Intec 2017: BLM GROUP makes the difference

BLM GROUP will be at Intec from March 7 to 10, 2017, with E-TURN32: the in-process, multi-radius, all-electric, right-hand and left-hand bending system for tubes and profiles. The E-TURN will be showcasing the type of technology that is incorporated into the complete line up of BLM Group saws, lasers, benders and end formers for processing tube, wire and sheet metal components.

Cantù, 7 March 2017.

The E-TURN32 bending system is the perfect example of the BLM GROUP philosophy applied to its products. It is the industry leader in terms of performance, accuracy, reliably and flexibility, the system is appreciated for its ability to take on particularly complex bending jobs. It often succeeds where other benders fail. BLM GROUP has what it takes: to bend tubes or wire, laser cut tubes and sheets, end-form tubes or saw solid bar or tubes. BLM GROUP makes the difference

LT8.10 makes the difference

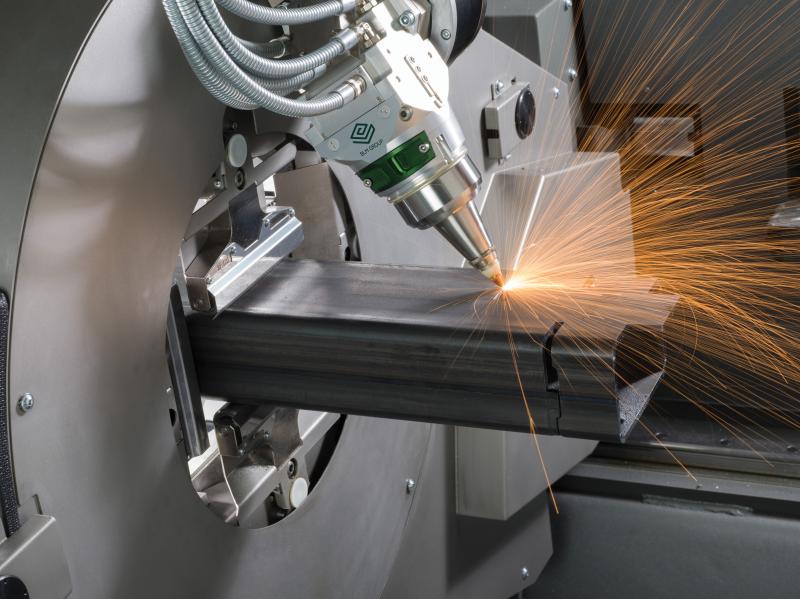

Today, 3D laser (tilt) cutting is a reality regardless of the resonator technology (CO2 or Fiber), for straight or bent tubes up to as large as 610 millimetres (24”). The LT8.10 automated laser tube cutter satisfies the accuracy and quality needs for cutting straight tubes and doing non-orthogonal cutting such as weld preparations.

LT5 makes the difference

The LT5 laser system combines the main features of the Lasertube family with simple, no-nonsense design choices to maintain an extremely advantageous quality/price ratio.

It is the optimal machine to enter the laser cutting world for tubes of up to 120 millimetres (4.75”) in diameter. It is also available in ‘round-tube-only’ configuration for fast, clean and cost effective straight tube cut off that beats traditional sawing or shear type cutting systems.

LT-FREE makes the difference

The LT-FREE five-axis laser cutting system developed by BLM GROUP ensures top-notch flexibility and simplicity of use for cutting 3D parts in different shapes. Bent tubes, flat and drawn sheet metal, hydroformed components and welded assemblies can pierced and trimmed simply and accurately. From the raw tubes to the finished part in one step.

All-In-One makes the difference

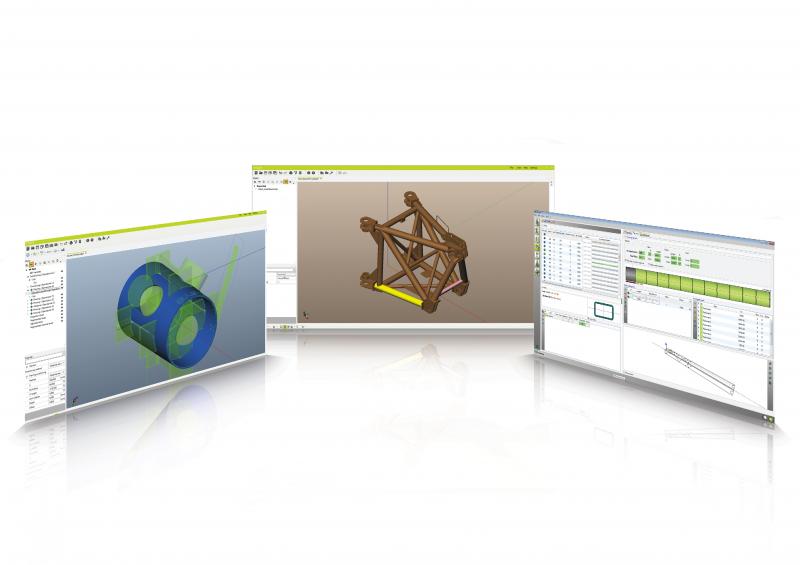

Tube processing system integration is a specialty of BLM GROUP. The Group's extensive experience and deep knowledge of bending systems, laser cutting and forming is exploited to integrate multiple machines with the goal of cutting the time needed to make a finished part. The software is the key component that makes it all work. Software for automatically creating laser cutting and bending system programs by importing a 3D model of the finished part or for managing the interface between systems to make the part right from the start.

Artube makes the difference

Artube is the Lasertube parametric 3D CAD-CAM programming system. It is cleverly designed to fully exploit all the potential of each system. Three-dimensional file import, special profile management and fully automated programming (to create part programs from an imported file without the need for additional programmer interaction) are just some of the most recent developments of the software developed for use on all Lasertube systems.

One particular innovation is the ability to import a file of a bent tube and then use the ‘cut-and-bend’ technique on the laser to make a bent part with the laser system instead of a bender.

E-FLEX makes the difference

E-FLEX is the single head wire bending system that joins the DH double-head systems and completes the line-up of wire bending machines.

With the outstanding flexibility provided by the double turret bending head, E-FLEX can make complex 3D parts which are not excessively developed in height.

One of the strengths worth mentioning is the VGP3D programming and simulation software used on all bending systems of the Group. It has no equals in the industry.

For more information:

Giovanni Zacco – BLM GROUP Communications

e-mail: [email protected]

Tel.: +39 031 7070200

BLM GROUP

BLM GROUP is a global partner for the entire tube fabrication industry with a worldwide presence and thousands of successful installations in a broad variety of industries.

- BLM S.p.A., based in Cantù (CO), specialises in the production of CNC tube-bending machines, end-forming, wire bending equipment and related automation devices.

- ADIGE S.p.A., based in Levico Terme (TN), manufactures systems for laser-cutting tubes and sawing machines for cutting tubes, bars and sections. The range is augmented with wire brushing machines, measuring systems, washing systems and collectors.

- ADIGE-SYS S.p.A., based in Levico Terme (TN), specialises in the production of "hybrid" laser-cutting systems for tubes and sheet metal, plus a line of large capacity laser tube cutting machines and related part handling systems.

Facebook: http://www.facebook.com/BLMGROUP

Twitter: http://twitter.com/blmgroup

YouTube: http://www.youtube.com/BLMGROUPchannel

Linkedin: http://www.linkedin.com/company/blmgroup

Italy

Italy