I've only machined a couple of small pieces in Delrin, but it's fantastic to usefast, quiet, gigantic chips that are easy to clean and pick up. Love it!

Siemens

Forum

Digital Industries, Motion Control, Machine Tool Systems

Thread: PM-45 CNC Conversion (RF45)

Results 581 to 600 of 874

-

03-19-2013, 04:01 PM #581

Registered

Registered

- Join Date

- Jan 2012

- Posts

- 469

-

03-20-2013, 10:08 PM #582

Registered

Registered

- Join Date

- Aug 2006

- Posts

- 673

Hi, great thread!

I just received my PM45 today, and am looking to convert it to CNC as well. Do you still have the CAD models? I'd love to get my hands on them, it would save me a ton of time measuring mine up

-

03-21-2013, 03:11 AM #583David589 Guest

Could be worth trying lower RPM as well, for hopefully less heat and tendency for chips to stick/weld themselves to the tool?

-

03-22-2013, 12:31 AM #584

Registered

Registered

- Join Date

- Jun 2011

- Posts

- 0

Yeah as Jess said there earlier and rlockwood too, I too use flood coolant all the time in my BF20 which hasn't even half the capacity of your build and even yesterday I was using a four flute endmill to profile cut a part out of a larger stock piece (and also without widening the cut) so basically it was similar to an awfully long slot with curves and corners....and yes as was suggested earlier a two flute would definitely allow for easier chipload removal...in my humble experience with a smaller mill and lower capacity I can still achieve pretty good high end cutting speeds with flood coolant. .....

Eoin

-

03-23-2013, 06:47 AM #585

Pretty sweet compressor man. I love how silent it is. For others with a traditional 5HP 2 stage compressor if you move the intake to say out side or even in the attic and put a large filter like the old school cheap ones on muscle cars it really drops the noise a lot. You would be surprised how much noise is actually coming from the inlet of the pump.

I love your expression after you hit the vise. I say the same stuff. I haven't hit the vise yet, but their are times it sure is close.Jeremiah

PM45 CNC Build in Progress

-

03-26-2013, 05:00 AM #586

Gold Member

Gold Member

- Join Date

- Feb 2010

- Posts

- 3447

-

03-26-2013, 10:58 AM #587

Gold Member

Gold Member

- Join Date

- Feb 2010

- Posts

- 3447

Ugh! Amazing.. where to begin.. Awesome car, sweet mill and conversion, amazing gun (btw i'd love to get into that, sport shooting). Gotta give credit, where its due. Attention to detail and quality, very nice job. You mentioned where to go local for tooling. Right in Auburn, I've been numerous times to http://www.1asi.com/.

Application Specialties. They supply a lot of the Boeing suppliers and shops in the Puget Sound. Really nice guys. Be warned you will leave about 100 pounds heavier with free brochures, and tool magazines. Some of there stuff, is top quality and really out of the price range of the hobbyist. There economy endmills, are still probably better than anything youll find from little machine shop though. They are really well priced also for the little stuff. They also resharpen bit for cheap, and can pretty much get ahold of anything you need. Anyways, amazing job keep up the good work. I'm in the process of getting my little machine shop X3 going, so im sure in the future youll see me asking for help haha. Anything you need feel free to message me. Nice to know people locally!

Can't wait for more updates!

