BAUBLIES GROUP

Products

Non-cutting surface treatment and thread production

Cutting tools

Roller burnishing tools

Ball burnishing tool

|

Multi-roller burnishing tools

Baublies AG

Roller burnishing tools

| up to 3500 rpm | |

| up to 500 rpm | |

| up to 0.02 mm | |

| 2–3 sec. | |

| emulsion or oil; filtration of the lubricant (<40 μm) can improve the surface quality and the tool life | |

| 5–20 revolutions | |

| surface roughness (Rz) up to 10 μm | |

| up to 45 HRC |

Tailor made tools for smoothening and work hardening of spherical surfaces. The tool contains conically arranged rollers. It is positioned to the workpiece under a defined setting-angle. Both workpiece and tool must rotate. During this process the spherical surface is burnished ?line by line?.

ADVANTAGES

- Useable on lathe machines with driven tools

- Very short machining time

- Slim design

- Fast return of investment

- Low machining forces

Einrollenwerkzeug, modulares System

|

Roller burnishing tool

Baublies AG

Roller burnishing tools

| cylindrical shafts also against shoulder (1 roll in use at a time) | |

| from 15mm | |

| up to 200 m/min | |

| up to 1 mm/U | |

| up to 1.2 mm | |

| up to 0.02 mm | |

| emulsion or oil; filtration of the lubricant (< 40 µm) can improve the surface quality and the tool life | |

| surface roughness up to 15 μm | |

| 45 HRC |

The modular single-roller tool system for lathe machines is an innovative solution for virtually all roller burnishing and roller compression tasks. A basic element is used to mount the interchangeable system components or rolling units. As a result, the tool can be converted in an extremely short time. This enables special machining tasks to be carried out quickly.

Expanding tool

|

Multi-roller burnishing tools

Baublies AG

Roller burnishing tools

| form closed connection of seat rings into valve housings | |

| as required | |

| as required | |

| up to 70 m/min | |

| up to 0.5 mm/rev | |

| emulsion or oil | |

| The seat ring is held by the tool so that automatic loading can take place before machining. |

Useable to connect valve seat rings into valve housings. The connection is form closed.

ADVANTAGES

- Automatic processing is possible

- The valve seat ring is fixed, guided and positioned by the tool

- Diameter range from DN 15 to DN 400 available

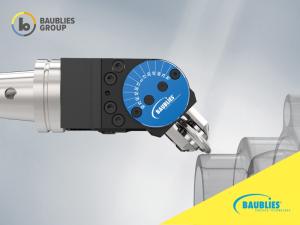

External roller burnishing tool PICCOLINO

|

Multi-roller burnishing tools

Baublies AG

Roller burnishing tools

| shaft against collar | |

| 1.0–7.9 mm | |

| −0.2 up to +0.1 mm | |

| 40 mm | |

| cylindrical shank Ø 6–22 mm Morse taper 1 to 3 | |

| up to 0.01 mm | |

| up to 0.04 mm | |

| clockwise (M3) | |

| always in rapid traverse (G0) | |

| emulsion or oil; filtration of the lubricant (<40 μm) canimprove the surface quality and the tool life | |

| surface roughness (Rz) up to 15 μm tolerance IT8 or better | |

| up to 45 HRC |

PICCOLINO external roller burnishing tools are a particularly compact design for use on machines with limited working space, such as multi-spindle and Swiss-type lathes or rotary transfer machines.

ADVANTAGES

- Very short machining time

- Surface finishes of the highest quality

- High productivity

- Workpiece is not subjected to lateral forces

- Both workpiece or tool can be driven

- Fast return of investment

- Slim design

- Usable on all common machines (no special machine required)

The best surface quality fast - that's a main characteristic of Baublies multi-roller burnishing tools. Depending on the roller burnishing task various numbers of hardened rollers are arranged in a cage. The machining times are kept short by using several rollers simultaneously. During roller burnishing with multi-roller tools, a roll-off process with kinematics similar to those of a planetary gear results. A taper supports the rollers and provides the contact force for forming the material. The rolling diameter is adjusted by axial shifting of the taper relative to the roller. Therefore multi-roller burnishing tools are particularly suitable for small and filigree workpieces.

