Blum-Novotest

Products

Blum-Novotest GmbH Fertigungs-Messtechnik

Tool fracture and wear detecting systems

Z-Nano series

Economic solutions for tool breakage detection and tool length measurement in CNC machining centres. Measurements of unrivalled speed and precision under the most adverse manufacturing conditions using a modern measuring mechanism based on a linear working principle and optoelectronic switch signal generation.

Z-Nano series – Reliable tool breakage detection that avoids subsequent damage

Wear-free, optoelectronic signal generation

Z-Nano series – Reliable tool breakage detection that avoids subsequent damage

Wear-free, optoelectronic signal generation

- The trigger signal is generated via shading of a miniature light barrier

- Enables much higher measuring speeds and accuracy than with conventional probes

- Reliable tool breakage detection under the most adverse conditions

- Wear-free with long-term stability

- Ball-bearing precision linear guidance

- The functional principle prevents lateral forces acting on the tool

- Very low measuring force

- Measurement of sensitive and very small tools

- Z-Nano: Hard-wired

- Z-Nano IR: Infrared transmission

- Z-Nano RC: BRC radio technology

- DUO-Mode: Sequential use of 2 infrared measuring systems with one receiver

- Sequential use of up to 6 radio measuring systems with one receiver

- TWIN mode: Simultaneous use of 2 radio measuring systems on one machine

- Very long battery life

TC53-20 | TC63-20

|

Tool measuring and setting unit

Blum-Novotest GmbH Fertigungs-Messtechnik

Tool measuring and setting units

Special tool measurement systems for turning machines and turning/milling centres for adaptation to customer-specific tasks. Precise tool setting and monitoring using innovative, face-geared shark360 measuring mechanism with optoelectronic switch signal generation.

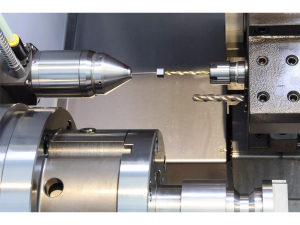

TC53-20 | TC63-20 touch probes - Measure and monitor turning tools in the process

Wear-free, optoelectronic signal generation

TC53-20 | TC63-20 touch probes - Measure and monitor turning tools in the process

Wear-free, optoelectronic signal generation

- The trigger signal is generated via shading of a miniature light barrier

- Enables much higher measuring speeds and accuracy than with conventional probes

- Wear-free with long-term stability

- High-precision, face-geared measuring mechanism

- Defined deflection direction and constant deflection forces

- Extremely fast measurements

- Maximum measuring accuracy even with off-centre probing

- TC53-20: Infrared Transmission

- TC63-20: BRC Radio Technology

- DUO-Mode: Sequential use of 2 infrared measuring systems with one receiver

- Sequential use of up to 6 radio measuring systems with one receiver

- TWIN mode: Simultaneous use of 2 radio measuring systems on one machine

- Very long battery life

TC76

|

Tool measuring and setting unit

Blum-Novotest GmbH Fertigungs-Messtechnik

Tool measuring and setting units

Versatile, hard-wired touch probe for tool and workpiece measurement in highly productive conditions. Precise and fast measurements thanks to innovative, face-geared shark360 measuring mechanism with optoelectronic switch signal generation.

TC76 touch probe – The ideal probe for tool measurement in turning machines

Wear-free, optoelectronic signal generation

TC76 touch probe – The ideal probe for tool measurement in turning machines

Wear-free, optoelectronic signal generation

- The trigger signal is generated via shading of a miniature light barrier

- Enables much higher measuring speeds and accuracy than with conventional probes

- Wear-free with long-term stability

- Face-geared measuring mechanism

- Maximum measuring accuracy even with off-centre probing

- Enables pulling and torsion-exposed measurements

- Constant deflection forces

- No preferred direction

- Extensions and elbows allow for user-specific adaptation

- Cranked styli

- Installation on machine table or wall using optional socket

- Tool measurement using stylus with cube

Z-Nano series

|

Tool measuring and setting unit

Blum-Novotest GmbH Fertigungs-Messtechnik

Tool measuring and setting units

Economic solutions for tool breakage detection and tool length measurement in CNC machining centres. Measurements of unrivalled speed and precision under the most adverse manufacturing conditions using a modern measuring mechanism based on a linear working principle and optoelectronic switch signal generation.

