LT-FREE: finished pieces, in a single step

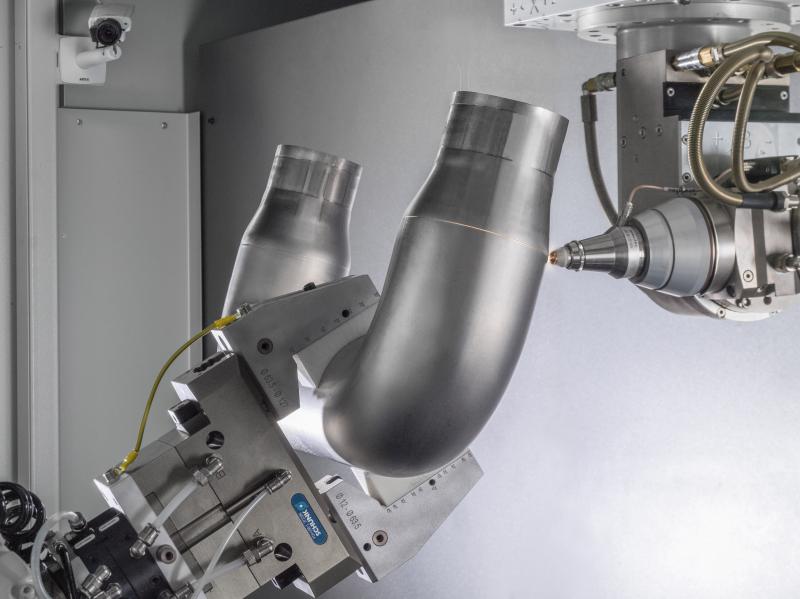

LT-FREE is the 5-axis laser cutting system that the BLM GROUP developed to offer maximum operating flexibility and ease of use in the laser cutting of bent tubes, flat and moulded sheet metal, hydroformed components and welded assemblies. A few technical innovations make the system even more powerful and efficient.

The true innovation of this versatile system is the new 3D graphic programming software Artcut. Artcut allows off-line programming and simulation of the LT‑FREE work cycle thus reducing times and costs of production and allowing the system to work 24/7.

Programming with the new Artcut software is simple, fast and suitable for any 3D piece.

Artcut allows you to work on your 3D cutting system model, complete with all of the components you acquired. Each component is visible in a realistic fashion; it is possible to drag objects with drag&drop and a series of available additional graphic supports make programming a simple and intuitive experience.

With off-line programming you also have all the time you need to program, simulate, make quotes, quantify the times and costs without having to stop the machine.

This means that you have the time for an accurate programming and the assurance of continued production 24/7.

Artcut also helps with the correction of the trajectories of the axis in order to avoid collisions of the head with the piece or other elements of the machine. Thanks to the collision resolution algorithm, Artcut autonomously resolves collisions.

Artcut makes the use of this 5-axis laser cutting system very fast and easy, eliminating its operating limits and allowing it to be used in very different application, from prototyping up to production in series, in sectors such as the automotive, aerospace, motorcycles, appliances, HVAC, furniture or in light carpentries working with tubes and assemblies.

Using a fibre laser source of 1 and 3 kW grants LT-FREE the ability to cut a very wide range of materials with low power consumptions and low maintenance costs.

In order to meet any specific requirement, four different system configurations are available:

- ENTRY LEVEL is the configuration dedicated to prototyping and job shops that work in small production volumes. The system is equipped with a single table to which the workpieces should be attached. When the quality of the work and the simplicity of use are more important than the production times, this is clearly the most interesting configuration.

- PIECE VALUE is the system intended for mass production, typically in the automotive sector. Applications that don’t have frequent need for retooling, but require high productivity can find in this rotating table configuration the ideal solution.

- MID-FLEX is the configuration adapted for those that have small size pieces with some extra requirements in terms of productivity, the two translating tables that operate in separate workstations allow optimizing the cycle times executing the loading/unloading operations in background.

