Supplier

United Grinding Group Management AG

Wankdorfalle 5

3014 Bern

Attended a fair

Trade FairAug 22, 2024 11:00| A blog article has been published

UNITED GRINDING at the BI-MU in Milan

The UNITED GRINDING Group will exhibit a wide range of machine tools at the BI-MU in Milan and present digital assistance systems.

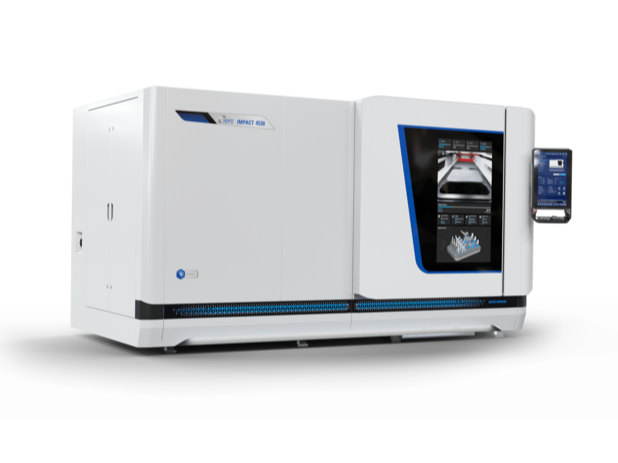

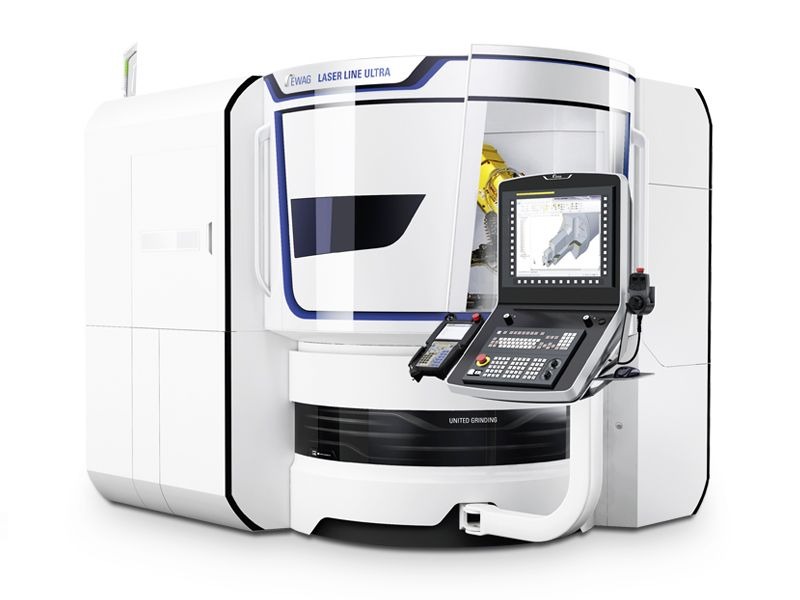

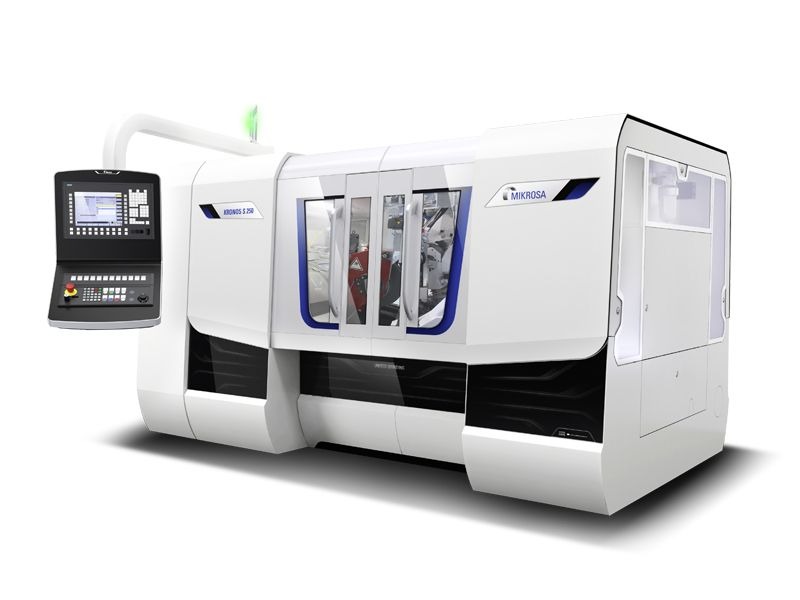

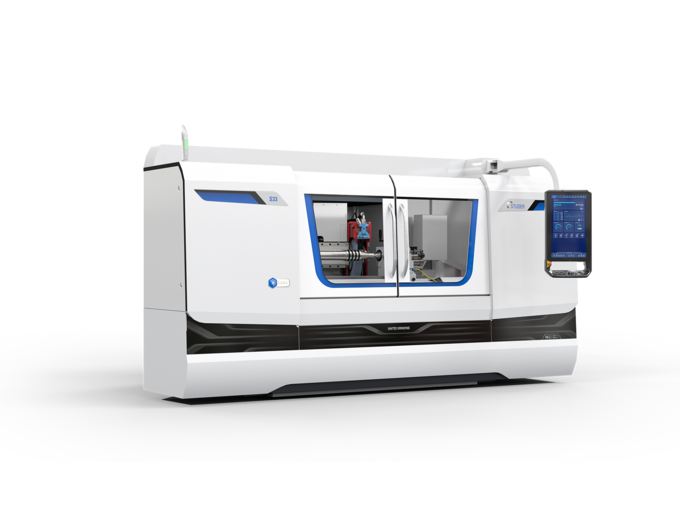

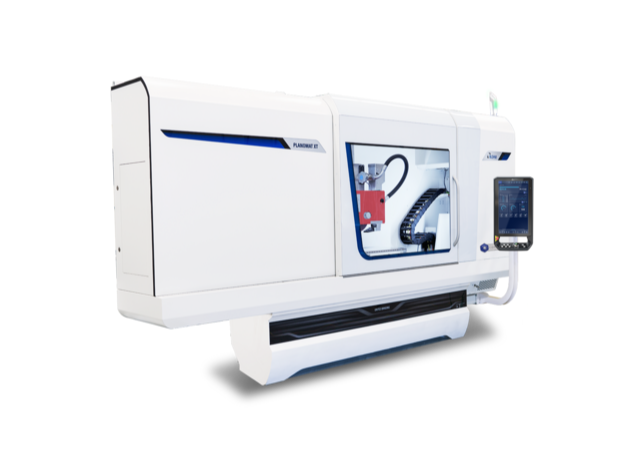

The UNITED GRINDING Group will exhibit this year four machines from its cylindrical grinding, surface and profile, and tool machining technology groups at BI-MU, as well as a selection of its UNITED GRINDING Digital Solutions™ products.