-

03-26-2013, 06:09 PM #588

Member

Member

- Join Date

- Jul 2006

- Posts

- 525

-

04-07-2013, 07:01 AM #589

Registered

Registered

- Join Date

- Feb 2011

- Posts

- 605

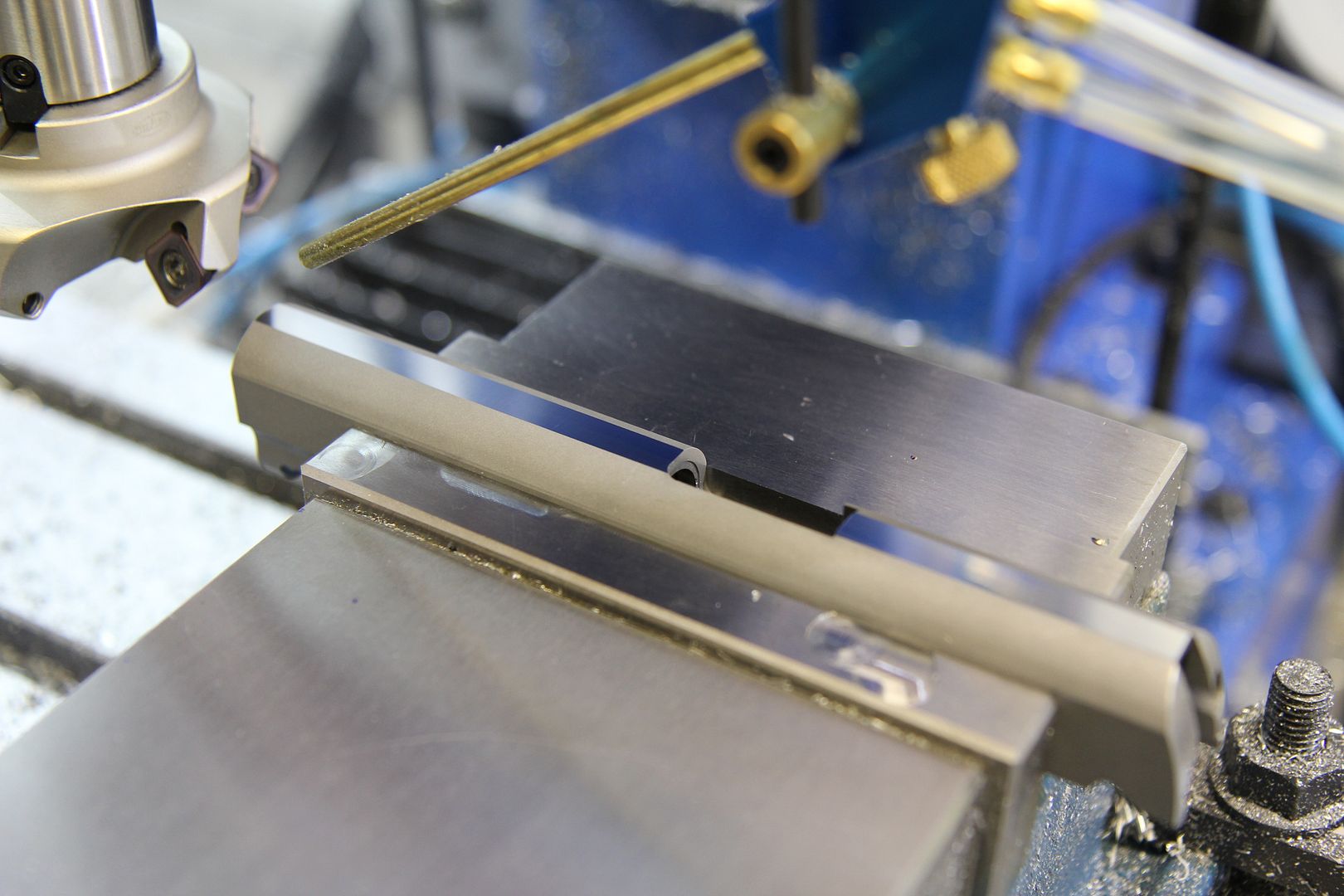

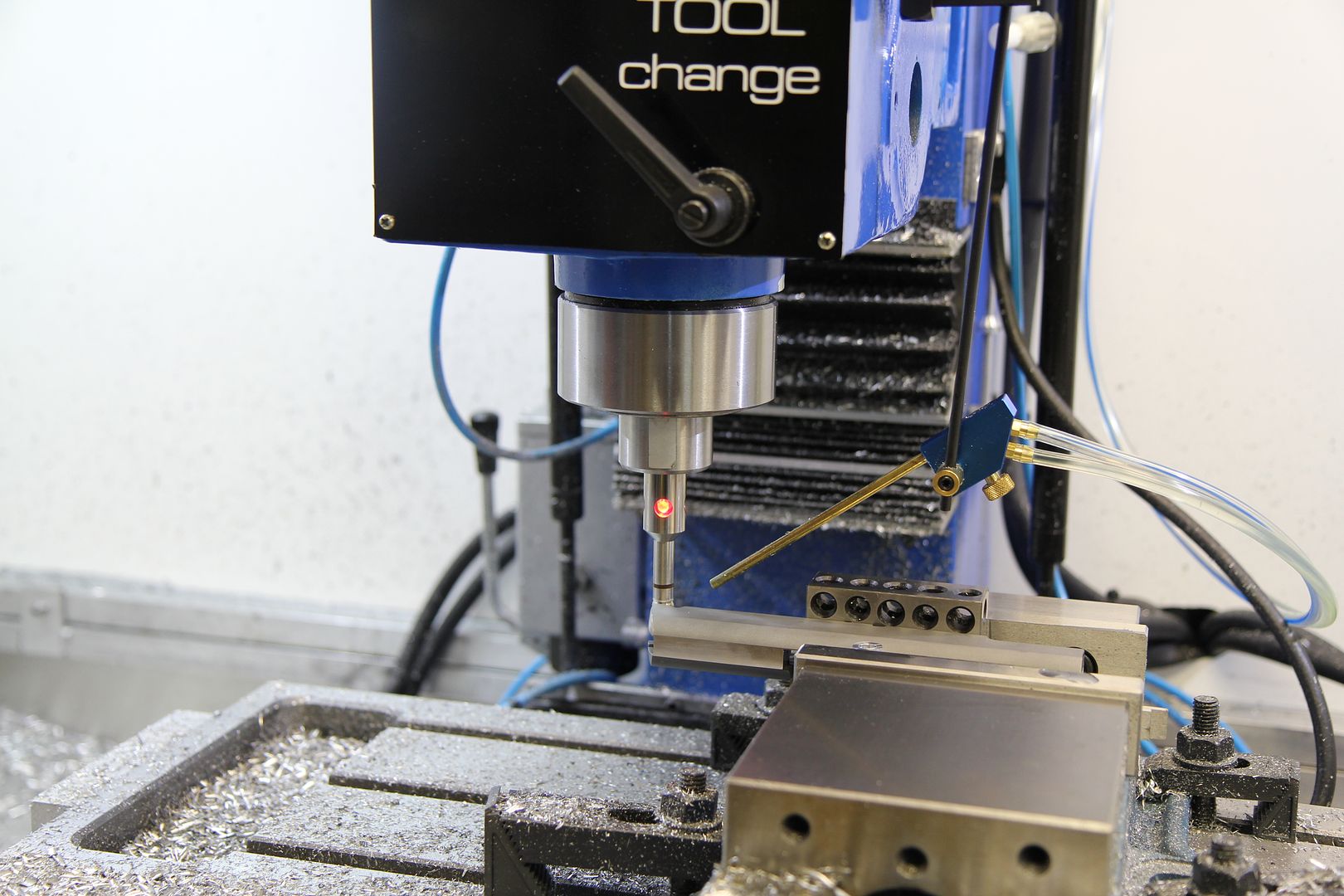

