Assfalg

Products

Assfalg GmbH

Barrel and vibratory finishing machines

Tub Vibrator - TV 15-SL | TV 40-SL | TV 100-SL | TV 200-SL | TV 350-SL | TV 500-SL | TV 500-SL Long | TV 1000-SL

67144, 67146, 67147, 67149

The tub slide grinding machines have a capacity from 23 to 1180 l.

They make it possible to process workpieces with different shapes and sizes. Sensitive workpieces can be contactless processed by means of chambers or workpiece carriers.

Features:

They make it possible to process workpieces with different shapes and sizes. Sensitive workpieces can be contactless processed by means of chambers or workpiece carriers.

Features:

- Sturdy, long-life construction with plastic-coated steel tub

- Consistent effect on the entire surface

- Very easy emptying of the tub after processing

- Ideal, also for longer workpieces

Centrifugal grinding machine - ASM 18 | ASM 60

|

Barrel and vibratory finishing machine

Assfalg GmbH

Barrel and vibratory finishing machines

67883, 67882

The ASM centrifugal machines are ideal for small parts.

With higher processing intensity, they deburr 10-20 times faster than vibratory fnishing machines. The centrifugal system can be planned as a stand-alone unit up to a fully automatic system.

Features:

With higher processing intensity, they deburr 10-20 times faster than vibratory fnishing machines. The centrifugal system can be planned as a stand-alone unit up to a fully automatic system.

Features:

- Sturdy, long-life construction with plastic-coated steel tub

- Easy emptying due to a tiltable work tank

- Compact device including base frame and manual separation (ASM 18)

Rotary Dryer - RT 200 | RT 400 | RT 600 | RT 800

|

Barrel and vibratory finishing machine

Assfalg GmbH

Barrel and vibratory finishing machines

67689, 68015, 67879, 67374

The rotary dryers are suitable for spot-free drying of all types of workpieces.

The use of the hot air blower ensures uniform drying of the workpieces and the drying granulate.

Features:

The use of the hot air blower ensures uniform drying of the workpieces and the drying granulate.

Features:

- Sturdy, long-life construction with plastic-coated steel tub

- Uniform effect over the entire surface

- Spotless drying - Consistent drying quality

- Increased service life of the drying granulate through use of the hot air blower

- Uniform rise of the work tank ensures good circulation and optimum workpiece transport

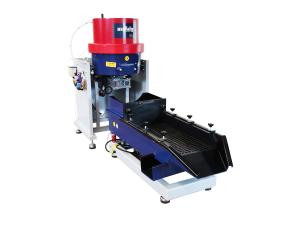

Rotary Vibrator - RV 15-SL | RV 40-SL |120-SL | 220-SL | 420-SL | RV 750-SL | RV 1000-SL

|

Barrel and vibratory finishing machine

Assfalg GmbH

Barrel and vibratory finishing machines

The rotary vibrators are universally applicable for deburring, edge rounding and from cleaning to polishing.

As single unit or combined with further after-treatment equipment such as drier or centrifuge, the rotary vibrator is upgraded to a fully automatic vibratory grinding centre.

Features:

As single unit or combined with further after-treatment equipment such as drier or centrifuge, the rotary vibrator is upgraded to a fully automatic vibratory grinding centre.

Features:

- Simple emptying via an outlet at the side of the machine

- With timer

- Sturdy, long-life construction with plastic-coated steel trough

- Integrated separation

- Easy to operate and maintain

TV 95-SL

|

Stone Vibration Deburring and Slide Grinding Machine

Assfalg GmbH

Barrel and vibratory finishing machines

The washing machine-sized tub vibratory finishing machine with a capacity of 95l is our standard machine and ideally suited for prototypes and small series.

Edges and surfaces of the most varied workpieces are machined unmanned. The larger the grinding wheel, the faster the deburring process.

Advantages:

Edges and surfaces of the most varied workpieces are machined unmanned. The larger the grinding wheel, the faster the deburring process.

Advantages:

- Deburring and polishing different parts with just one machine

- Simple separation with the use of a separator

- Vibration strength freely selectable

- Simple emptying via an outlet at the side of the machine

- Low-noise due to noise protection cover

- With timer

- Sturdy, long-life construction with plastic-coated steel tub inside