4-RUNNER H1

Producing tube from coil - straightening, end-forming, bending and cutting – these are the specialities of the BLM GROUP 4-RUNNER family. "Family" is the keyword, since the 4-RUNNER H3 for processing tubes up to 22 mm (0.866”) in diameter is now joined by the 4-RUNNER H1, a system dedicated to complex processing of tube diameters up to 12.7 mm (0.5”).

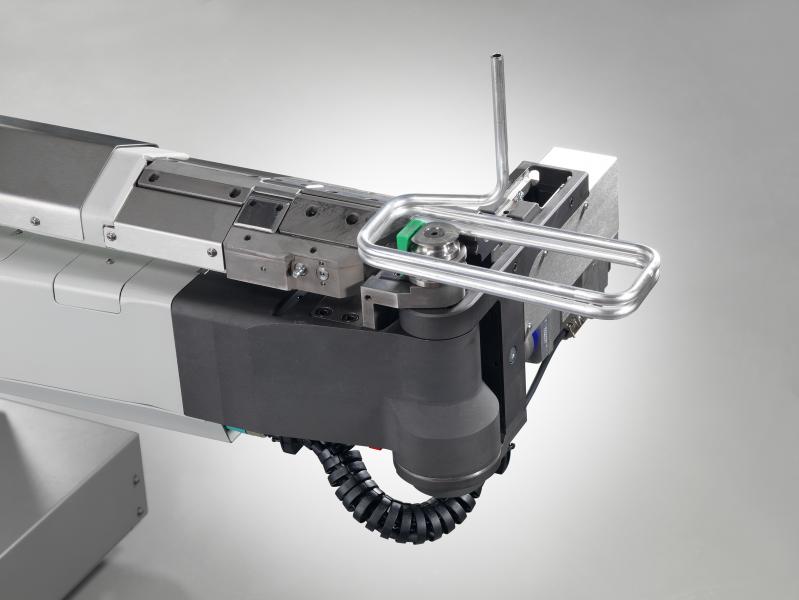

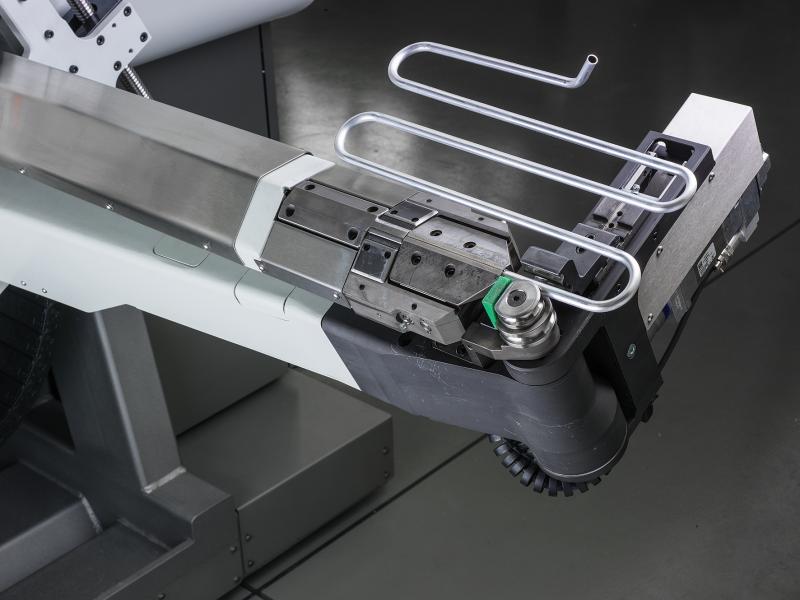

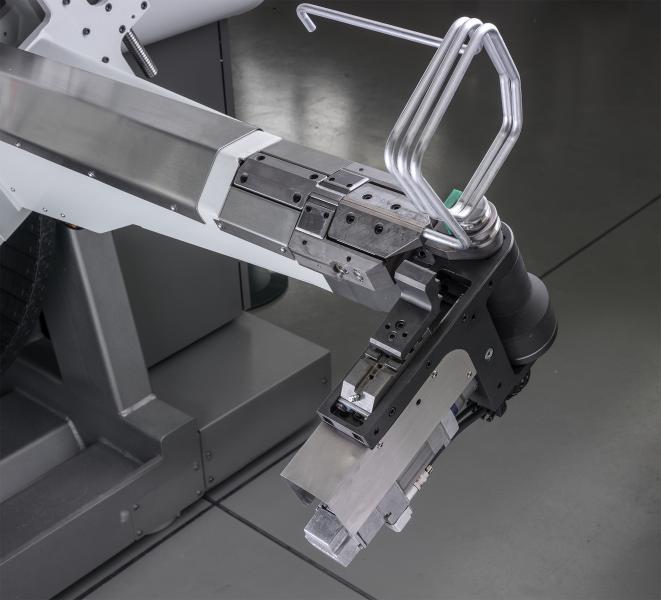

The 4-RUNNER H1 is the all-electric, fixed and variable radius coil-fed bending system. It is capable of flexion, right-hand and left-hand in-process and multi-radius bending.

The low-profile geometry bending head and in-process clamping zone offer significant process advantages. These unique features make it ideal for processing complex tubular parts, such as flat, 3D serpentines, and small tube, while combining the different bending technologies in the same part.

The 4-RUNNER H1 has up to fifteen controlled electric axes. All clamping and bending axes are electric, which means equipment calibration can be automated and made extremely simple. The torque control on the clamp ensures safe and repeatable gripping. Once identified, the correct calibration parameters can be saved and retrieved for future use on the same tools, reducing changeover and set-up requirements.

For feeding from coil, the 4-RUNNER H1 is equipped with a new motorized coil handler. The CNC-controlled handler allows tube advancement, recoil, and idle operation directly from the part program.

Orbital cutting, both internal (4RIPC) and external (4RC) on 4-RUNNER H1 is entirely electric. Two brushless motors control the rotation and the movement of the cutting wheel guaranteeing process accuracy and repeatability with no need for manual adjustments.

The 4-RUNNER H1 utilizes the powerful VGP3D 3D programming software package. BLM GROUP’s user-friendly software transforms ideas into production. As coordinates are entered, the part is gradually displayed on the monitor in three-dimensional graphics, allowing the user to verify programming accuracy on the fly. To validate part feasibility, VGP3D simulates the bending process. Program optimization is done on the screen, not by costly trial and error, allowing production to launch sooner.

BLM GROUP

BLM GROUP is the global partner for the entire tube machining process with a capillary worldwide presence and thousands of applications:

- BLM S.p.A., based in Cantù (CO), Italy, has specialised since 1960 in the production of CNC tube bending machines, tube forming machines, measuring units and devices for automated integration.

- ADIGE S.p.A., based in Levico Terme (TN), manufactures systems for laser-cutting tubes and machines for disc-cutting tubes, solids and sections. The range is completed by brushing machines, measuring systems, washing systems and collectors.

- ADIGE-SYS S.p.A., based in Levico Terme (TN), specialises in the production of "mixed" laser-cutting systems for cutting tubes and sheet metal, systems for laser-processing large-sized tubes and end cutting and removing lines for tubes and bars.

www.blmgroup.com

www.inspiredfortube.com

Facebook: http://www.facebook.com/BLMGROUP

Twitter: http://twitter.com/blmgroup

YouTube: http://www.youtube.com/BLMGROUPchannel

Google+: http://google.com/+Blmgroup

Italy

Italy