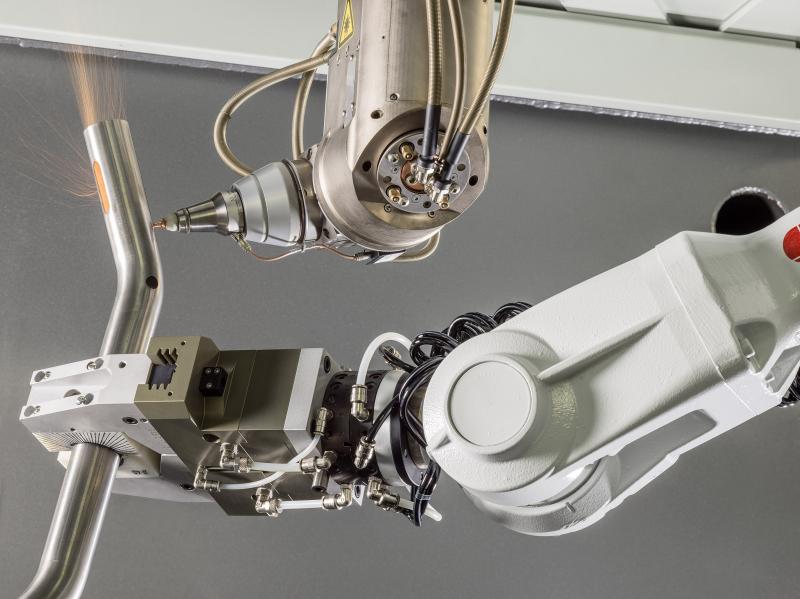

- HIGH FLEX is the most comprehensive, versatile and powerful configuration, with two independent and robotic tables that ensure the maximum level of flexibility. In addition to sheet metal and mechanical assemblies, this system is capable of working with precision and efficiency in curved or hydroformed tubes that, during processing, can be held in position by the robot without requiring complex equipment.

In the HIGH FLEX and PIECE VALUE versions it is also available the Bin Picking system, a powerful loading/unloading station that allows the LT-FREE system to work in complete autonomy.

With the help of a precise vision system, it is capable of identifying the single pieces inside a container where the pieces to be processed are stored, collect one, via an external anthropomorphic robot, and deposit it on the work table of the LT-FREE system, ready for processing. The cycle is concluded with the collection from that same work table of the previously processed piece, which is placed in another container for the storage of finished pieces.

More generally, the presence of an external loading robot offers multiple opportunities to customize the loading-unloading system of the LT-FREE system with automatic solutions that include the possible interconnection with other BLM GROUP systems. It is possible, for example, to assume that the robot, placed on a liner conveyor, can collect the piece directly unloading it on a tube bender or collecting it from an interconnecting conveyor belt to take it to the LT-FREE system.

All in a continuous cycle operating process 24/7, capable of ensuring fixed work times and, therefore, constant productivity at known costs.

For more information:

Giovanni Zacco – Communication BLM GROUP

E-Mail: [email protected]

Tel.: +39 031 7070200

BLM GROUP

BLM GROUP is a global partner for the entire tube fabrication industry with a worldwide presence and thousands of successful installations in a wide variety of industries.

- BLM SPA, based in Cantù (CO), specializes in the production of CNC tube-bending machines, end forming, wire bending equipment and related automation devices.

- ADIGE SPA based in Levico Terme (TN), manufactures systems for laser-cutting tubes and machines for saw cutting tubes, bars and sections. The range is augmented with wire brushing machines, measuring systems, washing systems and collectors.

- ADIGE-SYS SPA based in Levico Terme (TN) specializes in the production of "hybrid" laser-cutting systems for cutting both tubes and sheet metal, plus a line of large capacity laser tube cutting machines and related part handling.

Facebook: www.facebook.com/BLMGROUP

YouTube: www.youtube.com/BLMGROUPchannel

Linkedin: www.linkedin.com/company/blmgroup

Twitter: http://twitter.com/blmgroup

Italy

Italy