Perfect for microtools – world premiere of the LC54-DIGILOG at EMO 2025

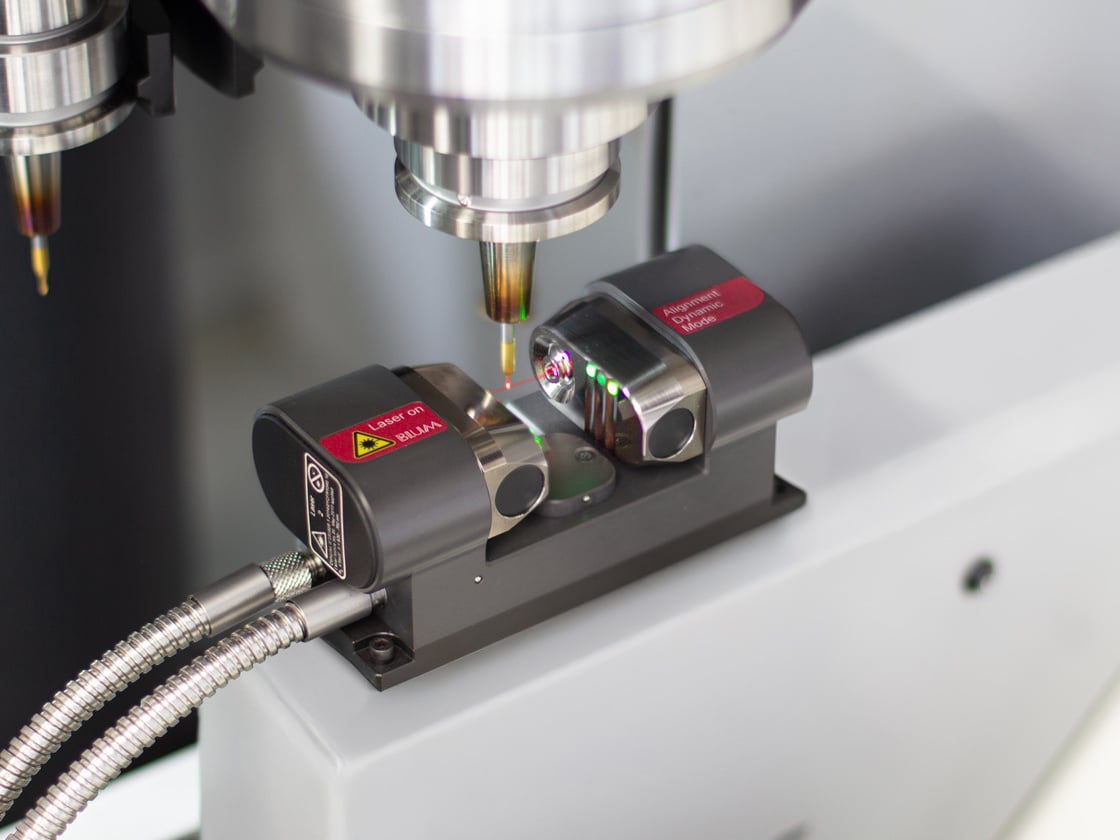

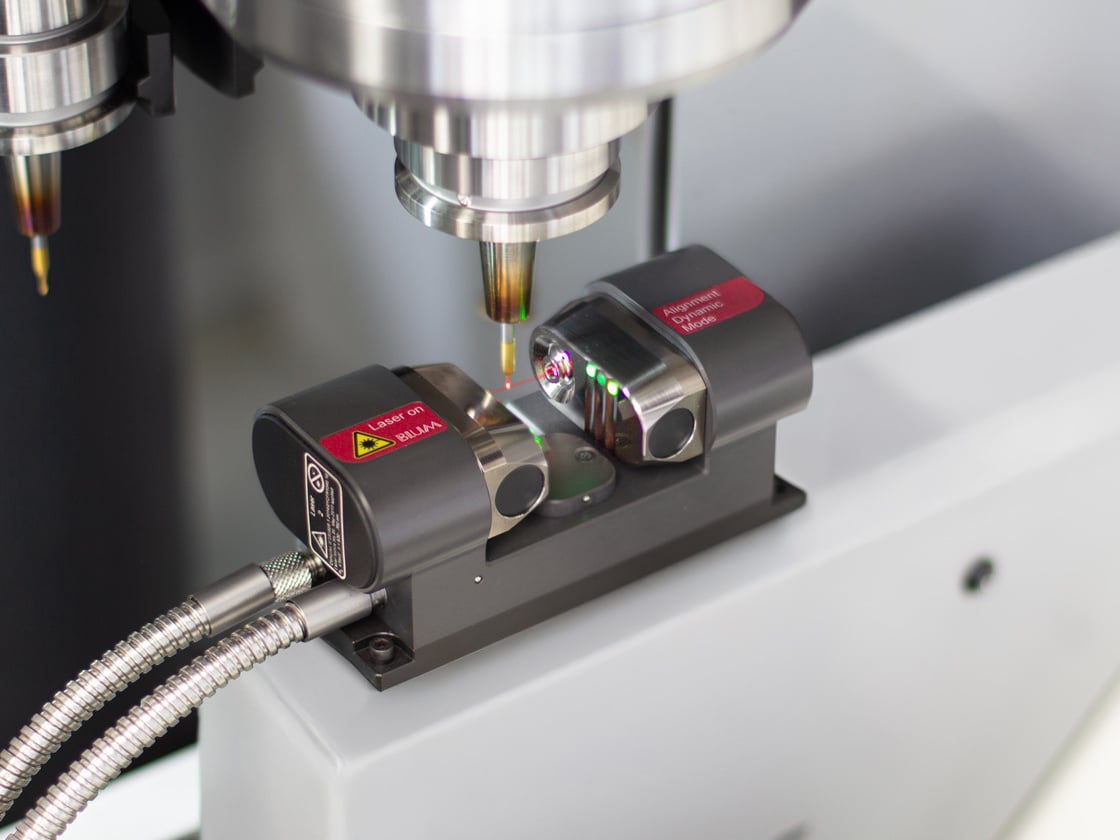

Blum-Novotest, leading provider of innovative and high-quality measuring and testing technology, will be presenting the new LC54-DIGILOG, the most compact laser measuring system in the LaserControl DIGILOG series to date, at EMO 2025 in Hanover (Hall 5, Booth D31). Specially developed for tool measurement and monitoring in micro-machining, the system sets new standards in precision, compactness and process reliability.

Winfried Weiland, Head of Marketing at Blum-Novotest, explains: "The demands on precision in micro-machining are constantly growing – especially when it comes to measuring extremely small tools. With the new LC54-DIGILOG, we have developed a system that not only meets these challenges but also sets new standards. It offers the entire range of functions of the tried-and-tested DIGILOG laser measuring systems for tools in the 10 μm to 16 mm diameter range. It has been designed from the ground up for use in highly compact machine concepts and impresses with a wide range of technical innovations that make it the most powerful and precise laser measurement system in its class”.

The direct successor to the LaserControl Nano NT, which has proven its worth over many years, the LC54-DIGILOG builds on its strengths and surpasses it in nearly all areas. The key component of the new system is DIGILOG technology, which was first introduced in 2017. While classic digital/switching laser measuring systems generate only a few signals by shading the tool, the LC54-DIGILOG generates several thousand measured values per second, with dynamic adjustment of the measurement speed to the nominal speed of the tool. Each cutting edge is measured individually, enabling precise comparison between the shortest and longest cutting edges. This results in a repeat accuracy of 0.2 μm (2σ) and concentricity errors caused by contamination on the tool holder, for example, are automatically detected. The system also identifies any dirt or cooling lubricant that adheres to the tool and excludes this from the measurement result.

The numerous innovations that BLUM developers have integrated into the LC54-DIGILOG give users tangible benefits: Measurement and testing times have been reduced by up to 60 percent. At the same time, the system laser optics have been perfected for the requirements of microtools. An optimised beam shape and a 30 percent reduction in the focus diameter allow for absolute accuracy that surpasses all previous systems – even those that use blue laser light. The MicroTool mode is a special innovation: For microtools, this is activated automatically and enables another significant increase in measuring accuracy, which is a decisive advance for precise measurement of even the most delicate tools.

