional parts are ground and hardened. Ensures a long service life.

ROTA NCK plus

|

Lathe chuck

SCHUNK SE & Co. KG

Lathe chucks, hydraulically operated

Description

Universal 3-jaw power chuck with exceptional price-performance ratio. 100% compatible with the Kitagawa B200 series.

Field of application

on universal CNC lathes

on turn/mioll centers

on vertical pick-up lathes

Advantages – Your benefits

Interface 100% compatible with power chucks of the Kitagawa B200 series

Exchange of the existing Kitagawa chucks can be done within short time

Precision wedge hook power chuck for highest quality requirements

Allows excellent machining processes

High efficiency of the wedge hook system

Process-reliable clamping due to high clamping forces

Optimized lubrication system

Consistently high clamping forces are ensured

Base jaws with fine serration 1.5 mm x 60° and 1/16" x 90° as standard

High flexibility in the range of top jaws

Blank draw nut which can be disassembled and removed is integrated in the chuck

Turning for draw tube threads or replacement of the already turned center sleeve

Modular center sleeve system

Optimum adjustment to new clamping tasks due to exchangeable center sleeves

All functional parts are ground and hardened

Ensures a long service life

Options and special information

With the design of the wedge hook power chuck ROTA NCK plus, SCHUNK offers a chuck for everyday applications on CNC-lathes at a reasonable price. The chuck distinguishes by high clamping forces and highest precision during endurance applications.

The ROTA NCK plus is compatible with the Kitagawa B200 series. This allows the exchange of an already existing lathe chuck in a minimum of time.

ROTA NCK-S plus

|

Lathe chuck

SCHUNK SE & Co. KG

Lathe chucks, hydraulically operated

Description

Hydraulically actuated 3-jaw power chuck in compact design with a high clamping force

Field of application

3-axis standard machining center

4-axis vertical machining center

4-axis horizontal machining center

5-axis machining center

5-axis machining center with turning option

Advantages – Your benefits

Precision wedge hook power chuck for highest quality requirements

Allows excellent machining processes

Excellent cost-performance ratio

Optimum use of the lathe chuck

High efficiency of the wedge hook system

Process-reliable clamping due to high clamping forces

Optimized lubrication system

Consistently high clamping forces are ensured

Integrated hydraulic cylinders

Delicate clamping due to large control range

Base jaws with fine serration 1.5 mm x 60° and 1/16" x 90° as standard

High flexibility in the range of top jaws

Low height

Maximum use of the machine room and maximum rigidity of the system

All functional parts are ground and hardened

Ensures a long service life

Options and special information

Hydraulic power chucks for stationary use

The extremely flat, precision wedge hook power chuck ROTA NCK-S plus with integrated hydraulic cylinder is a price-attractive clamping solution for stationary use. High clamping forces and accuracy make the chuck the ideal clamping device for daily use.

The ROTA NCK-S plus has an one-piece, hardened chuck body, long jaw guidances as well as a long and precise piston guidance. Due to the integrated lubrication of the wedge hook and wear-resistant parts, the sturdy and versatile chuck can also be easily maintained.

ROTA NCO

|

Lathe chuck

SCHUNK SE & Co. KG

Lathe chucks, hydraulically operated

Description

Universal, 3-jaw power chuck with outstanding sealing, long jaw stroke and integrated media feed-through.

Field of application

on universal CNC lathes

on vertical turret lathes

on mill/ turn machines

on vertical pitch-up lathes

Advantages – Your benefits

Precision wedge hook power chuck for highest quality requirements

Allows excellent machining processes

High efficiency of the wedge hook system

Process-reliable clamping due to high clamping forces

Optimum jaw support for O.D. and I.D. clamping due to a very long base jaw guidance

Allows high clamping forces at a long service life

Optimized lubrication system

Consistently high clamping forces are ensured

Largest jaw stroke at high jaw clamping force

Safe and variable clamping of workpieces over interfering contours

Sealed against cooling lubricant and chips as standard via wiper strips, seals and sealed toolholder through bore

Excellently suitable for the use on vertical lathes

Media feed-through (coolant or air) as standard option integrated in the chuck body

Flexibility depending on the application

Low height

Maximum use of the machine room and maximum rigidity of the system

Base jaws with fine serration 1.5 mm x 60° and 1/16" x 90° as standard

High flexibility in the range of top jaws

All functional parts are ground and hardened

Ensures a long service life

Options and special information

The wedge hook power chuck is excellently protected against dirt and chips. The technology of the ROTA NCO ensures highest precision and life time for applications on horizontal as well as vertical lathes. The long jaw stroke allows for clamping around interfering contours.

