COSCOM Unveils New Module for Optimizing CAD Tool Data

Since 1978, COSCOM Computer GmbH has been a leading software company offering successful products and services in the field of CNC-based manufacturing digitalization. As an established EMO exhibitor, COSCOM is proud to be part of this year’s “AI + Digitalization” joint stand. “Explaining our solutions for increasing efficiency and reducing costs in just a few words is not easy. In addition to digital process optimization, we also offer IT security solutions for connecting machine tools, which can help prevent production downtime due to cyberattacks,” explains Managing Director Christian Erlinger.

COSCOM offers comprehensive solutions from a single source:

• Digital tool database: creation of the digital twin without redundant data storage

• Integration of ERP, CAM, simulation, and storage systems into the COSCOM Eco-System

• Cybersecurity, network segmentation, and mobile applications

With an experienced team of process consultants, sales experts, and technicians, EMO visitors will have the opportunity to discover new approaches for optimizing complex CNC machining processes.

New TCI Data Preparation Module for Intelligent CAD Data Processing

The COSCOM ToolDIRECTOR VM (=Virtual Machining) is a modular software solution that provides comprehensive tool management support. The first step involves transforming CAD data from various tool manufacturers as well as in-house tool designs for CNC machines to create a digital twin. The software supports CAD data from numerous systems such as AutoCAD, Autodesk Inventor, Dassault Systèmes CATIA V5, SOLIDWORKS, Siemens NX, and many more. ToolDIRECTOR VM delivers complete data for machine simulation and collision control within the digital twin application.