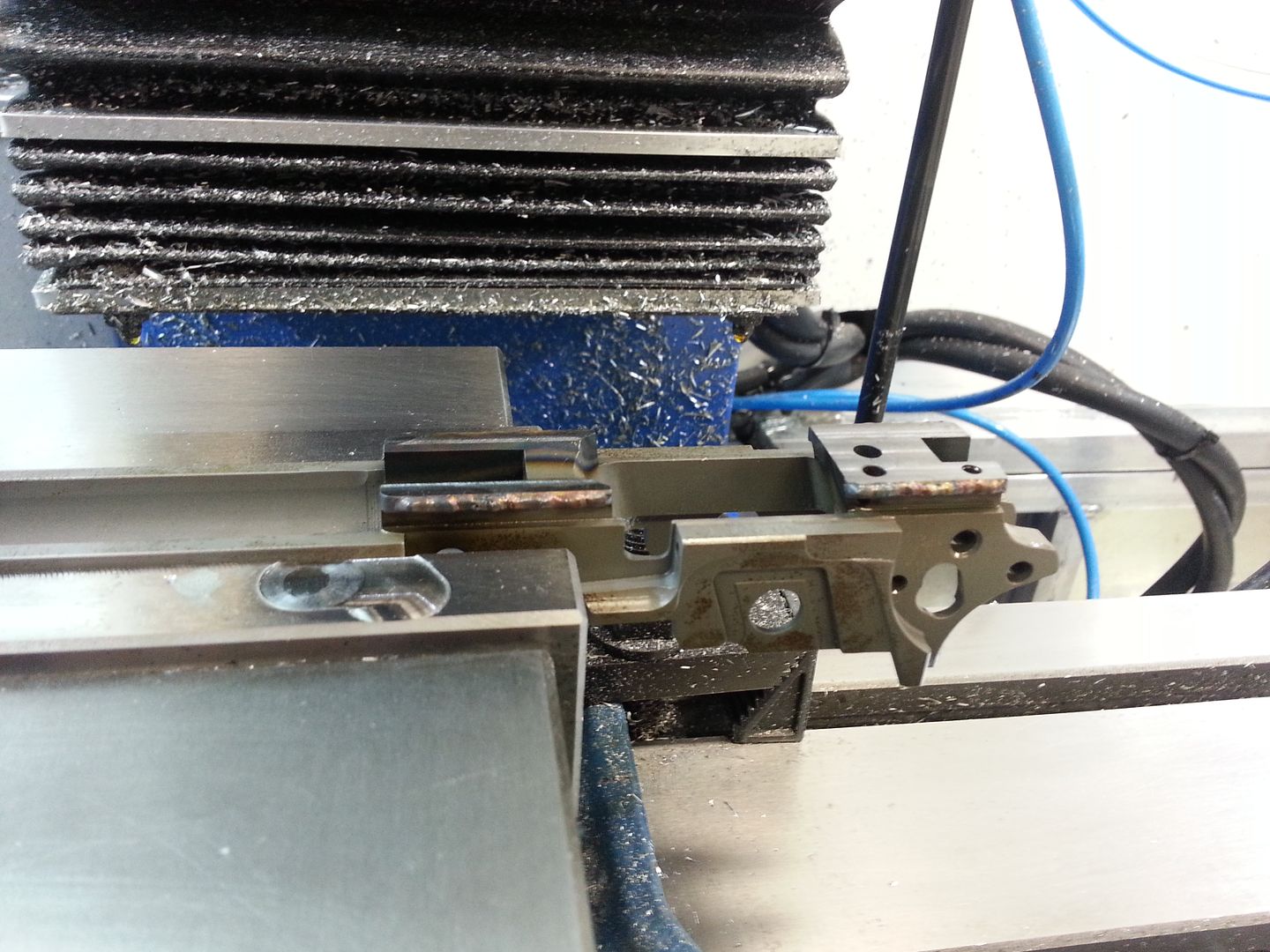

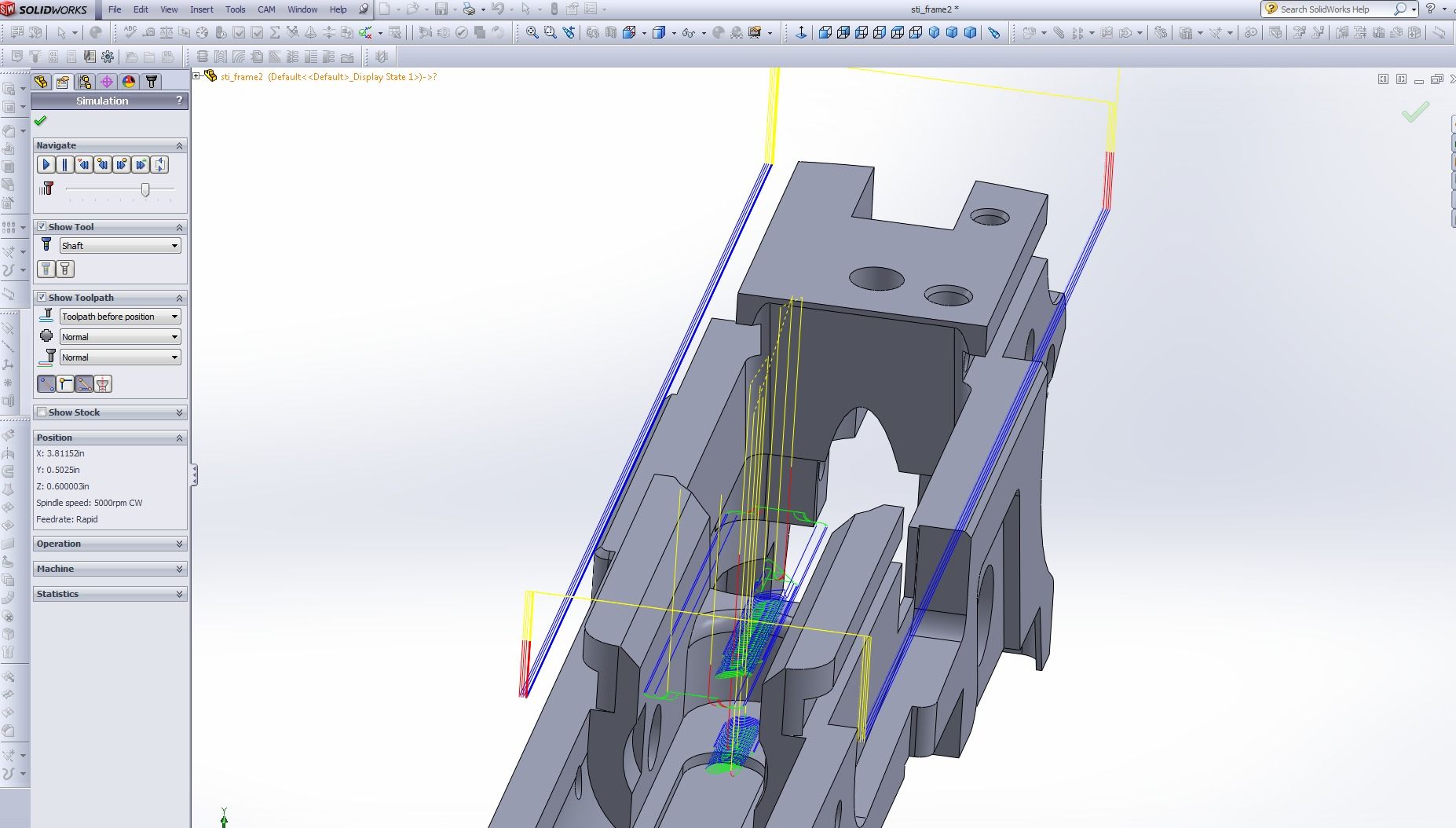

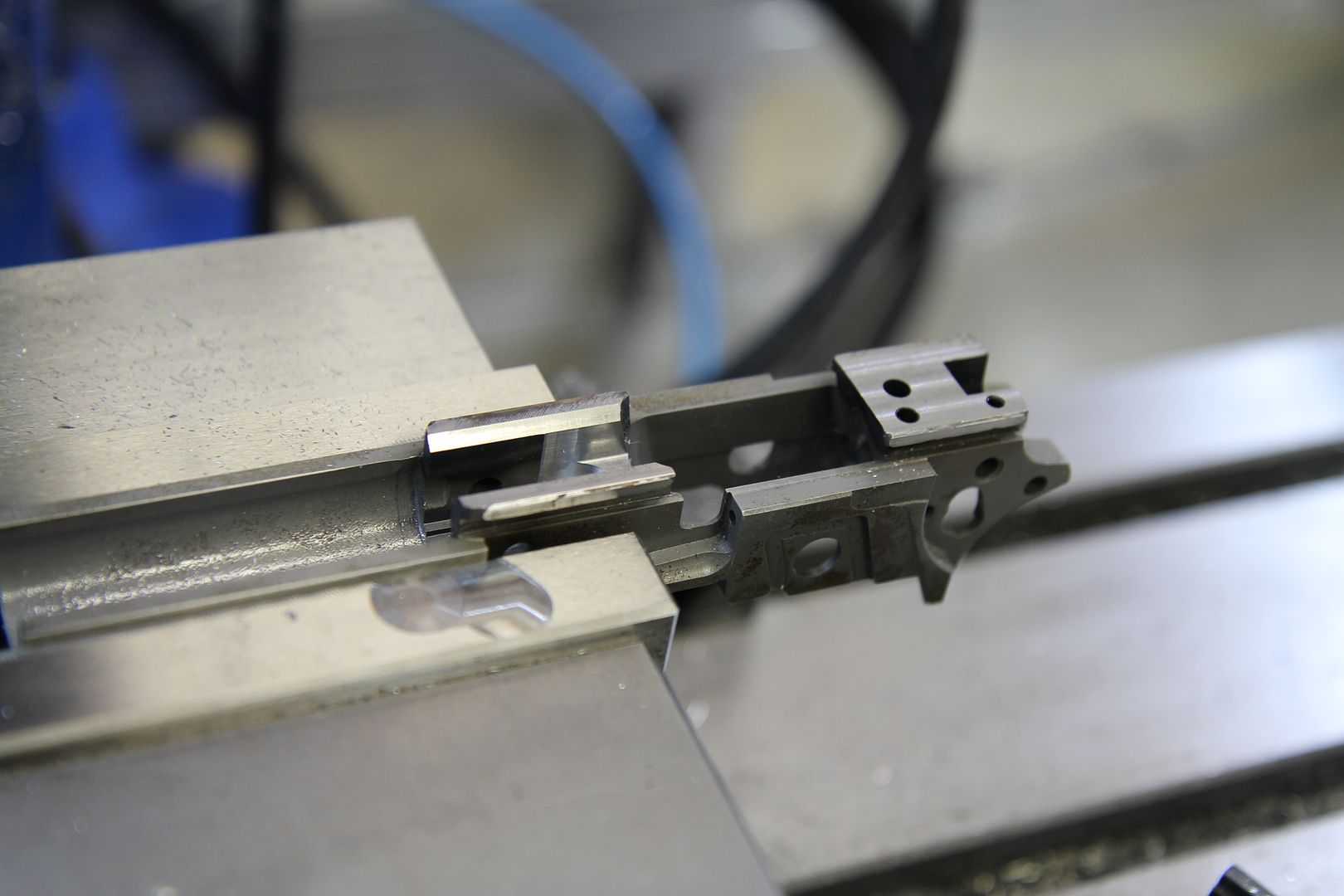

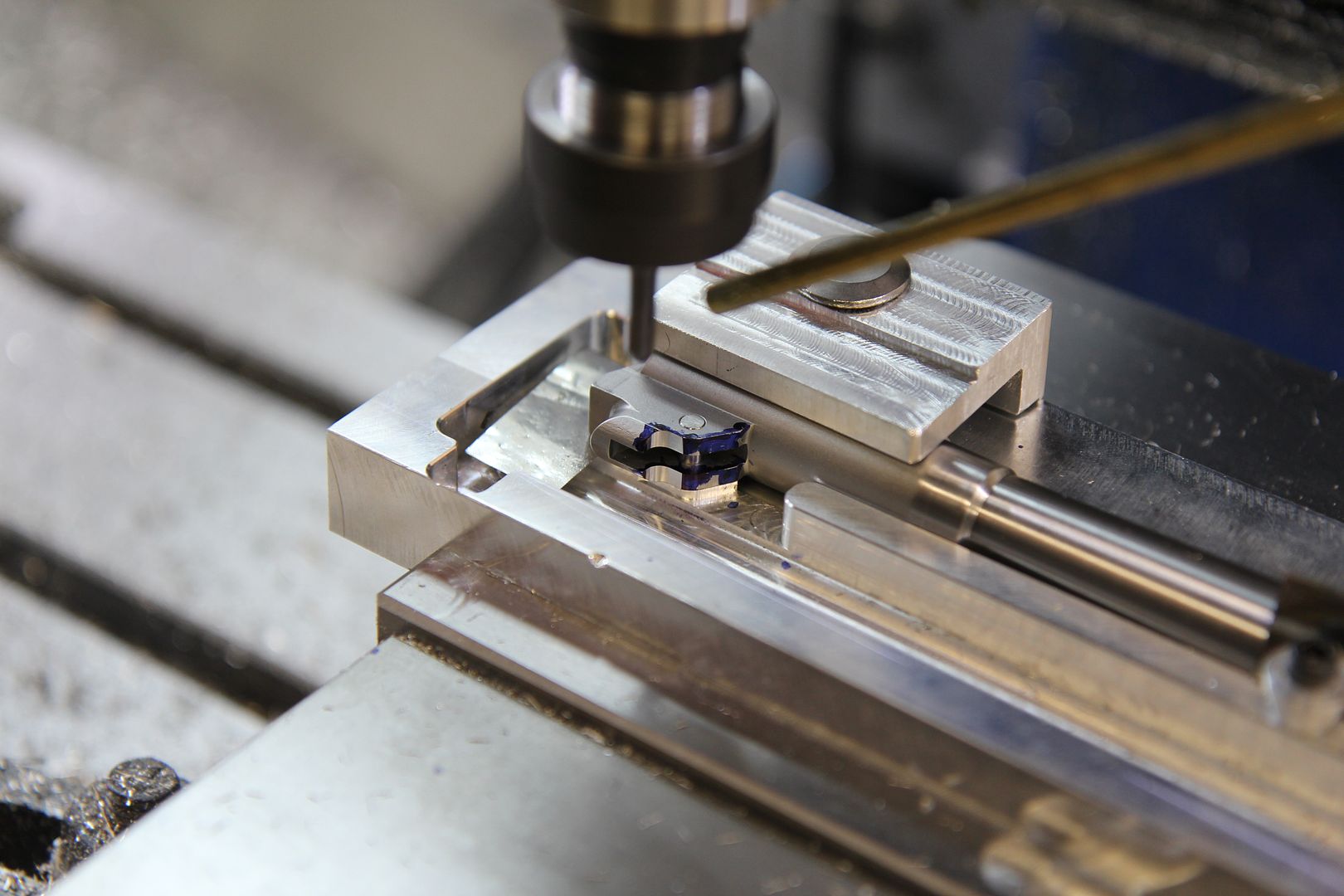

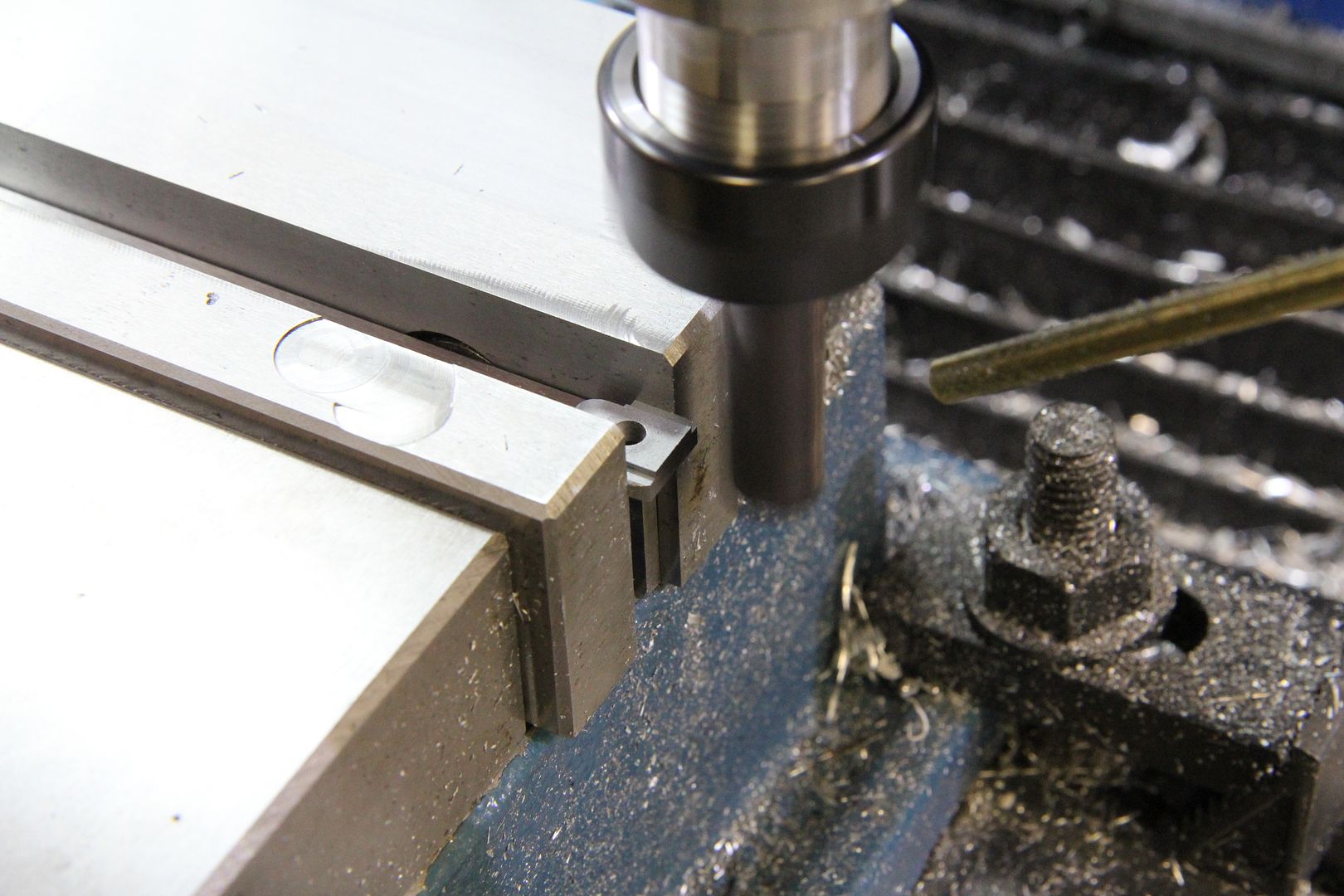

Haven't mounted the new vises, but I did make a little progress on my new gun I'm building. I did a poor job fitting the rails the first time, so I weld them back up with the TIG and programmed the toolpaths instead of doing it with MDI and no plan like before.

Welded up and ready to go.

Toolpaths

Cutting

STI 2011 Frame Fitting - CNC - YouTubePM-45 CNC conversion built/run/sold.

-

04-27-2013, 06:00 PM #590

- Join Date

- Feb 2013

- Posts

- 38

Wow, great job on the machine and what you're doing. I found this thread from Straightup_OG's on the Bverse. Thanks a lot for all the detailed description and photos. Very helpful for a newb like me.