Due to the media feed-through, the ROTA NCO chuck is a multi-purpose chuck. Central coolant supply, air feed-through or central lubrication are already standardized options and the chuck body is equipped for these modification possibilities.

ROTA NCR

|

Lathe chuck

SCHUNK SE & Co. KG

Lathe chucks, hydraulically operated

Description

6-jaw power chuck with oscillation mechanism for low-deformation clamping of thin-walled components. Also available with additional centrifugal force compensation system.

Field of application

on universal CNC lathes

on vertical turret lathes

on mill/turn machines

on vertical lathes

Advantages – Your benefits

Precision angle lever power chuck for top quality demands

Allows excellent machining processes

High efficiency of the angle lever system

Process-reliable clamping due to high clamping forces

Optimum jaw support for O.D. and I.D. clamping due to a very long base jaw guidance

Allows high clamping forces at a long service life

Optimized lubrication system

Consistently high clamping forces are ensured

Media feed-through (coolant or air) as standard option integrated in the chuck body

Flexibility depending on the application

Low height

Maximum use of the machine room and maximum rigidity of the system

On request also available with centrifugal force compensation

Less clamping force loss at high RPM

Deformation sensitive clamping of thin-walled workpieces

High degree of roundness of the workpieces

Very accurate clamping of non-circular components

Perfect for castings

Turning ring simplifies and optimizes top jaw boring/machining

Easy handling during boring/machining top jaws

All functional parts are ground and hardened

Ensures a long service life

Options and special information

The 6-jaw compensation chuck is based on the principle of chuck jaws that oscillate in pairs. Two base jaws are always connected with a pendulum body. This ensures workpiece centering between six contact points, which can be adjusted in pairs. Even raw parts can be centered without distortion of the workpiece.

For specific applications, the pendulum compensation can be blocked resulting in the centric clamping of the jaws.

ROTA NCS 3

|

Lathe chuck

SCHUNK SE & Co. KG

Lathe chucks, hydraulically operated

Description

Hermetically sealed, 3-jaw power chuck with active jaw pull-down function.

Field of application

on universal CNC lathes

on turn/mioll centers

on vertical lathes

Advantages – Your benefits

Precision lever power chuck for top quality demands

Allows excellent machining processes

High efficiency of the lever system

Process-reliable clamping due to high clamping forces

Hermetically sealed

Optimum protection against coolant and chips

Permanently filled with oil

Almost maintenance free with constant clamping force

Active jaw pull-down

No lifting of the workpiece from chuck face, highest requirements in face parallelism

Media feed-through (coolant or air) as standard option integrated in the chuck body

Flexibility depending on the application

With integrated centrifugal force compensation

Thereby high machining speeds are possible

Easy change of base jaws

Suitable for external and internal clamping

All functional parts are ground and hardened

Ensures a long service life

Options and special information

The ROTA NCS is a hermetically sealed power lathe chuck with active pull-down action of the jaws. The chuck is suitable for external and internal clamping applications, the chuck size has to be selected for the corresponding workpiece size. The ROTA NCS is centrically clamping.

The ROTA NCS is almost maintenance free, optimized for use in horizontal and vertical applications in high volume production.

ROTA NCS 6

|

Lathe chuck

SCHUNK SE & Co. KG

Lathe chucks, hydraulically operated

Description

Hermetically sealed, 6-jaw power chuck with active jaw pull-down function.

