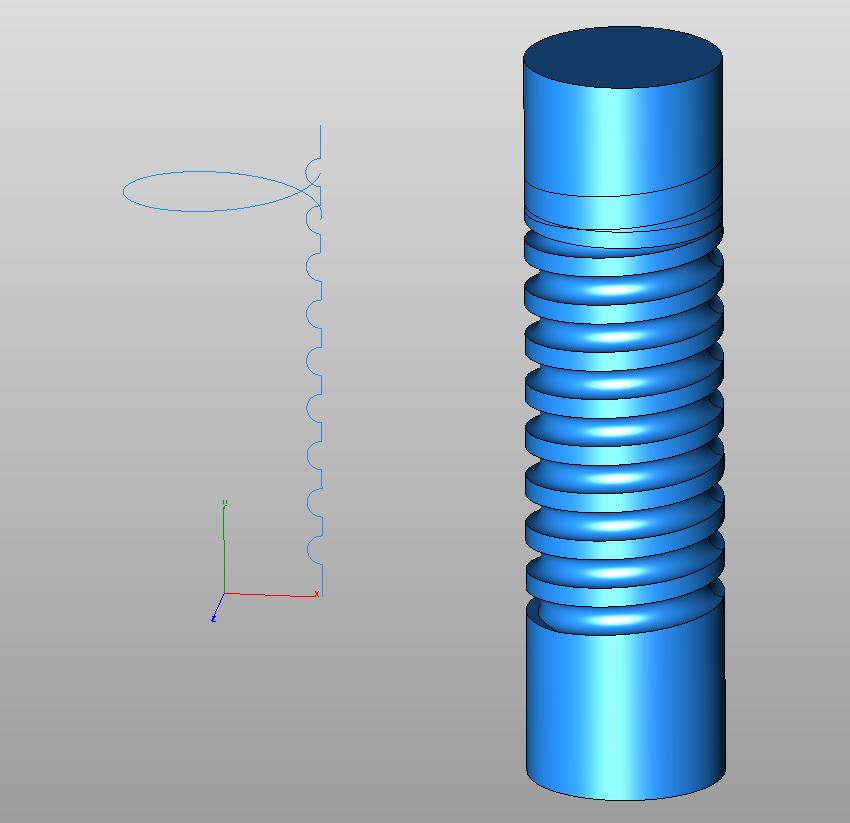

i think i have threading down. create a cylinder, wrap a helix around it, then create a "cutting tool" wedge (3 lines making triangle), trim off excess if need be, join the 3 lines as one, move point of triangle to some point on radius of cylinder (this is depth of cut), then do a one rail sweep solid, then subtract the sweep from the cylinder. voila, threads. just not sure this is the easiest way, but it works.

this is cylinder of 0.25" dia x 1" long, 40tpi (0.0250 pitch) with wedge cutter of 60 degrees. not exactly sure yet if what i did meets any std spec, but at least now i know how to cut threads.

just a note for Punch!, a threading tool would be nice. make helix, click threading tool, type in params (pitch, depth, angle, direction of cut), then, cut.

Attachment 217926

ray traced with metal camera, and a point light source. not bad.

TDM Systems

Forum

Digital. Experienced. Powerful. - 100% Tool Management

Thread: Threading

Results 1 to 9 of 9

-

01-09-2014, 07:59 PM #1Registered

- Join Date

- Jan 2006

- Posts

- 93

Threading

-

01-09-2014, 09:13 PM #2Member

- Join Date

- Sep 2012

- Posts

- 1195

Viacad is a little less robust for threading than other applications, which often have a built in thread tool. It works fine, but no matter which way you choose to do it, threads just take a bit more time.

I usually prefer to stay in 2d as long as possible for most operations, but this one is more of a toss up and I often do it differently depending on the needed parts. One way you could also try for the sake of learning more tools is you can create the 2d profile of the thread on one side only, do a linear array to create the length of the threads, create a single helix of the corresponding dimensions (height of helix for one turn is the difference from thread to thread O.C.), the do a surface extrusion along the helix by selecting the full 2d profile of threads and extruding them around the helix. This will create a shaft of threads, but the ends will still be hollow. From there, you can cap them with cylinders or whatever else you may be integrating them to.