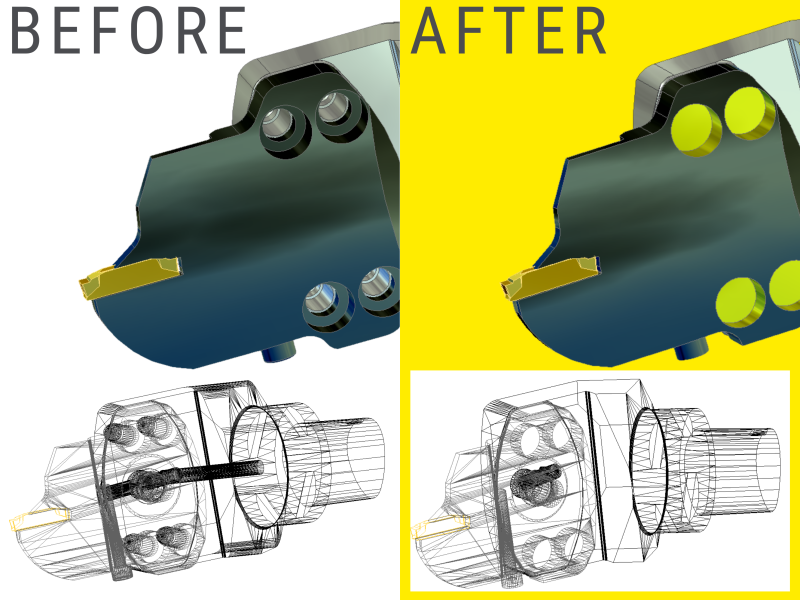

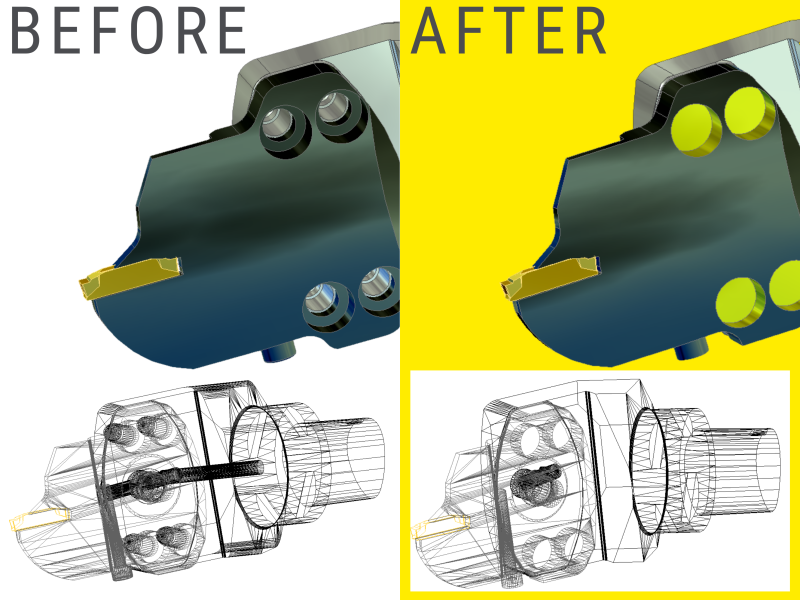

One major challenge for digital twin applications has been the massive data volume. The large number of fine geometric details—such as internal structures—significantly affects application performance. While some geometries must be retained for collision checking and similar processes, many details (e.g., the internal structure of a bore) are not essential for the digital twin. Reducing such fine details leads to data minimization. This is precisely where the new module, developed by COSCOM in collaboration with long-term technology partner Spatial Corp comes into play. COSCOM leverages several Software Development Kits (SDKs) from Spatial Corp, including the 3D InterOp SDK for reliable CAD data translation. More recently, COSCOM have integrated the Data Prep add-on to 3D InterOp, which forms the foundation of this breakthrough by enabling significant data reduction and time savings.

The result: an automatic one-click solution for CAD data simplification within ToolDIRECTOR VM, specifically in the Tooldata Cooperation Interface (TCI) – the central interface for graphical data preparation. “With a single click, CAD data can be selectively reduced without losing relevant information. This allows our customers to save significant time not only in data preparation but also during tool simulation and collision checks,” summarizes Managing Director Knut Mersch, responsible for COSCOM software development. The new TCI Data Preparation module will be demonstrated live for the first time at EMO at the Spatial Corp booth (Hall 6, Stand C37) and is now available.

Get free EMO tickets: Teilnahme & Tickets

Since 1978, COSCOM Computer GmbH has been a leading software company offering successful products and services in the field of CNC-based manufacturing digitalization. As an established EMO exhibitor, COSCOM is proud to be part of this year’s “AI + Digitalization” joint stand. “Explaining our solutions for increasing efficiency and reducing costs in just a few words is not easy. In addition to digital process optimization, we also offer IT security solutions for connecting machine tools, which can help prevent production downtime due to cyberattacks,” explains Managing Director Christian Erlinger.

COSCOM offers comprehensive solutions from a single source:

• Digital tool database: creation of the digital twin without redundant data storage

• Integration of ERP, CAM, simulation, and storage systems into the COSCOM Eco-System

• Cybersecurity, network segmentation, and mobile applications

With an experienced team of process consultants, sales experts, and technicians, EMO visitors will have the opportunity to discover new approaches for optimizing complex CNC machining processes.

New TCI Data Preparation Module for Intelligent CAD Data Processing

The COSCOM ToolDIRECTOR VM (=Virtual Machining) is a modular software solution that provides comprehensive tool management support. The first step involves transforming CAD data from various tool manufacturers as well as in-house tool designs for CNC machines to create a digital twin. The software supports CAD data from numerous systems such as AutoCAD, Autodesk Inventor, Dassault Systèmes CATIA V5, SOLIDWORKS, Siemens NX, and many more. ToolDIRECTOR VM delivers complete data for machine simulation and collision control within the digital twin application.

One major challenge for digital twin applications has been the massive data volume. The large number of fine geometric details—such as internal structures—significantly affects application performance. While some geometries must be retained for collision checking and similar processes, many details (e.g., the internal structure of a bore) are not essential for the digital twin. Reducing such fine details leads to data minimization. This is precisely where the new module, developed by COSCOM in collaboration with long-term technology partner Spatial Corp comes into play. COSCOM leverages several Software Development Kits (SDKs) from Spatial Corp, including the 3D InterOp SDK for reliable CAD data translation. More recently, COSCOM have integrated the Data Prep add-on to 3D InterOp, which forms the foundation of this breakthrough by enabling significant data reduction and time savings.

The result: an automatic one-click solution for CAD data simplification within ToolDIRECTOR VM, specifically in the Tooldata Cooperation Interface (TCI) – the central interface for graphical data preparation. “With a single click, CAD data can be selectively reduced without losing relevant information. This allows our customers to save significant time not only in data preparation but also during tool simulation and collision checks,” summarizes Managing Director Knut Mersch, responsible for COSCOM software development. The new TCI Data Preparation module will be demonstrated live for the first time at EMO at the Spatial Corp booth (Hall 6, Stand C37) and is now available.

Get free EMO tickets: Teilnahme & Tickets