Field of application

on universal CNC lathes

on turn/mioll centers

on vertical lathes

Advantages – Your benefits

Precision lever power chuck for top quality demands

Allows excellent machining processes

High efficiency of the lever system

Process-reliable clamping due to high clamping forces

Hermetically sealed

Optimum protection against coolant and chips

Permanently filled with oil

Almost maintenance free with constant clamping force

Active jaw pull-down

No lifting of the workpiece from chuck face, highest requirements in face parallelism

Media feed-through (coolant or air) as standard option integrated in the chuck body

Flexibility depending on the application

With integrated centrifugal force compensation

Thereby high machining speeds are possible

Easy change of base jaws

Suitable for external and internal clamping

Deformation sensitive clamping of thin-walled workpieces

High degree of roundness of the workpieces

Very accurate clamping of non-circular components

Perfect for castings

All functional parts are ground and hardened

Ensures a long service life

Options and special information

The ROTA NCS is a hermetically sealed power lathe chuck with active pull-down action of the jaws. The chuck is suitable for external and internal clamping applications, the chuck size has to be selected for the corresponding workpiece size. The ROTA NCS is centrically clamping.

At the 6-jaw chuck the pendulum mechanism is integrated. This assures workpiece centering between six contact points, which can be adjusted in pairs. Even pre-machined parts can be centered without distortion of the workpiece.

The ROTA NCS is almost maintenance free, optimized for use in horizontal and vertical applications in high volume production.

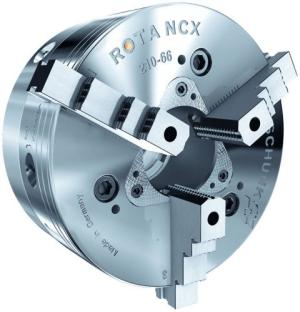

ROTA NCX

|

Lathe Chucks

SCHUNK SE & Co. KG

Lathe chucks, hydraulically operated

Description

3-jaw power lathe chuck with jaw quick-change system for small batch sizes and the easiest exchange of existing lathe chucks with fine serration. 100 % compatible with the power lathe chuck of the Kitagawa BB200 series.

Advantages – Your benefits

- Convenient jaw quick-change system. Minimizing set-up times and costs.

- Large through-hole. Machining of all standard pipe diameters.

- High efficiency of the wedge bar system. Process-reliable clamping due to high clamping forces.

- High jaw quick-change repeatability. No reboring of already machined jaws necessary.

- Optimized lubrication system. Consistently high clamping forces are ensured.

- Interface 100% compatible with power chucks of the Kitagawa BB200 series. Exchange of the existing Kitagawa chucks can be done within short time.

- Blank draw nut which can be disassembled and removed is integrated in the chuck. Turning for draw tube threads or replacement of the already turned center sleeve.

- All functional parts are ground and hardened. High run-out and jaw change repeat accuracy.

ROTA THW plus

|

Lathe Chucks

SCHUNK SE & Co. KG

Lathe chucks, hydraulically operated

Description

Universal 3-jaw power chuck with jaw quick-change system and maximum operating safety

Field of application

- on universal CNC lathes

- on turn/mioll centers

- on vertical pick-up lathes

Advantages – Your benefits

- Convenient jaw quick-change system. Minimizing set-up times and costs.

- Large through-hole. Machining of all standard pipe diameters.

- High efficiency of the wedge bar system. Process-reliable clamping due to high clamping forces.

- High jaw quick-change repeatability. No reboring of already machined jaws necessary.

- Optimized lubrication system. Consistently high clamping forces are ensured.

- Modular center sleeve system. Optimum adjustment to new clamping tasks due to exchangeable center sleeves.

- GBK straight-serrated base jaws. Compatible to ROTA-G and system “R“ (Reishauer).

- Two mounting bolt circles. For fast and direct attachment to all commercially available spindle heads.

- All functional parts are ground and hardened. Ensures a long service life.

ROTA-G

|

Lathe chuck

SCHUNK SE & Co. KG

Lathe chucks, hydraulically operated

Description

Universal 3-jaw manual chuck with jaw quick-change system for straight serrated jaws

Field of application

on conventional lathes

on cycle-controlled lathes

on mill/turn machines

on drill / boring machines

on welding systems

on special machines

Advantages – Your benefits

Convenient jaw quick-change system

Minimizing set-up times and costs

Hardened and extremely rigid base body

Therefore a longer life span at highest precision. Even with maximum clamping force

Large through-hole

Machining of all standard pipe diameters

High efficiency of the wedge bar system

Process-reliable clamping due to high clamping forces

High jaw quick-change repeatability

No reboring of already machined jaws necessary

Visual safety devices

Maximum operating safety

Excellent clamping force/torque ratio

Perfect use of the machine performance

Straight serrated base jaws GBK are compatible to system “R“ (Reishauer)

Flexible clamping of small and large workpieces

Ergonomic, light safety spanner wrench

Ensures easy operation

Very easy handling

Optimal operator convenience

All functional parts are ground and hardened

High run-out and jaw change repeat accuracy

Options and special information

The manual chucks with jaw quick-change system ROTA-G ensure optimum results in workpiece clamping, especially on cycle-controlled lathes. The wedge bar actuation system ensures high precision, run-out and repeat accuracy as well as the highest clamping forces.

