Continuous production with the high-performance end-cutting and processing system of BLM GROUP

During METAV 2018 from February 20-24 in Düsseldorf, BLM GROUP (Hall 15, Stand C17) displays a BC80, the high-performance, flexible system for cutting and processing ends. The high degree of automation allows the machine to produce different types of tube and solid bars continuously throughout the day, with productivity up to 2,200 pieces per hour.

Levico Terme - February 22th, 2018. BLM GROUP presents at METAV 2018 (Hall 15, Stand C17) BC80, the highly productive and completely automated machine that can produce pieces: cut to length, chamfered and measured, starting from either tube or solid bar with an automatic deburring system. BC80 is both the highest performing and cost-effective machine on the market designed for continuous 24/7 production of bushings up to 80 mm (3.15”) diameter and lengths from 10-350 mm (0.4” to 13.75”). This explains why both small suppliers and car manufacturers use this machine.

Perfect pieces made of tubes and bars

Processing scraps, waste and shavings are collected from the BC80 into separate containers. The pieces with lengths from 10 to 350 mm (0.4” to 13.78”) are unloaded through a two-position slide. The delimited working area prevents any chips from escaping while processing, minimizing the need for cleaning and maintenance. Furthermore, the dynamic washing process removes all residues from the parts produced, ensuring complete measurement reliability.

The bundle loader is available in different lengths up to 12.5 m (41.01’) and supports the high productivity of the machine, gently separating the tubes and bars during loading on the BC80. Production is continuous and it is not interrupted during the loading of the stock. A protection device ensures careful handling even on materials with delicate surfaces.

Extremely easy to use

The turning control panel, with a large touch screen, is very comfortable for the machine operator. The graphical interface, with an intuitive user guide, allows you to easily enter data and monitor the productivity of the machine. After entering the data of the order, such as the dimensions of the pieces to be produced and the properties of the material, the machine automatically determines the parameters to guarantee optimal cutting and production conditions.

BC80 automatically checks equipment wear. The continuous blade management technology extends tool life while optimizing cutting performance. The saw blades are quick and easy to change, the cutting head and the feed carriage retract leaving plenty of room for user operations.

Finally, the large doors on all sides of the machine make the maintenance and cleaning of the system easier.

Köster says: "During the development of the BC80, BLM GROUP has taken into account all the essential requirements that today's production systems must meet and was capable to bring together in a single system over 60 years of experience in cutting tubes and metal bars, with the processing technology of the ends."

With TS72, TWINCUT, CM602, BC80 and EM80, the BLM GROUP portfolio currently includes five different cutting-off machines offering a wide range of machining operations with their features and performances.

((Image captions))

((Photo of the working table of the machine))

BC80, on display by BLM GROUP at METAV 2018 is a high-performance end-cutting machine, which automatically produces a wide variety of different parts from deburred and measured tubes and bars.

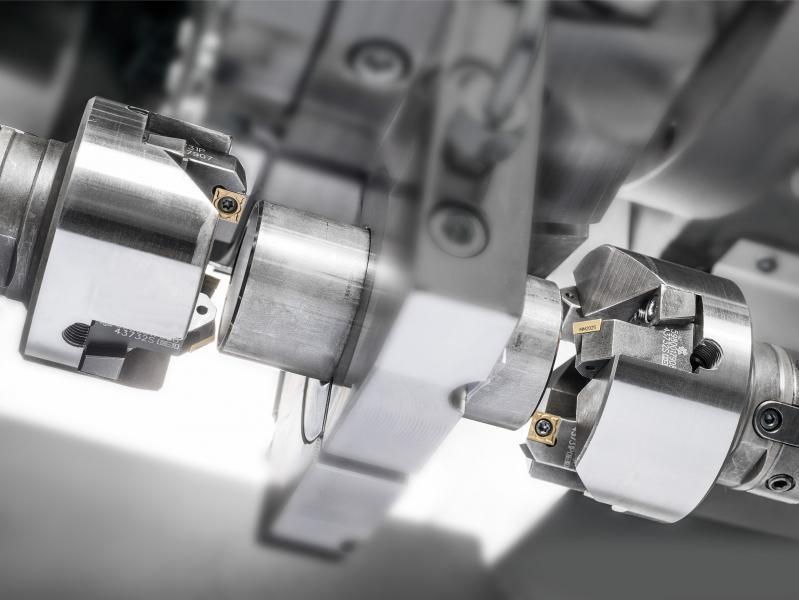

((Equipment photo))

With the various tooling options, BC80 covers a wide range of different processing modes for tube and bar ends.

BLM GROUP

BLM GROUP is a global partner for the entire tube fabrication industry with a worldwide presence and thousands of successful installations in a wide variety of industries.

- BLM SPA, based in Cantù (CO), specializes in the production of CNC tube-bending machines, end forming, wire bending equipment and related automation devices.

- ADIGE SPA based in Levico Terme (TN), manufactures systems for laser-cutting tubes and machines for saw cutting tubes, bars and sections. The range is augmented with wire brushing machines, measuring systems, washing systems and collectors.

- ADIGE-SYS SPA based in Levico Terme (TN) specializes in the production of "hybrid" laser-cutting systems for cutting both tubes and sheet metal, plus a line of large capacity laser tube cutting machines and related part handling.

www.blmgroup.com

www.inspiredfortube.com

Facebook: www.facebook.com/BLMGROUP

YouTube: www.youtube.com/BLMGROUPchannel

Linkedin: www.linkedin.com/company/blmgroup

Twitter: http://twitter.com/blmgroup

Italy

Italy