Kevin

-

04-27-2013, 07:04 PM #591

Registered

Registered

- Join Date

- Feb 2011

- Posts

- 605

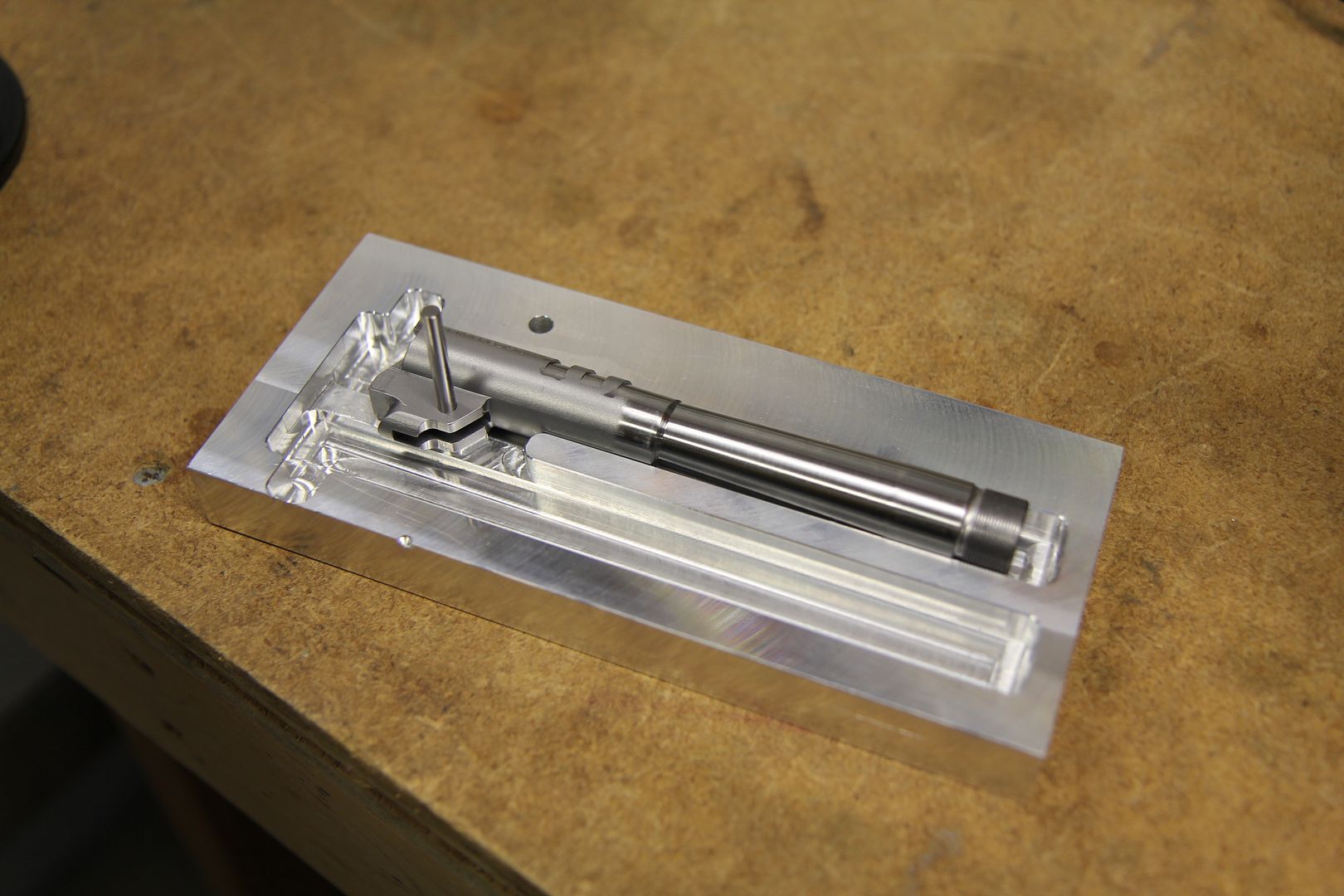

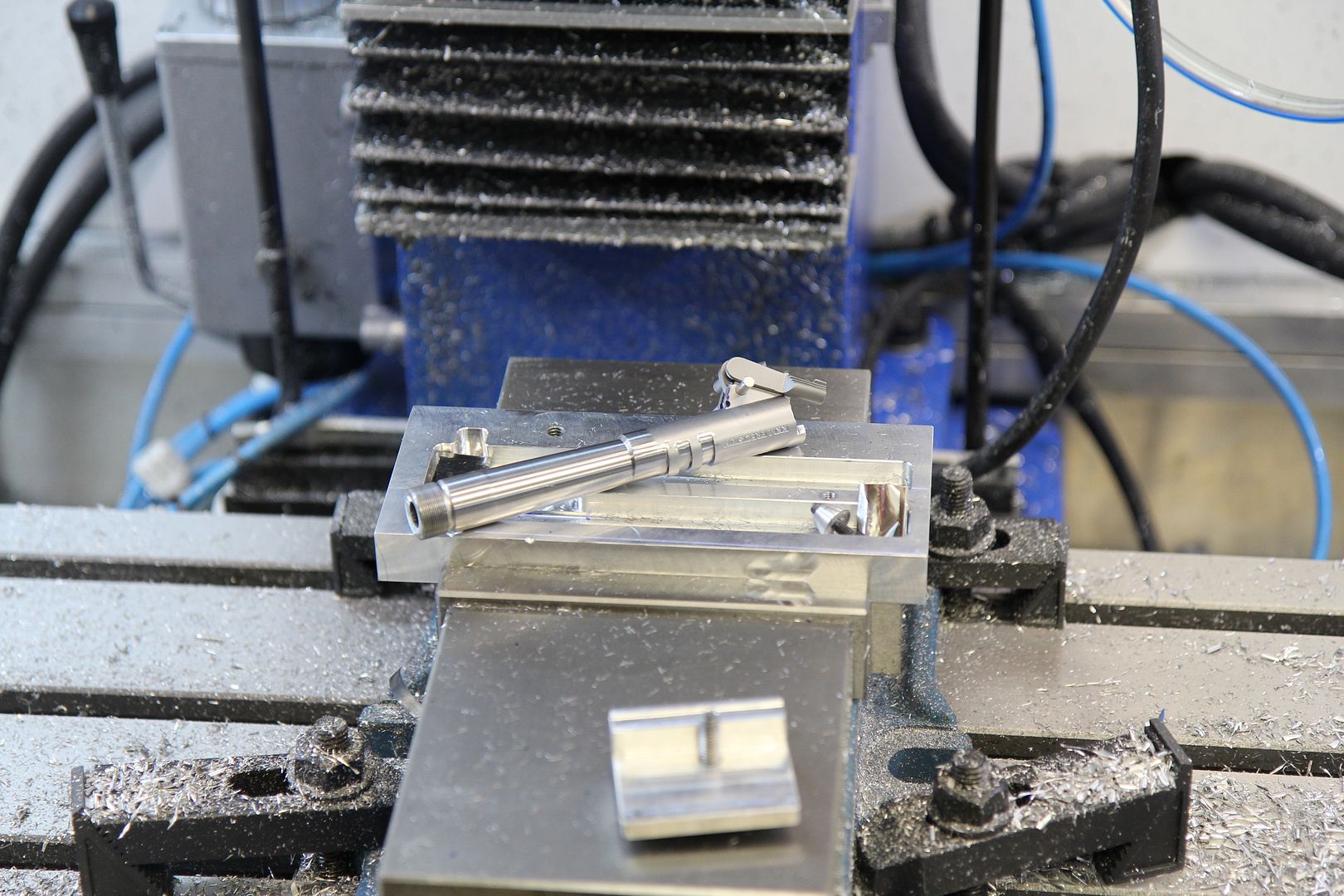

Thanks. Heading out to build a barrel holding fixture and then profile cut the lower lugs.

-

04-28-2013, 03:54 AM #592

Registered

Registered

- Join Date

- Apr 2013

- Posts

- 20

Nice thread. 2011's are fun.