Internal taper roller burnishing tool

|

Multi-roller burnishing tools

Baublies AG

Roller burnishing tools

| internal taper | |

| from 3 mm | |

| as required | |

| up to 0.01 mm | |

| up to 4 mm | |

| emulsion or oil; filtration of the lubricant (<40 μm) can improve the surface quality and the tool life | |

| up to 50 m/min. referred to the biggest rolling diameter | |

| 0.1–0.3 mm/rev | |

| 5–20 revolutions | |

| surface roughness (Rz) up to 15 μm | |

| up to 45 HRC |

Tool for smoothening and strain hardening of internal tapers. Internal springs generate the required rolling force. The value of the rolling force is defined by the preload of the tool. The spring characteristics can be adapted to the requirements of the workpiece.

ADVANTAGES

- Short machining time

- Both workpiece or tool can be driven

- High productivity

- Low investment costs

- Simple replacement of wear parts

- Compact dimensions

Product designation Single-roller burnishing tool for recess grooves

|

Single-roller burnishing tool

Baublies AG

Roller burnishing tools

| recess grooves | |

| up to 120 m/min | |

| 0.05–0.15 mm/rev | |

| up to 0.01 mm | |

| up to 5 mm (adjustable preload) | |

| emulsion or oil; filtration of the lubricant (< 40 μm) can improve the surface quality and the tool life | |

| surface roughness (Rz) up to 10 µm | |

| 45 HRC |

Single-roller burnishing tool for burnishing recess grooves.

ADVANTAGES

- Fast return of investment

- Optimized construction of rollers for machining application

- High productivity

- Slim design

- Simple replacement of wear parts

Roller burnishing tools for blind hole and through hole

|

Multi-roller burnishing tools

Baublies AG

Roller burnishing tools

Depending on the burnishing task various numbers of hardened rollers are arranged in a cage. The machining times are kept short by using several rollers simultaneously. During roller burnishing with multi-roller tools, a roll-off process with kinematics similar to those of a planetary gear results. A taper supports the rollers and provides the contact force for forming the material. The rolling diameter is adjusted by axial shifting of the taper relative to the roller. Therefore multi-roller burnishing tools are particularly suitable for small and filigree workpieces.

ADVANTAGES

- Workpiece is not subjected to lateral forces

- Reduced machining times

- Harder surface layers

- Increase in fatigue strength

- Greater contact area due to plateau formation

- Higher surface resistance to wear and corrosion

- Increase in material fatigue limits

- Reduced sliding friction coefficients, constant dimensions and high fitting accuracy

- Environmental sustainability (as no grinding dust is produced)

- Suitable for use on all standard machine tools

Roller burnishing tools for external machining

|

Multi-roller burnishing tools

Baublies AG

Roller burnishing tools

Depending on the burnishing task various numbers of hardened rollers are arranged in a cage. The machining times are kept short by using several rollers simultaneously. During roller burnishing with multi-roller tools, a roll-off process with kinematics similar to those of a planetary gear results. A taper supports the rollers and provides the contact force for forming the material. The rolling diameter is adjusted by axial shifting of the taper relative to the roller. Therefore multi-roller burnishing tools are particularly suitable for small and filigree workpieces.

ADVANTAGES

- Workpiece is not subjected to lateral forces

- Reduced machining times

- Harder surface layers

- Increase in fatigue strength

- Greater contact area due to plateau formation

- Higher surface resistance to wear and corrosion

- Increase in material fatigue limits

- Reduced sliding friction coefficients, constant dimensions and high fitting accuracy

- Environmental sustainability (as no grinding dust is produced)

- Suitable for use on all standard machine tools

Roller burnishing tools for through hole

|

Multi-roller burnishing tools

Baublies AG

Roller burnishing tools

Depending on the burnishing task various numbers of hardened rollers are arranged in a cage. The machining times are kept short by using several rollers simultaneously. During roller burnishing with multi-roller tools, a roll-off process with kinematics similar to those of a planetary gear results. A taper supports the rollers and provides the contact force for forming the material. The rolling diameter is adjusted by axial shifting of the taper relative to the roller. Therefore multi-roller burnishing tools are particularly suitable for small and filigree workpieces.

