YCM

Products

Realizing Your Smart Manufacturing Dream

Yeong Chin Machinery Industries Co., Ltd.

Horizontal machining centres

NH500A High Production 2-Pallet HMC

- High precision large-diameter roller type guideways on all axes, rapid feedrate up to 60 m/min.

- Max. work piece size can be ø880 x 1,000 mm ø34.6" x 39.4“ with up to 500 kg 1,102 lb weight.

- Dual-chip auger for excellent chip discharge

- Reliable automatic 2 pallets changer with 6 pallets option

NSV106A Ultra High Performance VMC

|

Vertical machining centre

Yeong Chin Machinery Industries Co., Ltd.

Vertical machining centres

- Large delta machining column and base for ensuring the highest stability during machining.

- 45 mm guideways on 3 axes have a super load capacity of up to 700 kg (1,543 lb)

- Wide ball screws and high precision roller type guideways on all axes

- Y-axis guideway span with optimal ratio

- Ultra-high controllability and stability

NXV1270A Compact and Affordable VMC

|

Vertical machining centre

Yeong Chin Machinery Industries Co., Ltd.

Vertical machining centres

- Robust roller linear guideways applied on 3 axes

- Rigid dual-wall castings on saddle and 6 blocks design on X-axis can easily support workpieces weighing up to 1,500 kg (3,307 lb)

- 4-linear guideways on Y-axis with superior large span ensures the best dynamic balance

- Wide base structure with 10 leveling pads

- The compact structure enables excellent floor space utilization

T11 High Speed Heavy Duty VMC

|

Vertical machining centre

Yeong Chin Machinery Industries Co., Ltd.

Vertical machining centres

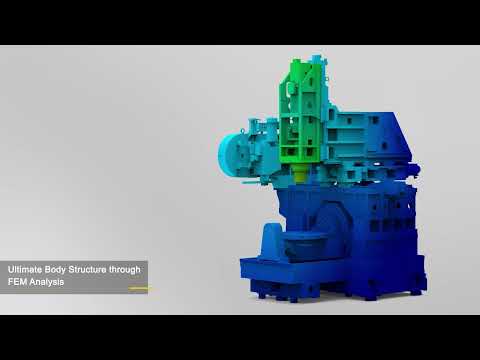

- The main structure casting parts were assessed by FEM analysis.

- The rigid Y-shaped and T-base structure has full stroke support without overhang that guarantees the most dynamic leveling accuracy.

- All axes are equipped with wider roller linear guides for running smoothness.

- The unique IDD spindle offers low spindle vibration and optimal heat isolation.

- The whole machine can be packed into the container for saving freight costs.

- ISO 14955 certified green machines

T13 High Speed Heavy Duty VMC

|

Vertical machining centre

Yeong Chin Machinery Industries Co., Ltd.

Vertical machining centres

- The main structure casting parts were assessed by FEM analysis.

- The rigid Y-shaped and T-base structure has full stroke support without overhang that guarantees the most dynamic leveling accuracy.

- All axes are equipped with wider roller linear guides for running smoothness.

- The unique IDD spindle offers low spindle vibration and optimal heat isolation.

- The whole machine can be packed into the container for saving freight costs.

- ISO 14955 certified green machines

UV650 Full 5-Axis VMC

|

Vertical machining centre

Yeong Chin Machinery Industries Co., Ltd.

Vertical machining centres

- The YCM in-house IDD spindle design provides power, speed, and stiffness required for the most adcerse machining applications while providing long spindle life.

- High precision rotory encoders in the B and C axes as a standard feature, allowing for the most demanding machining accuracies.

- ø650 mm ø25.6" 2-axis B/C type tilt-rotary can handle workpiece up to 300 kg 661 lb (0°~45°) / 200 kg 441 lb (45°~90°), enabling large working area for jig and fixture set-up.

BTX 250SY High Efficiency CNC Turn-Mill Center

|

Mill-Turn machining centre

Yeong Chin Machinery Industries Co., Ltd.

Mill-Turn machining centres

- Designed with a wide span between the two Z-axis boxways provide exceptional rigidity and stability during machining.

- The 12-station servo-driven turret for high reliability and time-saving tool change

- Packed with sub spindle, Y-axis, live tool turret and C-axis, these turn-mill features allow complex finished parts machining in just one setup, while also improving efficiency and accuracy.