Top quality under the harshest conditions

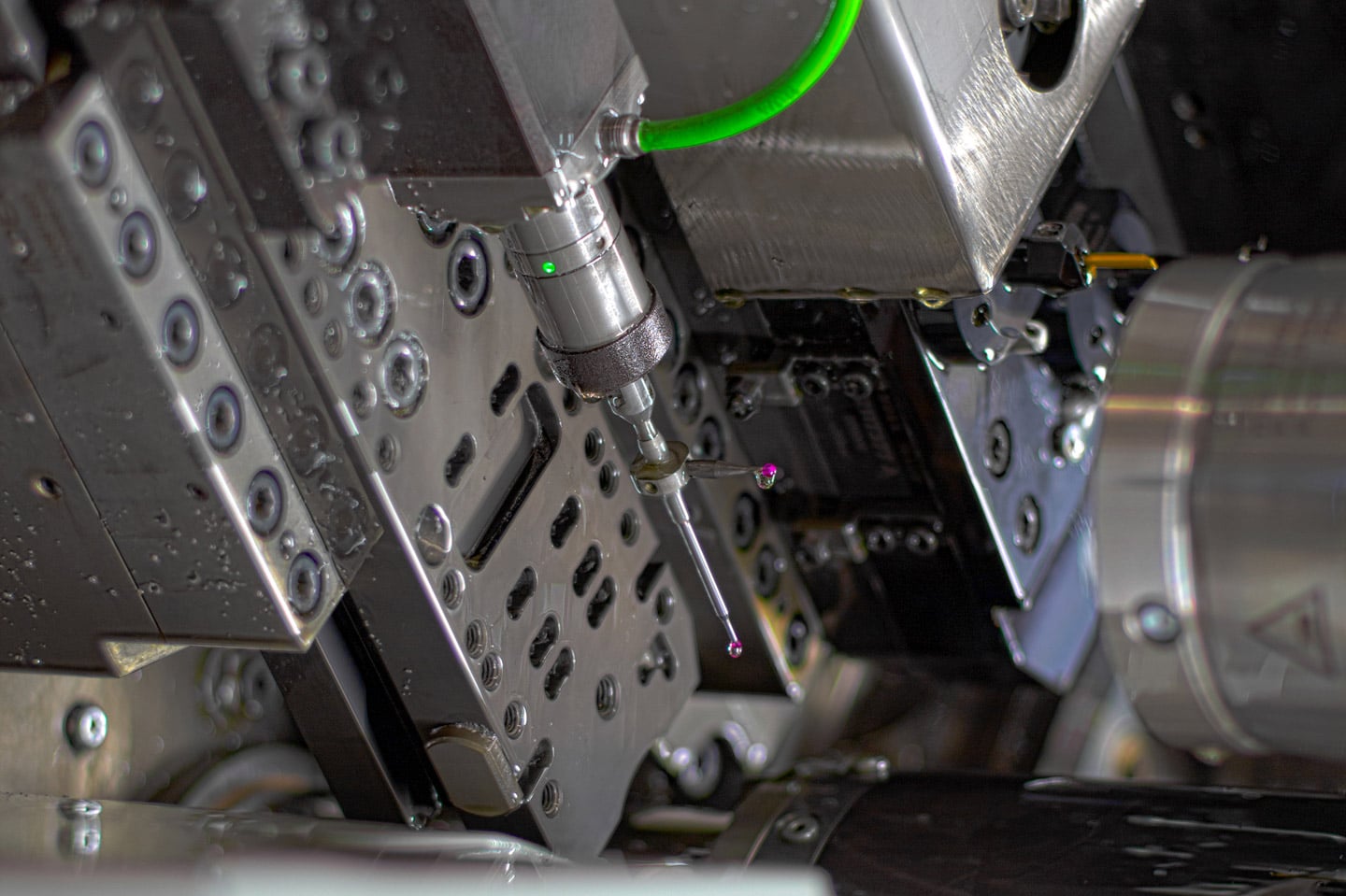

To ensure that the often very small electromagnets from Magnet-Schultz provide good service for many years, their production must be highly precise. This is especially true due to the fact that automation plays a major role in production due to the often enormous quantities involved. In addition to high quality, probes from Blum-Novotest ensure process reliability under the harshest conditions.