ADVANTAGES

- Workpiece is not subjected to lateral forces

- Reduced machining times

- Harder surface layers

- Increase in fatigue strength

- Greater contact area due to plateau formation

- Higher surface resistance to wear and corrosion

- Increase in material fatigue limits

- Reduced sliding friction coefficients, constant dimensions and high fitting accuracy

- Environmental sustainability (as no grinding dust is produced)

- Suitable for use on all standard machine tools

Single-roller burnishing tool for internal-, external- and taper machining

|

Single-roller burnishing tool

Baublies AG

Roller burnishing tools

| internal-, external-, and taper machining | |

| square shank 25 mm | |

| from 35 mm | |

| up to 200 m/min | |

| 0.05 – 0.3 mm/rev | |

| up to 0.02 mm | |

| up to 0.5 mm | |

| emulsion or oil; filtration of the lubricant (<40 μm) can improve the surface quality and the tool life | |

| surface roughness up to (Rz) 15 μm | |

| up to 45 HRC |

This single roller burnishing tool is used for burnishing rotationally symmetrical internal and external diameters. It also can be used for taper machining.

Advantages

- Universally usable

- Easy to use

- Slim design

- Fast return of investment

Variable single-roller burnishing tool

|

Single-roller burnishing tool

Baublies AG

Roller burnishing tools

| shafts, contours, recess grooves, plane surfaces | |

| square shank 20/25/32/40 mm | |

| ±90 ° in 15 °-steps adjustable | |

| 2 mm | |

| up to 200 m/min | |

| 0.05 – 0.3 mm/rev | |

| up to 0.02 mm | |

| up to 1 mm | |

| emulsion or oil; filtration of the lubricant (< 40 μm) can improve the surface quality and the tool life | |

| surface roughness (Rz) up to 15 μm | |

| up to 45 HRC |

Variable single-roller burnishing tool for smoothing and hardening internal and

external contours.

Variable single-roller burnishing tools are flexibly adjustable for various contours and can also be used in hard-to- reach places. The rolling unit can be swiveled by 180°.

ADVANTAGES

- Adjustable angle for various contours

- Optimal design of the rollers for profile machining

- Universally applicable due to compact design

Internal roller burnishing tool PICCOLINO

|

Multi-roller burnishing tool

BAUBLIES AG

Roller burnishing tools

| blind hole and through hole | |

| as required | |

| as required | |

| 4mm | |

| -0.1 to +0.1 mm | |

| from Ø 8 mm | |

| up to 0.02 mm | |

| up to 0.03 mm | |

| clockwise (M3) | |

| always in rapid traverse (G0) | |

| Emulsion or oil | |

| surface roughness (Rz) up to 12 µm tolerance IT8 or better | |

| up to 45 HRC |

PICCOLINO internal roller burnishing tools are a particularly compact design for use on machines with limited working space, such as multi-spindle and Swiss-Type lathes or rotary transfer machines.

ADVANTAGES:

- Very short machining time

- Surface finishes of the highest quality

- Easy to maintain

- High productivity

- Both workpiece or tool can rotate

- Fast return of investment

- Usable on all common machines (no special machine required)

The best surface quality fast - that's a main characteristic of Baublies multi-roller burnishing tools. Depending on the roller burnishing task various numbers of hardened rollers are arranged in a cage. The machining times are kept short by using several rollers simultaneously. During roller burnishing with multi-roller tools, a roll-off process with kinematics similar to those of a planetary gear results. A taper supports the rollers and provides the contact force for forming the material. The rolling diameter is adjusted by axial shifting of the taper relative to the roller. Therefore multi-roller burnishing tools are particularly suitable for small and filigree workpieces.