-

04-28-2013, 05:40 PM #593

Registered

Registered

- Join Date

- Feb 2011

- Posts

- 605

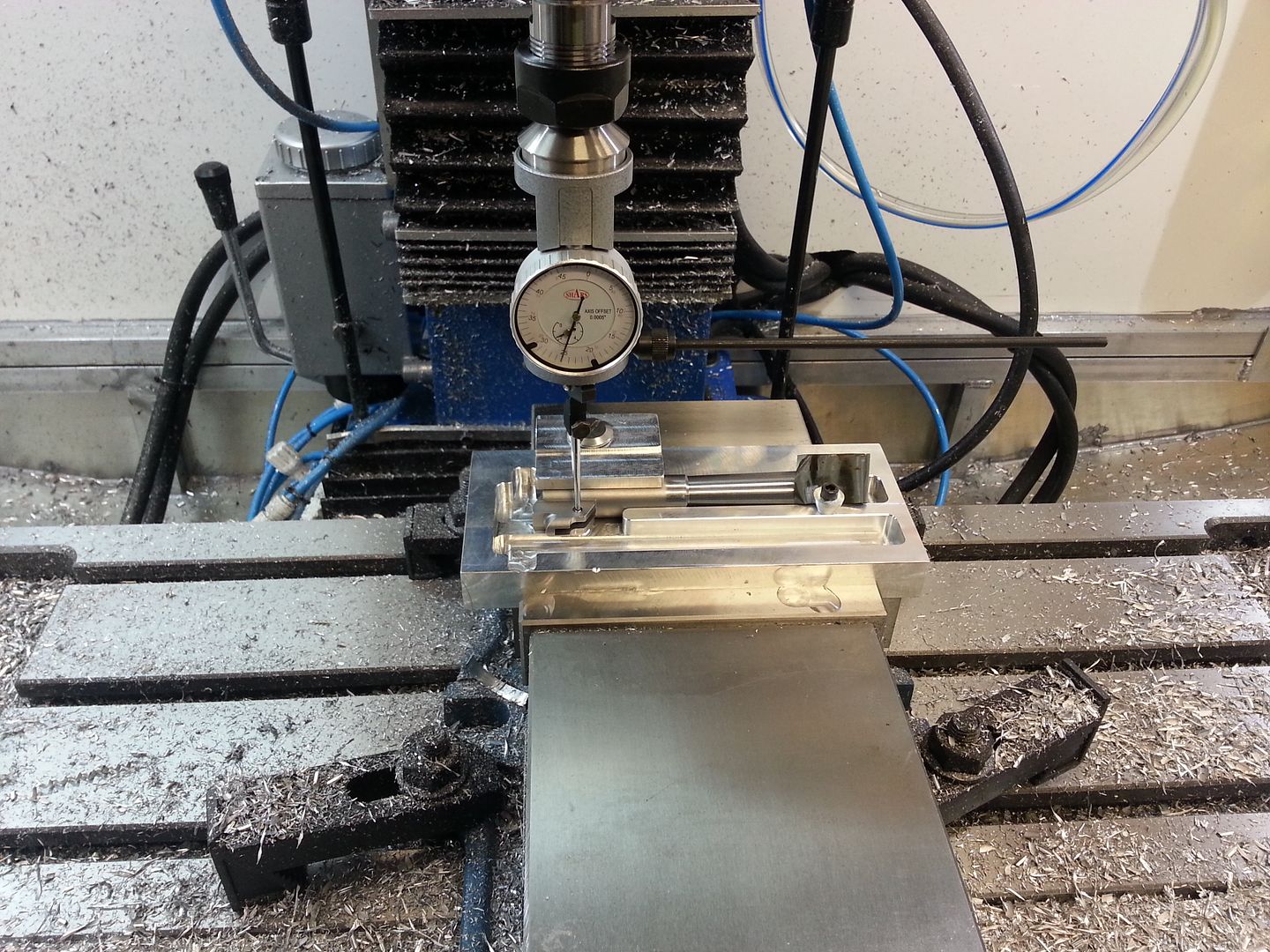

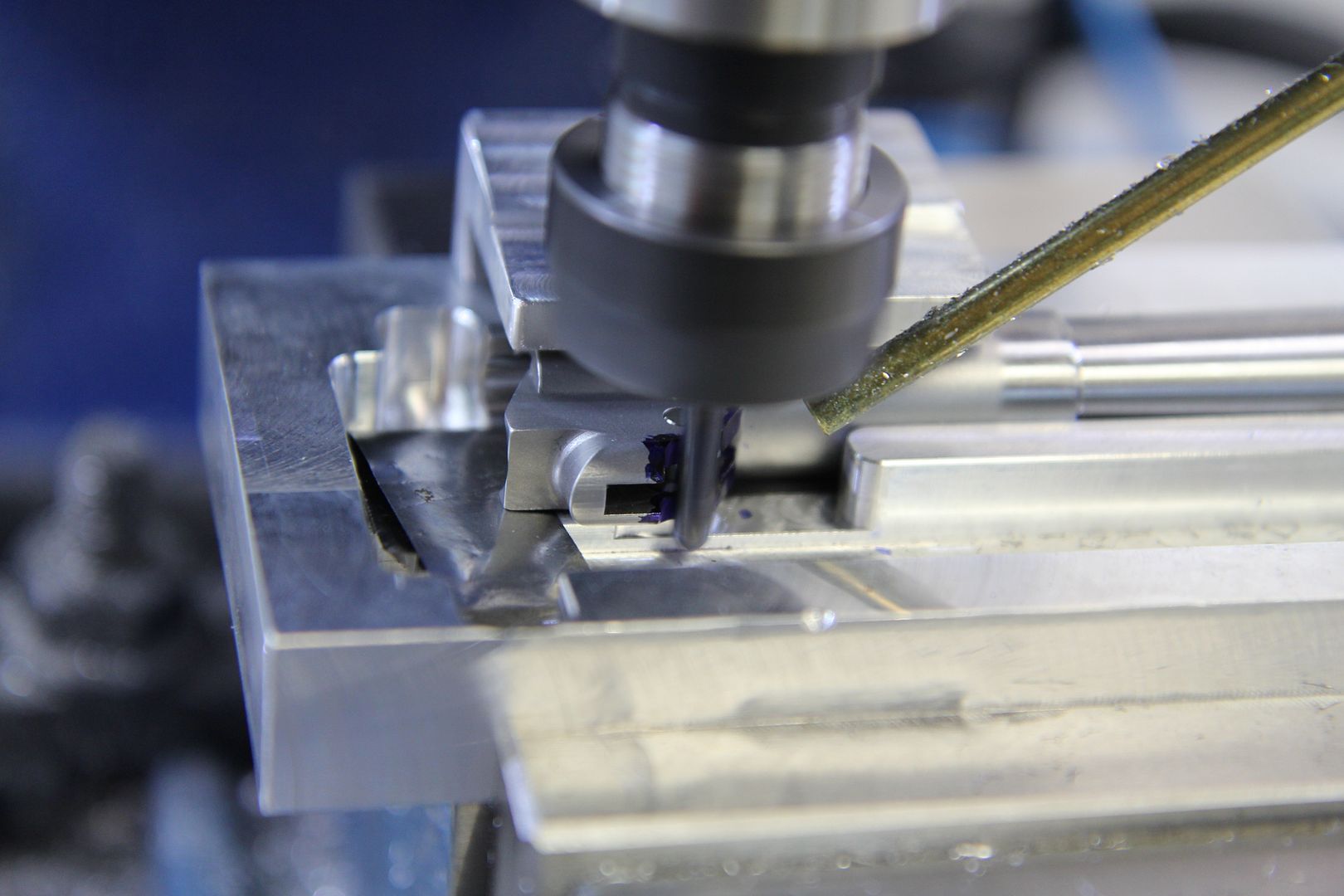

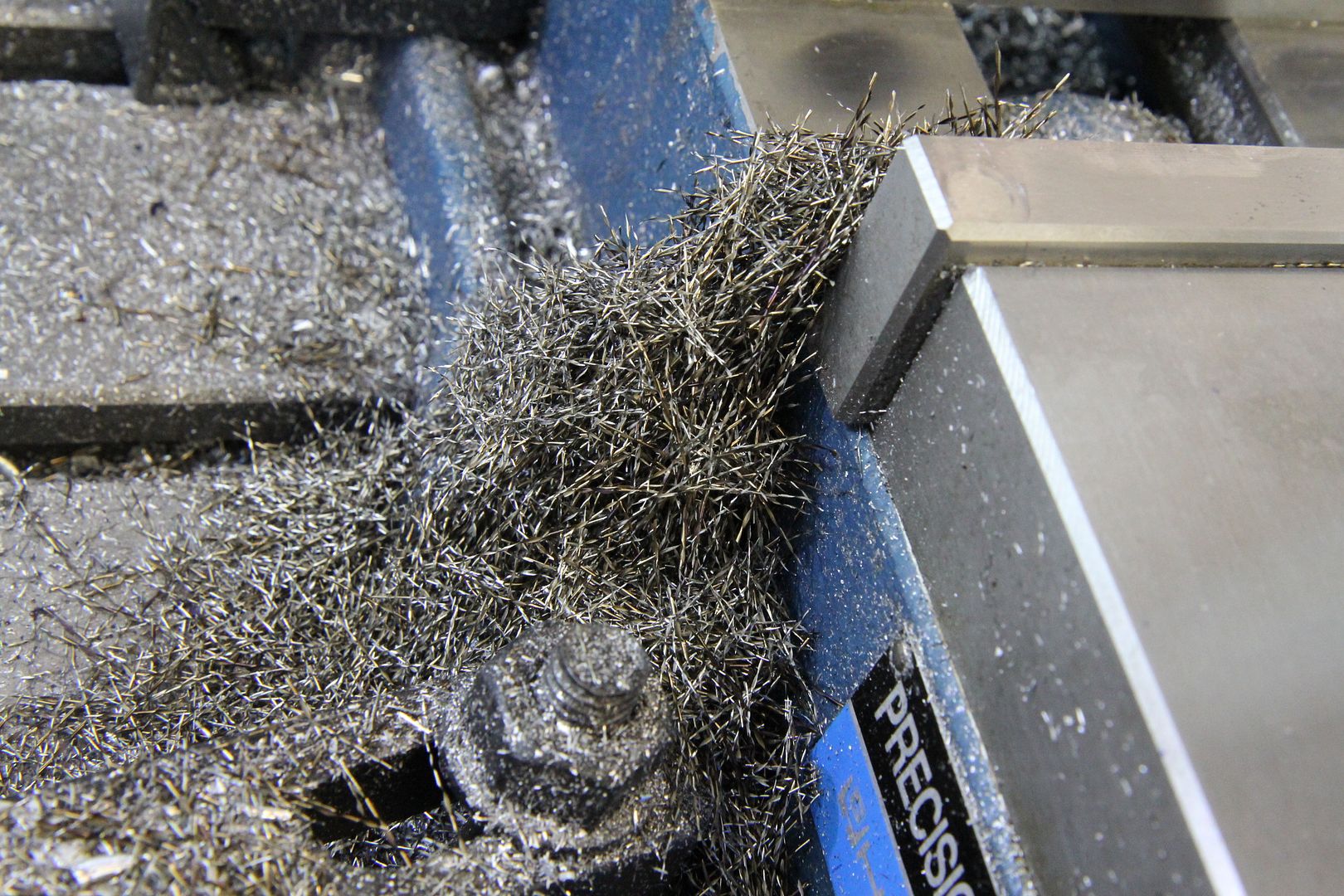

Fixture all machined. My spindle has the random dip in speed, who knows why, but you can hear it happen in the video. Did some slotting with a 1/2" 3 flute, went well until the very end of the operation where one flute starts to clog while ramping down into the 2nd level. I just let it go. I guess slotting is really a 2 flute deal. But it did run nice at .20" DOC, 6800 RPM and 42 IPM. Next time I slot I'll move to 2 flute and up the DOC to .25".