In the field of cylindrical grinding, STUDER will present its latest automation solution: the insertLoad &nbs...Mar 11, 2024 15:43| A press article has been released

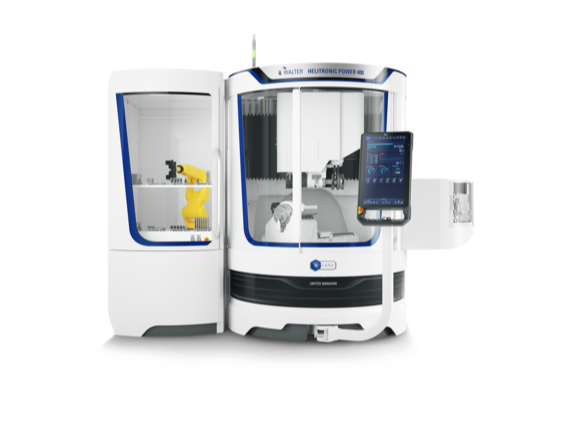

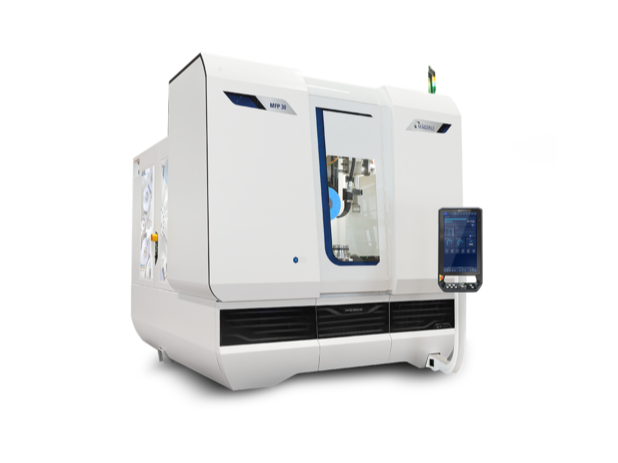

UNITED GRINDING presents innovation at the GrindingHub

The UNITED GRINDING Group will once again be represented with a prominent booth at GrindingHub under the motto "Stay Connected". This year, the group will be unveiling an innovation in the field of tool machining from its WALTER brand on the first day of the trade show, 14 May 2024 at 10 a.m. in hall 9, booth C51.

A fair has been created

Trade FairAttended a fair

Trade FairNov 26, 2021 17:08| 8 pictures have been added

Attended a fair

Trade Fair

- Show More Entries