-

01-10-2014, 01:59 PM #3Registered

- Join Date

- Jul 2013

- Posts

- 32

This is excellent posting guys. A while back I was looking all over the web for how to do threads and there wasn't a lot to be found and here you are posting in exactly the application I'm using. In one of my projects, I may be needing to use very large but small number of threads to attach a couple of 3D printed items together.

-

01-10-2014, 05:27 PM #4Registered

- Join Date

- Jan 2006

- Posts

- 93

could you test both methods and let us know which one works better for you, which one was easier. i used helix method only because i saw some posts elsewhere using different CAD software with helix. helix method for me is easy, just not sure its the best method for certain projects, like perhaps doing lots of threading vs 1-2 parts like me, etc. i tried mmoe method, but didnt quite get it yet.

when i am doing CAD i keep thinking in perspective of the cutting tool, which may or may not be correct way to CAD, but my parts are simple.

one thing to note about helix, the sweeping curve ("cutting tool") has to be built on plane and positioned on a radius of round being cut, otherwise you'll get odd sweeps. making the "cut tool" as small as possible makes it easier to see the solids for subtraction, etc. i made a big triangle at 1st and had this huge solid taking up the screen, etc.

-

01-10-2014, 05:52 PM #5Registered

- Join Date

- Jul 2013

- Posts

- 32

If and when I do this, you'll be one of the first to know. I'm waiting for some team input prior to proceeding down this route. Not sure I'll take the time to try both methods unless the first one doesn't work for me. I'm still quite the newbie with the 3D cad and have primarily only been doing 2D cad for the last 1.5 years. This is a very part time thing for me at the moment. I'm only doing this particular project because I was willing to do it for free for the experience and for a potentially profitable partnership down the road - even though I won't hold my breath on that. Since I have a CNC router, the 3D experience will be helping me with with those type of projects in the future.

-

01-10-2014, 06:00 PM #6Registered

- Join Date

- Jan 2006

- Posts

- 93

i have only had ViaCAD for about a week. other than some mucking around with Rino3d years ago, this is my 1st crack at 2d/3d CAD. i have a idea that requires the use of CAD, but i have very limited knowldge about the machining world, thus i need to approach CAD carefully otherwise i'll keep CAD'ing parts that are very hard/impossible to CNC, etc. my prototype may run ~$200 in parts, but if my fluid dynamics knowledge doesnt fail me then i should end up with a successful item, and then maybe it goes to a small trial run of say 50 items.

-

01-11-2014, 06:10 AM #7

I definitely need to go back and re-read this thread, but for now... There is a plug-in for CamBam that I use for thread milling. I just define the center, pitch and diameter. I know it doesn't create a pretty picture, but it does get the thread cut.

Bob La Londe

http://www.YumaBassMan.com

-

01-16-2014, 03:48 PM #8Registered

- Join Date

- Jan 2006

- Posts

- 93

just a note. if you keep the closed curve (tool), if you move it the thread cut will adjust. likely a std feature of extrude curve along curve tool, i just didnt know that.

-

01-16-2014, 06:07 PM #9

I like this method. Simple, and fairly easy. The hardest part is drawing the single pitch helix, and that isn't that hard. The overall profile seems simple enough. Draw one full thread cycle, and then array copy as many as you need. I played with some of this stuff a while back to make a barley twist to replace a broken one on a chair. I since found it was easier and faster to make a cutter for the twist instead, and do it in 3 passes per side on a 4th axis, and write the code by hand.

Bob La Londe

http://www.YumaBassMan.com

Similar Threads

-

threading

By MetalZilla in forum News AnnouncementsReplies: 11Last Post: 01-26-2013, 01:32 AM -

Threading ???

By freemen in forum Uncategorised MetalWorking MachinesReplies: 3Last Post: 10-21-2010, 12:57 PM -

threading

By crustdog7 in forum MetalWork DiscussionReplies: 6Last Post: 10-18-2010, 08:03 PM -

help for npt threading

By teamus in forum G-Code ProgramingReplies: 0Last Post: 11-25-2008, 03:40 PM -

Threading

By brtlatjgt in forum MetalWork DiscussionReplies: 2Last Post: 05-11-2006, 04:08 PM

Reply With Quote

Reply With Quote