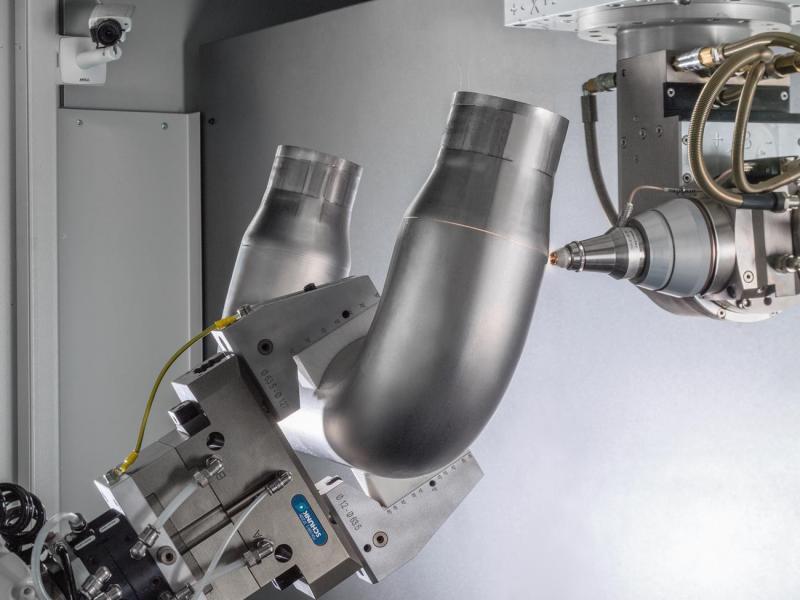

The LT-FREE five-axis laser cutting system developed by BLM GROUP ensures top-notch flexibility and simplicity of use for cutting 3D parts in different shapes. Curved tubes, flat and drawn sheets, hydroformed components and welded assemblies can pierced and trimmed simply and accurately.

Cantù, in January 2016. All the complex operations normally needed to obtain high-quality parts can now be carried out very easily in a single cycle making feasible jobs which were not even imaginable with traditional techniques. Starting with simple, effective off-line programming, the LT-FREE makes completely finished parts, cutting the number of semi-finished products and consequently reducing material handling costs and storage space to make the process cost-effective and lean.

The LT-FREE is created for a wide range of different applications, from prototyping to final production, in the automotive, aerospace, motorcycle, household appliance, HVAC, furniture and light constructions sectors to name a few and wherever tubes and assemblies are processed.

Four different system configurations are available to satisfy all application needs:

- Entry Level is the configuration dedicated to prototyping and ideal for job shops where small volumes are made. The system is equipped with a single table onto which the parts to be processed are fixed. This configuration is interesting when job quality and simplicity are more important than production time.

- Mid-Flex is the configuration created for shops where small parts are processed and to answer the need for faster production. Two shifting tables work in split stations allowing to optimise cycle times and carry out loading and unloading operations in the background.

- Piece Value is the system for standard production, particularly for the automotive sector. Equipped with a rotary table, it is ideal for applications requiring high productivity and infrequent retooling.

- High Flex is the most complete configuration. It is versatile and high-performing with two independent, robotised tables for maximum flexibility. In addition to sheets and mechanical assemblies, the system can process bent and hydroformed tubes accurately and efficiently. The parts are held in position by the robots during processing with no need for complex equipment.

The use of 1 and 2 kW fibre laser sources (higher power sources up to 5 kW are available according to applications) allowing LT-FREE to cut a very wide range of materials in energy-efficient manner with low maintenance costs.

Over a decade of BLM GROUP's laser cutting experience is made available to users in a cutting parameter database guaranteeing high reliability with all feasible materials and thicknesses.

The LT-FREE is easy to use. With the programming and simulation software, users can easily import 3D assemblies, rapidly identify the components to be processed, automatically generate part programs, graphically simulate the cycle to identify any collisions and modify the program off-line before transferring it to the machine. All this with no unnecessary waste of time. The software package also includes an efficient clamp design module for making tools rapidly with the LT-FREE system itself.

Italy

Italy