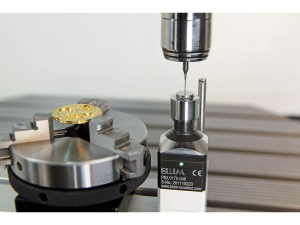

Z-Nano series – Reliable tool breakage detection that avoids subsequent damage

Wear-free, optoelectronic signal generation

Z-Nano series – Reliable tool breakage detection that avoids subsequent damage

Wear-free, optoelectronic signal generation

- The trigger signal is generated via shading of a miniature light barrier

- Enables much higher measuring speeds and accuracy than with conventional probes

- Reliable tool breakage detection under the most adverse conditions

- Wear-free with long-term stability

- Ball-bearing precision linear guidance

- The functional principle prevents lateral forces acting on the tool

- Very low measuring force

- Measurement of sensitive and very small tools

- Z-Nano: Hard-wired

- Z-Nano IR: Infrared transmission

- Z-Nano RC: BRC radio technology

- DUO-Mode: Sequential use of 2 infrared measuring systems with one receiver

- Sequential use of up to 6 radio measuring systems with one receiver

- TWIN mode: Simultaneous use of 2 radio measuring systems on one machine

- Very long battery life

Z-Pico

|

Tool measuring and setting unit

Blum-Novotest GmbH Fertigungs-Messtechnik

Tool measuring and setting units

Hard-wired tool setting probe for drill bit breakage detection and tool length measurement in small machining centres. Measurements of unrivalled speed and precision for micro-tools under the most adverse manufacturing conditions using a modern measuring mechanism based on a linear working principle and optoelectronic switch signal generation.

Z-Pico tool measuring probe – Measure and monitor the smallest tools at up to 2 m/min

Wear-free, optoelectronic signal generation

Z-Pico tool measuring probe – Measure and monitor the smallest tools at up to 2 m/min

Wear-free, optoelectronic signal generation

- The trigger signal is generated via shading of a miniature light barrier

- Enables much higher measuring speeds and accuracy than with conventional probes

- Wear-free with long-term stability

- Ball-bearing precision linear guidance

- The functional principle prevents lateral forces acting on the tool

- Very low measuring force

- Measurement and breakage detection of sensitive and very small tools

- Tool measurement from D = 0.05 mm

- Extremely fast measurement at up to 2 m/min

ZX-Speed Series

|

Tool measuring and setting unit

Blum-Novotest GmbH Fertigungs-Messtechnik

Tool measuring and setting units

Economic solutions for tool setting in length and radius as well as for tool breakage monitoring. Precise and reliable measurements thanks to cutting-edge measuring mechanism technology with optoelectronic switch signal generation.

ZX-Speed Series – Reliable tool measuring probes for a wide variety of machines

Wear-free and optoelectronic signal generation

ZX-Speed Series – Reliable tool measuring probes for a wide variety of machines

Wear-free and optoelectronic signal generation

- The trigger signal is generated via shading of a miniature light barrier

- Enables higher measuring speeds and accuracy than with conventional probes

- Reliable tool setting under the most adverse conditions

- Wear-free with long-term stability

- Precise, non-lobing switching behaviour

- Constant deflection forces

- High-quality latest-generation BLUM measuring mechanism

- No disadvantageous 3-leg principle

- No highly sensitive switching elements

- ZX-Speed: Hardwired

- ZX-Speed IR: Infrared Transmission

- ZX-Speed RC: BRC Radio Technology

- DUO-Mode: Sequential use of 2 infrared measuring systems with one receiver

- Sequential use of up to 6 radio measuring systems with one receiver

- TWIN mode: Simultaneous use of 2 radio measuring systems on one machine

- Very long battery life