Vertical and horizontal connectivity, digital engineering, economic production of very small batch sizes – without software, these core characteristics of Industry 4.0 would be inconceivable. Even today, software contributes a great deal to the added value created by machines, while in the factory of the future it supplies the necessary intelligence for modular, mobile and connected production components. Using its Connected Automation portfolio, Bosch Rexroth will be demonstrating how state-of-the-art software affects competitiveness and time-to-market at the SPS IPC Drives.

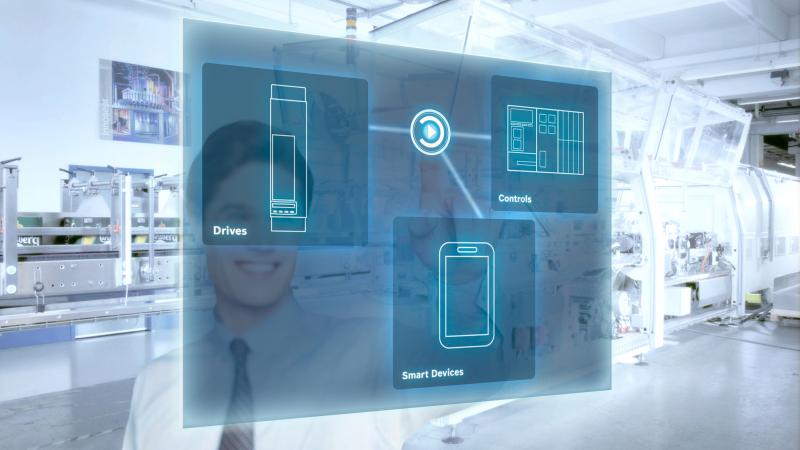

Characteristic of Rexroth software in all areas is open architecture with Open Core Interface, which allows direct access to control functions and lays the foundation for highly efficient engineering. That's because controllers, drives and peripherals can be consistently and uniformly configured and controlled within the intuitively designed IndraWorks software environment – based on current Windows technologies and comprehensive wizards. Thanks to various function modules and templates, standard applications can be created simply by parameterizing. State-of-the-art tools and languages are available for explicit programming. The virtual commissioning of machines and plants makes testing safer and shortens the time-to-market. The automation solutions from Bosch Rexroth are becoming IoT-ready thanks to the integrated i4.0 standard OPC-UA.

In the field of CNC systems, the new version 14 of the MTX provides new capabilities for multi-technological machining with up to 60 channels and 250 axes. A variety of standard applications is already prepared, including bending, turning, milling, grinding, punching/nibbling, jet cutting or rotary transferring. Innovative functions make even industrial 3D printing useful for series production of small batch sizes. Customer-specific functions can also be added via the open architecture.

Version 14 of the Motion-Control system MLC from Bosch Rexroth also contains considerable potential for standardization in addition to many prepared standard applications. Because it includes ready-to-use function toolkits for robotics, PLC, safety and integrated servo functions, in addition to comprehensive motion control, which means the control platforms for packaging, production and other industries can be standardized. For complex applications, the Generic Application Template (GAT) function toolkit reduces engineering efforts by up to 60 percent by automatically generating modular machine programs based on the IEC 61131-3 and PLCopen PLC standards. With the CamBuilder function toolkit electronic cams can be graphically created and simulated. After the successful simulation, the function blocks for the control are automatically generated, thereby greatly reducing errors in the manual creation process.

A further innovation in the Connected portfolio is that function toolkits, such as the Open Core Interface, allow PLC (Programmable Logic Control) to become ILC (IoT Logic Control). The IoT-enabled PLC system ILC version 14 addresses special machine construction, logistics plants and general automation and connects them easily and highly connectively with the Internet of Things. In addition to Sercos, ProfiNET and EthernetIP, ILC software version 14 continues to feature a new EtherCAT softmaster for controlling I/O components.

Like the MLC and ILC software, the IoT Gateway V2 is purely software based and can therefore not only be used on the embedded control XM but also on industrial PCs, for example on the new PR generation of IPCs from Bosch Rexroth. In addition to connectivity, the software is also crucial for cross-site manageability – with the IoT Gateway, the new device portal – a joint development by Rexroth and Bosch Connected Industry –allows for centralized and secure management of distributed infrastructures.

The drive system software MPx20 also contributes to fast and cost-optimized new machine development. It permits continuous connectivity within the 100 W to 4 MW power range, integrates safety and intelligence functions such as vibration damping, and accelerates the development and testing of control programs thanks to drive-internal axle simulation.

Germany

Germany