The large chuck bore makes the machining of raw material with very large diameters possible. By using the quick-change system, no rework of jaws is necessary after jaw change.

Magnetic clamping plates

MAGNOS KEH plus

|

Control unit

SCHUNK SE & Co. KG

Magnetic clamping plates

Description

Modular control units with holding force regulation for magnetizing or demagnetizing of up to eight magnetic chucks.

Advantages – Your benefits

Expandable modular system

Depending on the control unit, up to eight magnetic chucks can be controlled

Various standard versions depending on the case of application

One control unit for all square pole plates with and without status display from SCHUNK

16-step holding force regulation

Allows clamping of thin workpieces and simplifies the alignment of heavier workpieces

Modularly constructed handheld remote control

Allows each magnetic chuck as well as its holding force regulation to be individually controlled

Display of the clamping status via LED

Increasing the safety by knowing whether the workpiece is clamped or released

Display of error codes via LCD display

In the case of malfunctions, the error cause can be found more quickly

Large selection of accessories

The control unit or the magnetic chucks can be quickly and easily adapted to new clamping tasks

Options and special information

Increased user comfort

The modularly designed SCHUNK MAGNOS KEH plus is suitable for all square pole plates from SCHUNK. Three basic versions for the control of one, two, four or eight magnetic chucks and a wide range of different cable and handheld remote controls are sufficient to cover all requirements.

Concerning the selection of a suitable connecting cable, both small magnetic clamping plates with 4-PIN connectors as well as large magnetic chucks with 7-PIN connectors can be actuated. Equipped with connectors, all cables can be quickly and easily exchanged if necessary.

It is also possible to assign vacant slots at any time with additional magnetic chucks. A 16-step holding force regulation process facilitates the alignment of the workpieces and allows for the clamping of thin components.

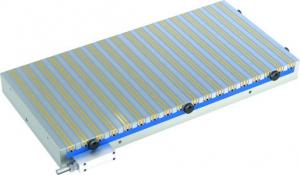

MAGNOS MFRS

|

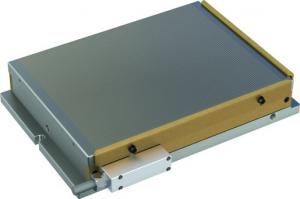

Magnetic clamping plate

SCHUNK SE & Co. KG

Magnetic clamping plates

Description

Magnetic chucks with extremely high holding forces for milling applications as an ideal clamping solution for powerful metal cutting processes with simultaneous 5-sided workpiece machining in a single set-up.

Field of application

3-axis standard machining center

4-axis vertical machining center

4-axis horizontal machining center

5-axis machining center

Advantages – Your benefits

5-sided workpiece machining in one set-up

Higher accuracy by setting up once and at best accessibility of the machine spindle

Even permanent magnetic clamping force over the entire workpiece

Low deformation and vibration clamping of the workpieces

Low vibration clamping

Improved surface finishes and significantly increased precision.

Deformation-free clamping

No deformation and inner forces in workpiece due to clamping forces

Patented status display

Secure clamping and maximum process reliability

Control unit compatible with machine control system

Can also be used in automated applications

Mono-block design

Compact and robust design with high rigidity

The modular principle

Depending on the application or type of machine, the magnetic can be combined or extended in accordance with the modular design principle

Clamping within a few seconds

Shortest possible set-up times and a resulting increase in productivity

Unique energy supply for MAG/DEMAG process

Energy-efficient and secure clamping of the workpieces

Large selection of accessories

Optimal adaptation possibilities in the respective clamping task

Options and special information

Three square pole sizes for highly individual workpiece clamping

The magnetic chucks are each available in three different square pole dimensions. This offers the possibility of individually adjusting the magnetic chuck to its specific clamping task within a larger range of clamping tasks. The decisive factors are the thickness, weight, surface, geometry, and dimensions of the workpiece being machined.

