Whether lightweight components or parts weighing tons have to be moved...

..with hovercraft plates, it is possible with minimal effort. Areas of application are varied and range from use in assembly lines, QC applications, automation technology to positioning on tool machines.

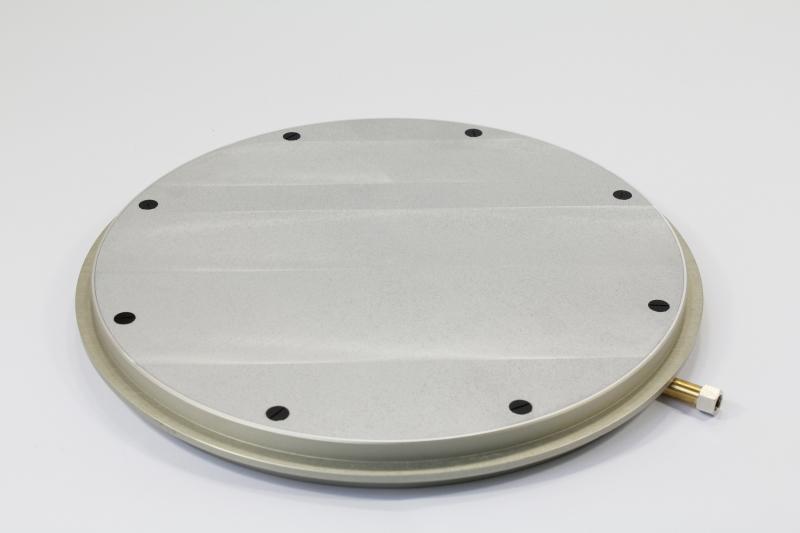

Accurately machined hovercraft chucks comprise of a base made in high-tensile aluminum alloy with an integrated, porous aluminium layer, which serves as an air distributor and creates an air cushion.

The top surface can be equipped for specific applications with bores, fittings or grooves for mounting or positioning of work pieces to be transported. The side connection for compressed air can be fitted with an easy to use valve handle.

The dimensions of these hovercraft elements depend on the expected weight load, application and working environment. For manual applications on machine tables, such as CNC machining centers, gaps in the form of T-slots have no effect on the bearing performance of the plates thanks to the excellent cushioning properties of the active micro-porous surface.

This type of hovercraft technology is also suitable when work pieces have to be transported using a contact-free method during manufacturing processes, whereby the plates are installed in a fixed base.

Even applications under clean room conditions can be carried out without hesitation, because some of the micro-porous aluminum materials have been tested for suitability in clean rooms and fulfill the requirements of clean room class 10.

Due to accurate micro-porosity the hover plates work with low air consumption and little noise.

Witte Barskamp KG

News

Hovercraft plates with micro-porous surface

Responsible for the content of this press release: Witte Barskamp GmbH & Co. KG

|

Micro porous hovercraft

|

Micro porous hovercraft plates

Contact

Witte Barskamp GmbH & Co. KG

Horndorfer Weg 26-28 21354 Bleckede- Barskamp

Germany

Germany Route planner

Route planner