Blum-Novotest

Products

Tool monitoring systems

FormControl

|

Tool monitoring systems

Blum-Novotest GmbH Fertigungs-Messtechnik

Tool monitoring systems

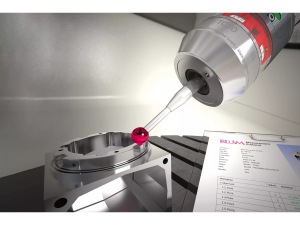

User-friendly software for rapid quality control of contour measurement and standard geometric elements in CNC machining centres. Maximum productivity as well as reduced rejects thanks to control measurements between the machining steps and rework in the original setting.

FormControl measurement software – Measuring at the click of a mouse in CNC milling machines

Measurement with 3- and 5-axis

FormControl measurement software – Measuring at the click of a mouse in CNC milling machines

Measurement with 3- and 5-axis

- Complex measurements in the machining clamping

- Orientation of probe or workpiece at will

- Measurement of relief cuts or oblique borings possible

- 5-axis measurement of what was machined on 5 axes

- No measuring point remains unattainable

- Individual display of measurement values on the PC

- Large number of measuring points via colour bar graphs or colour points

- Output of measurement result in tabular form in CSV format

- Output of clearly structured measuring report incl. customer logo

- Creation of the measurement programme by mouse click

- Collision control

- Creation of the NC programme

- Automatic transfer of the programme to the control system

- Automatic return of the measurement results to FormControl

KinematicsPerfect

|

Tool monitoring systems

Blum-Novotest GmbH Fertigungs-Messtechnik

Tool monitoring systems

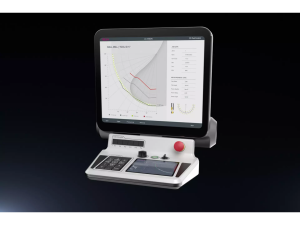

KinematicsPerfect gives you a fully-developed software solution for measuring the kinematics of 4-axis and 5-axis machine tools. The NC-based measuring cycles enable precise checks, documentation and corrections of rotary axes on rotary and swivelling tables.

Detecting and optimising kinematic errors

Checks, Documentation and Corrections

The detection of kinematic errors in the rotary axes involves recording measuring points at a calibration sphere mounted on the machine table. With the aid of the supplied measuring cycles, previously defined points are approached from different probing directions and the spatial deviation calculated. Based on these values, the kinematic parameter tables can be automatically updated, which compensates the spatial error that occurs during swivelling movements.

Maximum Machine Performance

The KinematicsPerfect PC software provides enhanced options for analysing measuring data. It provides a simple way of evaluating the performance of the machine kinematics.

Detecting and optimising kinematic errors

Checks, Documentation and Corrections

- Quickly checks alignment and positioning accuracy based on measurements using a calibration sphere

- Detects mechanical geometrical deviations of the rotary axes as well as bearing damage

- Identification of machine problems caused by incorrect machine settings, collisions or wear

- Verifies the kinematics with/without automatic correction

- Performs measurements during commissioning, service calls or series production based on a thorough inspection of the machine status

The detection of kinematic errors in the rotary axes involves recording measuring points at a calibration sphere mounted on the machine table. With the aid of the supplied measuring cycles, previously defined points are approached from different probing directions and the spatial deviation calculated. Based on these values, the kinematic parameter tables can be automatically updated, which compensates the spatial error that occurs during swivelling movements.

Maximum Machine Performance

- Prevent machining errors caused by the system by adapting the centre of rotation of the rotary axes

- Continuous and long-term checking and logging of machine kinematics

- Maximum machining quality during 5-axis machining with interpolation

- Permanent guarantee of machining quality

- Cost savings thanks to the ability to perform in-house measurements and corrections

- Prevent errors caused by manual measurements of machine accuracy

- Verification of critical machine alignments by definable angle values

- Receive automatic error notifications of measuring values outside of the tolerance

- Rapid reaction to machine crash and checking of machine status

The KinematicsPerfect PC software provides enhanced options for analysing measuring data. It provides a simple way of evaluating the performance of the machine kinematics.

