CHIRON Group SE

Videos

PERFORMANCE MEETS PRECISION

CHIRON FZ 16 S five axis with HSK-A100 I Benefits (EN)

2020-07-15 10:33 | 81 calls

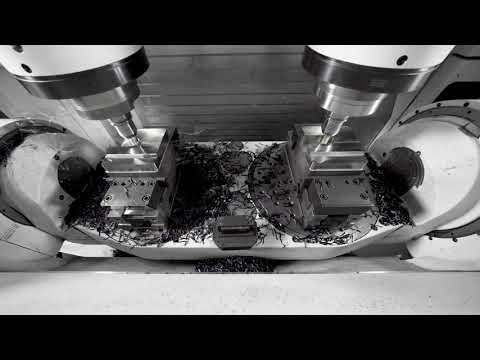

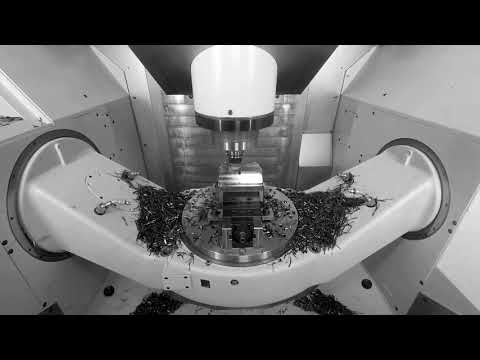

The demanding machining applications in the aviation industry, where components are mostly machined from a solid block, require machining centers that combine optimum milling performance with maximum precision.

The new CHIRON FZ 16 S five axis with HSK-A100 is tailored to the high requirements of this industry. It has a powerful main spindle with a torque of 400 Nm and is predestined for machining difficult structural components made from titanium or nickel-based alloys like INCONEL. The particularly large HSK-A100 interface and the proven moving gantry design, which ensures high static and dynamic rigidity, form the basis for particularly high machining rates and machining very deep cavities. The powerful drives of the machining center provide the required dynamics. The new FZ 16 S five axis with HSK-A100 also impresses in terms of precision thanks to a robust basic design and particularly high thermal stability.

The new CHIRON FZ 16 S five axis with HSK-A100 is tailored to the high requirements of this industry. It has a powerful main spindle with a torque of 400 Nm and is predestined for machining difficult structural components made from titanium or nickel-based alloys like INCONEL. The particularly large HSK-A100 interface and the proven moving gantry design, which ensures high static and dynamic rigidity, form the basis for particularly high machining rates and machining very deep cavities. The powerful drives of the machining center provide the required dynamics. The new FZ 16 S five axis with HSK-A100 also impresses in terms of precision thanks to a robust basic design and particularly high thermal stability.