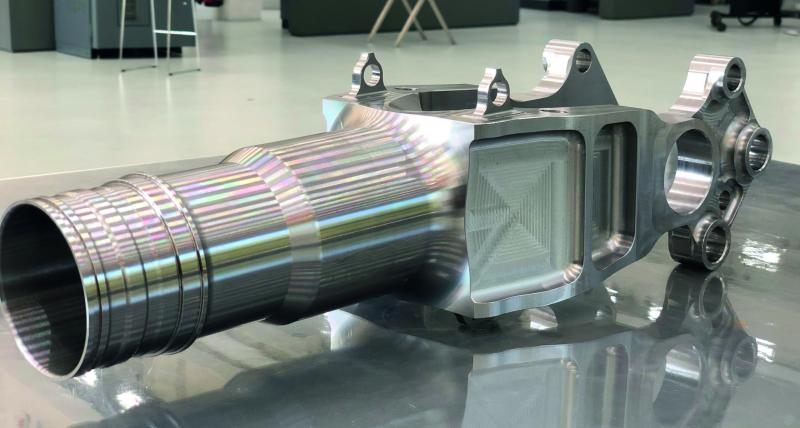

With its "Future machining solutions for aerospace components" project, Walter is focusing on an example component that is highly relevant to safety from the aerospace sector: The internal landing gear cylinders. These are subject to enormous forces, and their manufacture is correspondingly challenging. Added to this is the fact that the production includes nearly all types of metal machining and can have metal removal rates of up to 80% or up to 60% for close-contour blanks. It therefore requires a solution that is just as efficient as it is precise and reliable – both with regard to the tools and the machine. Modern multi-tasking machines completely machine the components, which have different dimensions depending on the type of aircraft, in just two clamping arrangements. The generic component chosen by Walter, a piston, was scaled to the WFL M35 and matched to all machining steps.

The ISO M material 40HM (1.7225) is used by many European aircraft manufacturers as an alternative to 300M, which has virtually identical properties. Different machining operations were used on the component: Roughing, finishing and groove turning, inside turning (up to 10×D), pocket milling, semi-finishing and finish-milling, ramping, spiral milling, boring and deep-hole drilling as well as chain drilling. In addition to the most suitable Walter tools, the Walter team also focused on innovative new machining strategies. It used top innovations, such as the vibration-damped Accure·tec boring bars to reduce vibrations, the Xill·tec™ milling cutters of the MC230 Advance range, which can be used universally, the D4120 indexable insert drills, the Xtra·tec® XT M5468 round insert milling cutters and M5008 high-feed milling cutters – the latter equipped with the newly developed Walter Tiger·tec® Gold cutting tool material WSP45G. The result: The machining goals of high cutting parameters, excellent surface finish qualities and maximum precision were achieved. All machining operations could be implemented with only two clamping arrangements – and correspondingly low non-productive times.

Germany

Germany