- Enhanced analysis options for optimising the machine kinematics, detecting bearing damage or mechanical geometrical deviations of the rotary axes

- Intuitive, graphic display of measuring results across all axes

- Displays roundness deviations of a table or rotary axis

- Evaluates circular deviation, displays centre drift and individual measurement results

LC-VISION

|

Tool monitoring systems

Blum-Novotest GmbH Fertigungs-Messtechnik

Tool monitoring systems

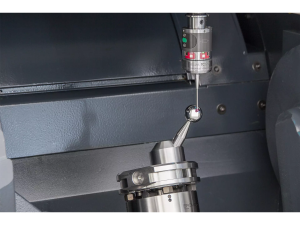

User-friendly measurement and visualisation software for DIGILOG laser measuring systems from BLUM. The application can be used to quickly and easily generate, visualise and evaluate a wide range of measurement tasks in CNC machining centres. The field of application is not only limited to the topic of tool measurement, but also includes a reliable assessment of the motor spindle quality.

LC-VISION – More than just visualisation

Even the basic functions of LC VISION offer real added value, as current measurement processes, important system information and data for preventive maintenance can be called up quickly and easily on the control screen. Special technology cycles can also be easily enabled.

Tool Dashboard

In addition to the standard functions, the technology cycles "ToolControl Advanced", "SpindleControl" and "OscillationControl" are currently available. These options are next-generation high-tech features.

LC-VISION – More than just visualisation

Even the basic functions of LC VISION offer real added value, as current measurement processes, important system information and data for preventive maintenance can be called up quickly and easily on the control screen. Special technology cycles can also be easily enabled.

Tool Dashboard

- Overview of all measurements performed with the aid of BLUM NC cycles

- Visualisation of measurement history and wear trend of the respective tools

- Shows important system data

- Manual activation of laser status functions

- Display of preventive maintenance information

- Display of the activated technology cycles

- Activation of technology cycles via activation code

In addition to the standard functions, the technology cycles "ToolControl Advanced", "SpindleControl" and "OscillationControl" are currently available. These options are next-generation high-tech features.

measureXpert App

|

Tool monitoring systems

Blum-Novotest GmbH Fertigungs-Messtechnik

Tool monitoring systems

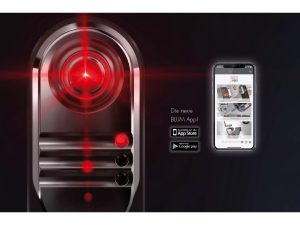

Using the app makes it quick and easy to generate cycle calls for many control types and BLUM measuring systems. measureXpert is available free of charge for Android, iOS and Windows.

Become a measureXpert!

The user is guided step-by-step from the measuring task to the correct cycle call. It has never been easier to use our measuring systems. The app is available in many languages.

By using measureXpert you can generate cycle calls quick and easy for

Become a measureXpert!

The user is guided step-by-step from the measuring task to the correct cycle call. It has never been easier to use our measuring systems. The app is available in many languages.

By using measureXpert you can generate cycle calls quick and easy for

- Laser measuring systems

- Workpiece touch probes

- Tool setting probes

Quickstart

|

Tool monitoring systems

Blum-Novotest GmbH Fertigungs-Messtechnik

Tool monitoring systems

User-friendly software for workpiece measurement and temperature compensation with BLUM touch probes. Comprehensive calibration cycles, measuring cycles for geometric standard elements as well as customer-specific solutions for maximum in-process reliability.

Quickstart cycles – The most effective way to use BLUM touch probes

Intelligent measuring cycles

GUI - Graphical User Interface

Quickstart cycles – The most effective way to use BLUM touch probes

Intelligent measuring cycles

- User-friendly subroutines for machine control*

- They can be used both for workpiece referencing as well as for measuring during the production process

- Optimum exploitation of potential of the BLUM touch probes

GUI - Graphical User Interface

- Optionally available software components

- User-friendly operation via input mask

- Self-explanatory by graphical presentation

- Call via soft keys

- Optionally available software components

- NC-based measuring cycles for measurement of the Kinematics of 4 or 5 axes milling machines

- Measurement of the accuracy and correction of the kinematics of 1 or 2 rotary axes

- Identification of machine problems caused by incorrect machine settings, collisions or wear

- Quick check of the aligning- and positioning accuracy by measurement of a calibration sphere