A central element of the LaserControl DIGILOG series is its seamless integration into the powerful LC-VISION measuring and visualisation software. This was specially developed for DIGILOG systems from BLUM and offers an intuitive user interface for configuring, visualising and evaluating measurement processes. The new GrindingControl function for LC-VISION will make its debut at EMO: It allow for precise determination of the actual geometry of grinding tools. Using intelligent algorithms, the software determines an optimised machining dimension from the recorded measurement data and automatically transfers it to the tool table. Alternatively, standard measuring sequences can be generated very conveniently thanks to integration into common CAD/CAM systems such as Mastercam and introduced into the machining programme.

“Another highlight of our EMO trade fair appearance will be the collaboration with clamping technology manufacturer SCHUNK”, explains Winfried Weiland. "Their battery-powered clamping devices will be compatible with our BRC radio technology in the future, allowing for wireless, automated communication between the clamping technology and the machine. What is especially beneficial for customers: If BLUM measuring systems with BRC radio technology are already installed in the machine, the new SCHUNK clamping devices can be integrated and operated particularly easily and cost-effectively. This saves time, reduces installation work and increases flexibility in production processes.

Blum-Novotest, leading provider of innovative and high-quality measuring and testing technology, will be presenting the new LC54-DIGILOG, the most compact laser measuring system in the LaserControl DIGILOG series to date, at EMO 2025 in Hanover (Hall 5, Booth D31). Specially developed for tool measurement and monitoring in micro-machining, the system sets new standards in precision, compactness and process reliability.

Winfried Weiland, Head of Marketing at Blum-Novotest, explains: "The demands on precision in micro-machining are constantly growing – especially when it comes to measuring extremely small tools. With the new LC54-DIGILOG, we have developed a system that not only meets these challenges but also sets new standards. It offers the entire range of functions of the tried-and-tested DIGILOG laser measuring systems for tools in the 10 μm to 16 mm diameter range. It has been designed from the ground up for use in highly compact machine concepts and impresses with a wide range of technical innovations that make it the most powerful and precise laser measurement system in its class”.

The direct successor to the LaserControl Nano NT, which has proven its worth over many years, the LC54-DIGILOG builds on its strengths and surpasses it in nearly all areas. The key component of the new system is DIGILOG technology, which was first introduced in 2017. While classic digital/switching laser measuring systems generate only a few signals by shading the tool, the LC54-DIGILOG generates several thousand measured values per second, with dynamic adjustment of the measurement speed to the nominal speed of the tool. Each cutting edge is measured individually, enabling precise comparison between the shortest and longest cutting edges. This results in a repeat accuracy of 0.2 μm (2σ) and concentricity errors caused by contamination on the tool holder, for example, are automatically detected. The system also identifies any dirt or cooling lubricant that adheres to the tool and excludes this from the measurement result.

The numerous innovations that BLUM developers have integrated into the LC54-DIGILOG give users tangible benefits: Measurement and testing times have been reduced by up to 60 percent. At the same time, the system laser optics have been perfected for the requirements of microtools. An optimised beam shape and a 30 percent reduction in the focus diameter allow for absolute accuracy that surpasses all previous systems – even those that use blue laser light. The MicroTool mode is a special innovation: For microtools, this is activated automatically and enables another significant increase in measuring accuracy, which is a decisive advance for precise measurement of even the most delicate tools.

A central element of the LaserControl DIGILOG series is its seamless integration into the powerful LC-VISION measuring and visualisation software. This was specially developed for DIGILOG systems from BLUM and offers an intuitive user interface for configuring, visualising and evaluating measurement processes. The new GrindingControl function for LC-VISION will make its debut at EMO: It allow for precise determination of the actual geometry of grinding tools. Using intelligent algorithms, the software determines an optimised machining dimension from the recorded measurement data and automatically transfers it to the tool table. Alternatively, standard measuring sequences can be generated very conveniently thanks to integration into common CAD/CAM systems such as Mastercam and introduced into the machining programme.

“Another highlight of our EMO trade fair appearance will be the collaboration with clamping technology manufacturer SCHUNK”, explains Winfried Weiland. "Their battery-powered clamping devices will be compatible with our BRC radio technology in the future, allowing for wireless, automated communication between the clamping technology and the machine. What is especially beneficial for customers: If BLUM measuring systems with BRC radio technology are already installed in the machine, the new SCHUNK clamping devices can be integrated and operated particularly easily and cost-effectively. This saves time, reduces installation work and increases flexibility in production processes.