Magnetic chuck type MFRS-A1

MFRS-A1 magnetic chucks with a high compact performance of acting magnetic force are generally sufficient for 80% of all applications.

Magnetic chuck type MFRS-A2

MFRS-A2 plates have an even higher density of magnetic field penetrating into the workpiece. These are used primarily for workpieces with very uneven surfaces (die-cast and forged parts) and thus a larger air gap, as more magnetic field lines stay in contact with the workpiece.

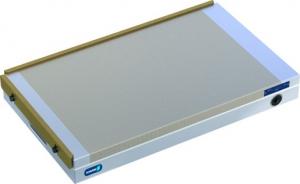

MAGNOS MSC-PM15

|

Magnetic clamping plate

SCHUNK SE & Co. KG

Magnetic clamping plates

Description

Manual permanent magnetic chucks with parallel pole pitch for clamping of small workpieces and thin parts for precision grinding work on grinding machines.

Field of application

Surface grinding machines

Jig milling machines

Profile grinding machines

Advantages – Your benefits

Even permanent magnetic clamping force over the entire workpiece

Low deformation and vibration clamping of the workpieces

Low vibration clamping

Improved surface finishes and significantly increased precision.

Deformation-free clamping

No deformation and inner forces in workpiece due to clamping forces

Mono-block design

Compact and robust design with high rigidity

Clamping within a few seconds

Shortest possible set-up times and a resulting increase in productivity

Low magnetic field height

Prevents a magnetization of the machining tools

Options and special information

The manual MAGNOS MSC-PM15 magnetic chucks are actuated via a lateral hexagon socket connection. The magnetic clamping force can be continuously adjusted. The low magnetic field height prevents magnetization in the machining tools, allowing very thin and small parts to be processed.

MAGNOS MSC-PM35

|

Magnetic clamping plate

SCHUNK SE & Co. KG

Magnetic clamping plates

Description

Manual magnetic chucks with radial pole pitch for machining rings and disks on cylindrical grinding machines.

Field of application

Radial pole Technology

Advantages – Your benefits

Even permanent magnetic clamping force over the entire workpiece

Low deformation and vibration clamping of the workpieces

Low vibration clamping

Improved surface finishes and significantly increased precision.

Deformation-free clamping

No deformation and inner forces in workpiece due to clamping forces

Mono-block design

Compact and robust design with high rigidity

Clamping within a few seconds

Shortest possible set-up times and a resulting increase in productivity

Low magnetic field height

Prevents a magnetization of the machining tools

MAGNOS MSC-PM60D

|

Magnetic clamping plate

SCHUNK SE & Co. KG

Magnetic clamping plates

Description

Electro-permanent magnetic chucks with larger parallel pole pitch for clamping of medium-sized and large workpieces on grinding machines.

Field of application

Surface grinding machines

Jig milling machines

Profile grinding machines

Advantages – Your benefits

Even permanent magnetic clamping force over the entire workpiece

Low deformation and vibration clamping of the workpieces

Low vibration clamping

Improved surface finishes and significantly increased precision.

Deformation-free clamping

No deformation and inner forces in workpiece due to clamping forces

Mono-block design

Compact and robust design with high rigidity

Clamping within a few seconds

Shortest possible set-up times and a resulting increase in productivity

Low magnetic field height

Prevents a magnetization of the machining tools

Options and special information

MAGNOS MSC-PM 60 magnetic chucks are connected to the control unit via a lateral connection plug. Due to their large pole pitch, large workpieces can be securely clamped without the magnetic chucks becoming significantly hot.

MAGNOS MSC-PM62F

|

Magnetic clamping plate

SCHUNK SE & Co. KG

Magnetic clamping plates

Description

Electro-permanent magnetic chucks with fine parallel pole pitch for clamping of small workpieces and thin parts for precision grinding works on grinding machines.

Field of application

Surface grinding machines

Jig milling machines

Profile grinding machines

Advantages – Your benefits

Even permanent magnetic clamping force over the entire workpiece

Low deformation and vibration clamping of the workpieces

Low vibration clamping

Improved surface finishes and significantly increased precision.