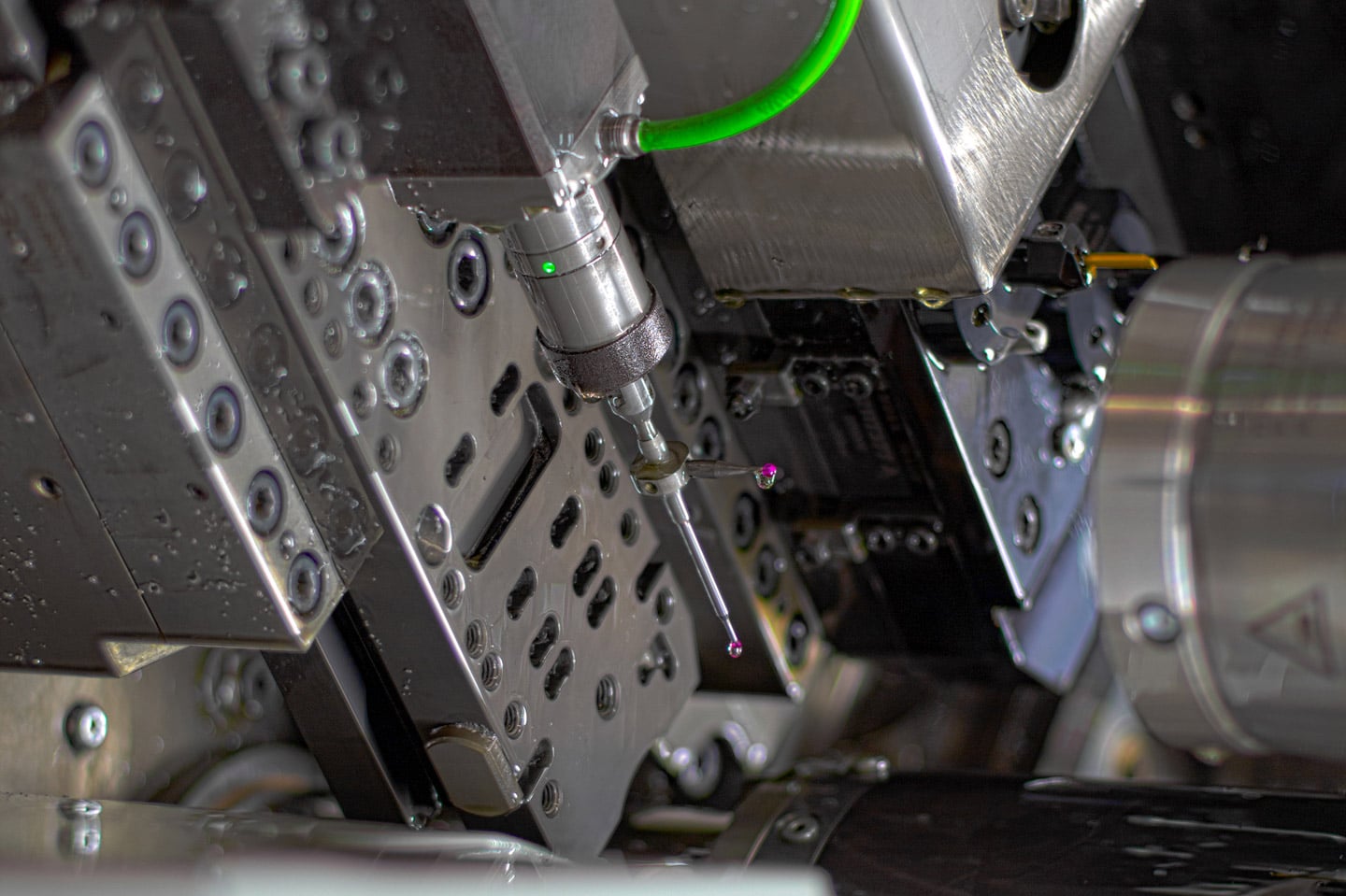

Electromagnets are used wherever electrical signals need to be converted into mechanical movements. These are often linear movements. But Magnet-Schultz from Memmingen (MSM) also produces rotary magnets that perform a precisely defined angular movement. MSM magnets vibrate masses or lock flaps and doors, switch valves and adjust shock absorbers in electronically controlled chassis. The sizes and applications of MSM products vary as much as the batch sizes: The order sizes range from individual products and small series to 10-20 million units per year. The production techniques are just as diverse, ranging from manual assembly to highly automated machining centres. “Our manufacturing specialists rely on automation to a very high degree. This also applies to machining processes for smaller annual quantities so we can fill idle times on the highly automated machines”, explains Production Manager Werner Motz. “The automation solution must be flexible enough, then it’s worth it. BLUM probes are an important piece of this process.”

To ensure that the often very small electromagnets from Magnet-Schultz provide good service for many years, their production must be highly precise. This is especially true due to the fact that automation plays a major role in production due to the often enormous quantities involved. In addition to high quality, probes from Blum-Novotest ensure process reliability under the harshest conditions.

Electromagnets are used wherever electrical signals need to be converted into mechanical movements. These are often linear movements. But Magnet-Schultz from Memmingen (MSM) also produces rotary magnets that perform a precisely defined angular movement. MSM magnets vibrate masses or lock flaps and doors, switch valves and adjust shock absorbers in electronically controlled chassis. The sizes and applications of MSM products vary as much as the batch sizes: The order sizes range from individual products and small series to 10-20 million units per year. The production techniques are just as diverse, ranging from manual assembly to highly automated machining centres. “Our manufacturing specialists rely on automation to a very high degree. This also applies to machining processes for smaller annual quantities so we can fill idle times on the highly automated machines”, explains Production Manager Werner Motz. “The automation solution must be flexible enough, then it’s worth it. BLUM probes are an important piece of this process.”