I bought a couple CAT40 ER20 holders and some pull studs for Haas and Hurco. That gives me a few of my own tools for testing machines!

Making a 1911 Barrel Holding Fixture - YouTube

PM-45 CNC conversion built/run/sold.

PM-45 CNC conversion built/run/sold.

-

04-29-2013, 01:00 PM #594

Gold Member

Gold Member

- Join Date

- Feb 2010

- Posts

- 3447

VERY nice!!

-

05-05-2013, 07:41 PM #595

Registered

Registered

- Join Date

- Feb 2011

- Posts

- 605

I'll add some text later....

1911 CNC lower lug cutting - YouTubePM-45 CNC conversion built/run/sold.

-

05-05-2013, 08:00 PM #596

Registered

Registered

- Join Date

- Feb 2011

- Posts

- 605

-

05-05-2013, 08:04 PM #597

Registered

Registered

- Join Date

- Feb 2011

- Posts

- 605

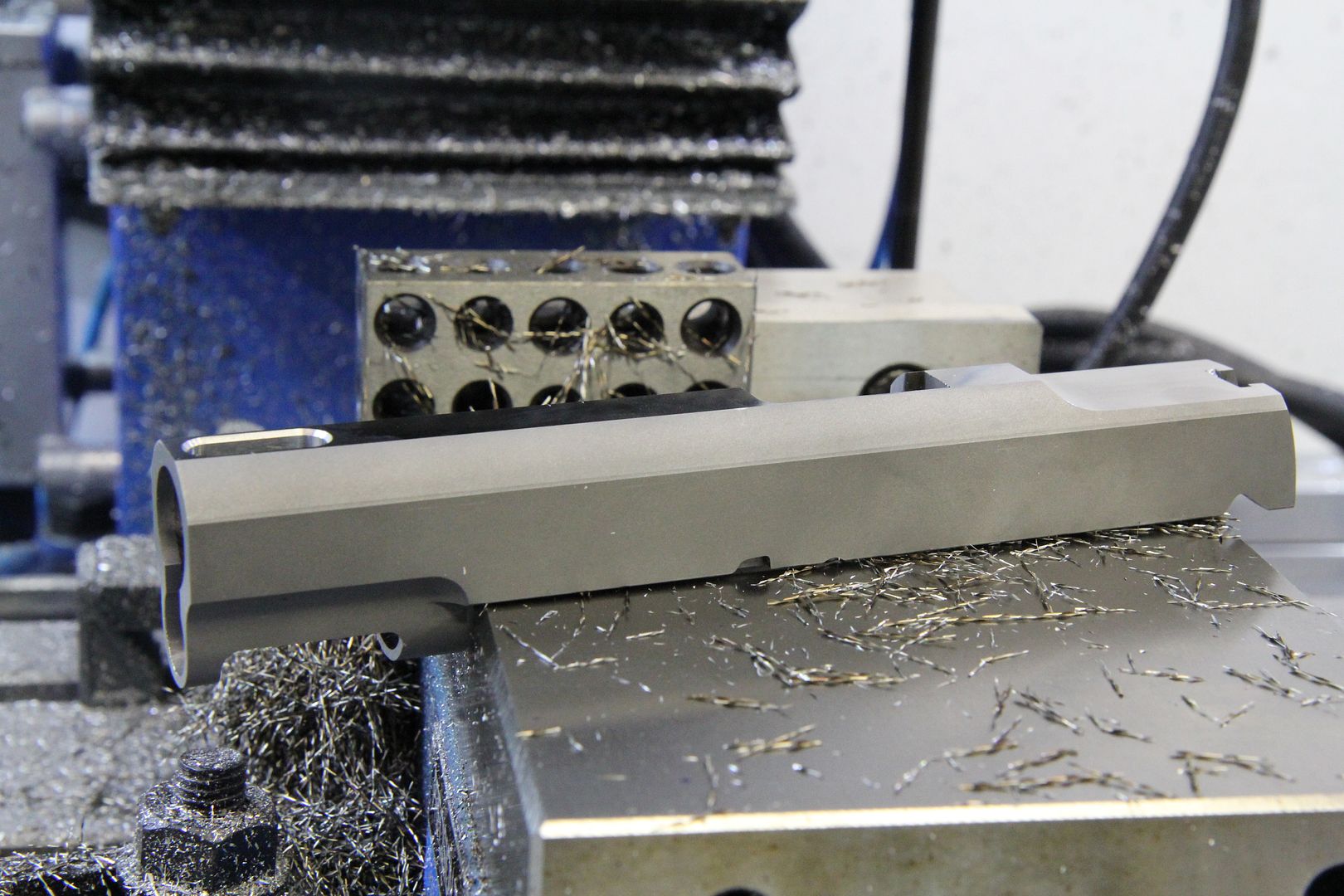

More

*

*

*

*

*

*

Open Gun Slide Work Part 1 - CNC 1911 Slide Lightening - YouTubePM-45 CNC conversion built/run/sold.

-

05-06-2013, 02:34 AM #598

Registered

Registered

- Join Date

- Apr 2013

- Posts

- 20

Niiiiiice.

Which red dot are you putting on there?

-

05-06-2013, 03:02 AM #599

Plastic

Plastic

- Join Date

- May 2013

- Posts

- 0

Anything you need feel free to message me. Nice to know people locally!

-

05-06-2013, 03:38 AM #600

Registered

Registered

- Join Date

- Feb 2011

- Posts

- 605

PM-45 CNC conversion built/run/sold.

Similar Threads

-

Starting another DMM conversion, IH RF45 clone

By ayorba in forum Dmm TechnologyReplies: 0Last Post: 06-08-2014, 02:36 AM -

HM45 Conversion (Yes another RF45 clone)

By slipery in forum Benchtop MachinesReplies: 10Last Post: 12-19-2011, 12:07 AM -

Am I Looking for NOISE trouble (RF45 Conversion)

By Bird_E in forum CNC Machine Related ElectronicsReplies: 6Last Post: 03-30-2011, 07:37 PM -

AC Servo on RF45 Conversion help

By Maglin in forum Servo Motors / DrivesReplies: 5Last Post: 02-23-2011, 03:57 PM -

RF45 clone CNC conversion

By GMitchell in forum Uncategorised MetalWorking MachinesReplies: 9Last Post: 09-08-2009, 05:50 AM

Reply With Quote

Reply With Quote