Deformation-free clamping

No deformation and inner forces in workpiece due to clamping forces

Mono-block design

Compact and robust design with high rigidity

Clamping within a few seconds

Shortest possible set-up times and a resulting increase in productivity

Low magnetic field height

Prevents a magnetization of the machining tools

Options and special information

MAGNOS MSC-PM 62 magnetic chucks are connected to the control unit via a lateral connection plug. The low magnetic field height prevents magnetization in the machining tools, allowing very thin and small parts to be processed.

Lathe chucks, pneumatically operated

ROTA TB2

|

Lathe chuck, pneumatically operated

SCHUNK SE & Co. KG

Lathe chucks, pneumatically operated

Description

Pneumatic 3-jaw chuck with a large through hole

Field of application

on conventional lathes

on cycle-controlled lathes

on drill / boring machines

on welding systems

on special machines

Advantages – Your benefits

Precision wedge hook pneumatic power chuck for highest quality demands

Allows excellent machining processes

Very large through-hole

Machining of all standard pipe diameters

High efficiency of the wedge hook system

Process-reliable clamping due to high clamping forces

Optimized lubrication system

Consistently high clamping forces are ensured

Monitoring the opening and closing process

Process-reliable operation of the lathe chuck

Fast ventilation of the pressure chambers

Shorter process times

Pneumatic cylinder integrated in the chuck

Especially suitable for lathes without a hydraulic cylinder

Sealed guideways

Optimum protection against coolant and chips

Air supply via distributor ring

Very simple control of the chuck

High clamping forces at system pressure

Ensure process reliability during machining

Low noise generation

Increased health protection

Corrosion-resistant functional components are hardened and ground on all sides

Ensures a long service life

Options and special information

Powerhouse for machining rods and pipes

SCHUNK’s ROTA TB2 pneumatic power chuck sets a new standard in machining of rods and pipes for the oil industry as well as the mining and construction sectors. Despite the compact outer dimensions, for example, the ROTA TB2 has an extremely large through-hole of up to 560 mm.

With air pressure of 6 bar it is already possible to achieve very high clamping forces of up to 280 kN, which can easily be adapted to the particular task. An anti-corrosive coating applied to the most important functional components of the SCHUNK ROTA TB2 significantly increases the service life.

ROTA TB2-LH

|

Lathe chuck, pneumatically operated

SCHUNK SE & Co. KG

Lathe chucks, pneumatically operated

Description

Pneumatic, 3-jaw, front-end chuck with fast and clamping strokes and a large through-hole for O.D. clamping.

Field of application

on conventional lathes

on cycle-controlled lathes

on drill / boring machines

on welding systems

on special machines

Advantages – Your benefits

Precision wedge hook pneumatic power chuck for highest quality demands

Allows excellent machining processes

Very large through-hole

Machining of all standard pipe diameters

High efficiency of the wedge hook system

Process-reliable clamping due to high clamping forces

Visual safety devices

Maximum operating safety

Optimized lubrication system

Consistently high clamping forces are ensured

Monitoring the opening and closing process

Process-reliable operation of the lathe chuck

Fast ventilation of the pressure chambers

Shorter process times

Pneumatic cylinder integrated in the chuck

Especially suitable for lathes without a hydraulic cylinder

Sealed guideways

Optimum protection against coolant and chips

Air supply via distributor ring

Very simple control of the chuck

High clamping forces at system pressure

Ensure process reliability during machining

Low noise generation

Increased health protection

Corrosion-resistant functional components are hardened and ground on all sides

Ensures a long service life

Options and special information

Powerhouse for machining rods and pipes

SCHUNK’s pneumatic power chuck ROTA TB2-LH sets a new standard in the machining of rods and pipes for the oil industry as well as the mining and construction sectors. Despite the compact external dimensions, the ROTA TB2-LH has an extremely large through-hole of up to 560 mm.

With an air pressure of 6 bar it is possible to achieve very high clamping forces of up to 240 kN, which can be easily adapted to the particular task. An anti-corrosive coating applied to the most important functional components of the SCHUNK ROTA TB2-LH significantly increases the service life.

Loading ...