There is a lot to be said for the use of fully automated plant systems for tasks such as order picking girders in the steel trade. The parts being handled here are extremely bulky, the risk of potential accidents is high and the frequency of errors should not be underestimated. Networked plants and intralogistics can be an invaluable aid to handling operators and customers alike.

Automated operations in the steel trade require only a handful of employees to control and monitor a machining process which involves only minimal direct contact between personnel and material or machines – from the goods-in department through to loading the finished parts onto trucks for shipping. Different tasks from materials management through machining and order picking to shipment are all performed according to a programmed sequence and logical material flow process: A driveway along the hall wall permits part delivery and storage. Without encountering any crossroads, the girders and profiles are delivered straight to the warehouse, and travel from there to the sawing machines on infeed roller conveyors. High-performance sawing plants in the centre of the hall, such as mitre bandsaw HBP510-923G-NAP, cut the material. Some parts then pass through a conservation line for surface treatment, others are loaded immediately following sawing. Processing takes place on a program-controlled, bar-optimized basis. A transport management system ensures the material-saving assignment of starting lengths by matching them up to orders, and takes care of trouble-free material flow along the plant. The material and data arrive at the right time in the right place, enabling maximum output. Marking and labelling devices are used to identify material on an order-by-order basis. A separate transport system is provided for return transport of offcuts without disrupting or interrupting the processing sequence. Alongside the sawing machines, Behringer GmbH supplies all the peripherals from its own in-house steel works. CEO Christian Behringer has a positive take on the trend towards networked plants in the steel trade: “The benefits of automated intralogistics systems make absolute sense for a number of reasons. Alongside process reliability, employee safety, throughput speed and of course the prevention of errors all have a role to play.”

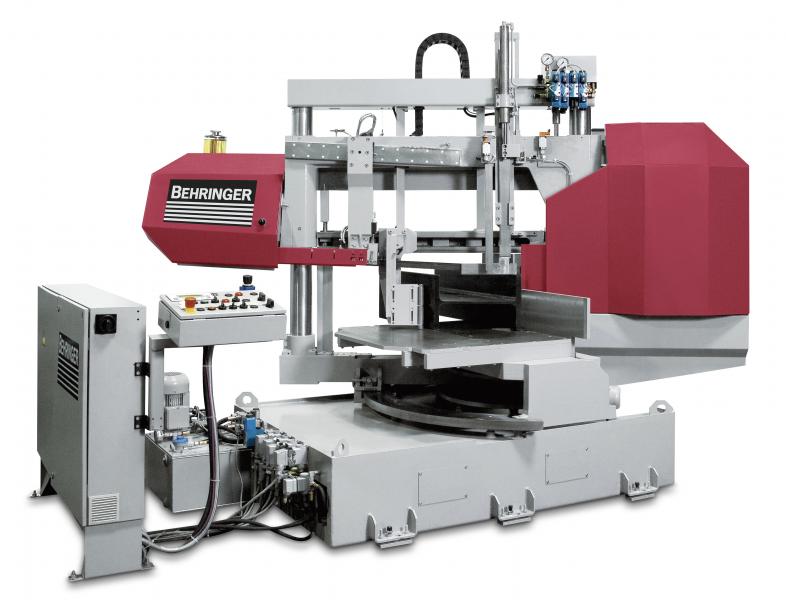

Features which guarantee optimum process reliability and a low frequency of errors are to be found not only in the machines themselves but also in the plant’s ideally coordinated control system. The robust, torsionally rigid design of the mitre bandsaw features saw blade guiding components made of vibration-damping grey cast iron, which extends the service life of tools and is the optimum choice for fully automated multiple shift operation.

From the warehouse, the raw parts are transferred using a hall crane onto the cross conveyor of the sawing line, where they are separated and fed towards the machine using an infeed roller conveyor with positioning device. Following on from the sawing process, the cut sections are sorted into cross conveyors in two directions. A cut section gripper selects the offcuts and short waste pieces. Short lengths are also sorted onto table surfaces and possibly also into containers. Depending on the material size and weight, different versions of the transport systems are used. In many cases, one particular variant might be the preferred option – for instance taking into account past user experience. Depending on the job in hand, good parts are deposited in the order picking zone for delivery, or are sent automatically for surface treatment to the blasting or painting booth. Markings and labels on the parts simplify the process of assigning parts for commissioning, or enable information to be scanned in.

All material movements are controlled from the central control desk. However, each sawing line has its own PC-based control system, from which the data is sent collectively to the higher-level control desk. The machines themselves have only a control system with functions for servicing, repair and maintenance. Here, mobile operator panels are used which can be docked onto different locations along the complete plant.

As safety takes top priority, all fully automated plants are surrounded by a protective fence, although connecting steps and raised control centre stations ensure an optimum overview of the entire process. The benefits for operators at the plant are evident: “By automating material flows and in particular due to the automated cut section disposal system, heavy and hazardous work processes are minimized”, says Christian Behringer. Investing in networked plants pays off, also in view of the demographic changes currently taking place. “We are already experiencing a shortage of skilled labour, and this is a situation we can defuse by introducing the wide-ranging automation of our plants”, he adds. Importantly too, future developments in the industry such as the interlinking of different machines mean that Behringer GmbH is on the right track with its networked systems.

Germany

Germany