Tool Master Data Import: Direct Communication Between Manufacturer and User Becomes Reality

Tool master data for milling and turning machines form the foundation for an end-to-end tool management process. Users place high demands on the quality and informational content of DXF and STEP tool models as well as technological data. After all, they serve as the basis for key digitalization processes—from CAD/CAM and machine simulation to the control of logistical workflows in manufacturing.

To make the creation of tool master data in a COSCOM tool management system as simple as possible, COSCOM developed an efficient solution. The pilot project involved the milling tool manufacturer Aura Tools GmbH and the manufacturing company HETEC GmbH, both located in Breidenbach (Hesse, Germany).

The business relationship between HETEC and Aura Tools dates back to 2007. HETEC operates various 5-axis machining centers from manufacturers GROB and Hermle. More than two thirds of the tools used come from Aura Tools and play a key role in the production of tool, mold, and machine components. Starting in 2016, HETEC began automating its machining centers. At the end of last year, COSCOM was awarded the contract for automated tool management.

Background – Manual Data Processing with High Time Requirements

In the ToolDIRECTOR VM (= Virtual Machining) tool management software, all relevant tool data can be stored centrally. API interfaces also enable connections to other systems such as CAM, machine simulation, ERP, and PLM. Until now, data import was carried out using standards such as DIN 4000, ISO 13399, GTC packages, or by importing geometry data as STEP files. These are generally meaningful and well-established methods for exchanging basic data. However, as soon as user-specific or technologically enhanced information — crucial for optimal manufacturing — is required, these standards reach their limits or require complex extensions and bureaucratic coordination efforts.

Aura Tools deliberately relies on native CAM formats with maximum information content. Managing Director Markus Künkler explains:

“Standard formats or pure geometry data are technically unable to represent the scope of complex tool and process data we aim to provide, especially validated cutting data reference values. That is why we strive to deliver formats directly for the end-user system. For geometry data, we limit ourselves to simple formats such as DXF, which can fully represent our rotationally symmetrical tools.”

“The DXF files were obtained via the Aura Tools tool configurator, manually converted into STEP rotational bodies, and then had to be edited, aligned, parameterized, and supplemented with cutting values in COSCOM ToolDIRECTOR VM,” recalls Tom Herhaus, Managing Director of HETEC, describing the previous situation. This process was initially common practice in order to adapt datasets to the respective export interfaces (CAD/CAM systems, simulation systems, etc.) in the required system-specific formats.

Direct Data Transfer – Fast and Error-Free

The challenge for all partners was obvious: How can the complete, validated data from Aura Tools be transferred directly into COSCOM’s tool management system (ToolDIRECTOR VM) without the duplicate interpretation errors inherent in generic standards?

COSCOM was aware that users require tool data for different data needs. For this reason, the company invested in further developing the Tool Cooperation Interface (TCI). TCI ensures centralized graphical processing and standardized data creation and is an integral part of ToolDIRECTOR VM.

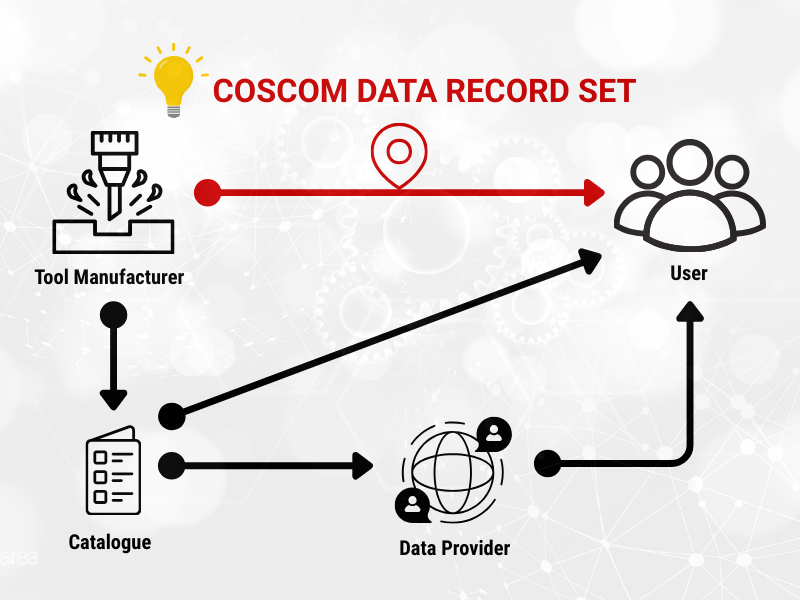

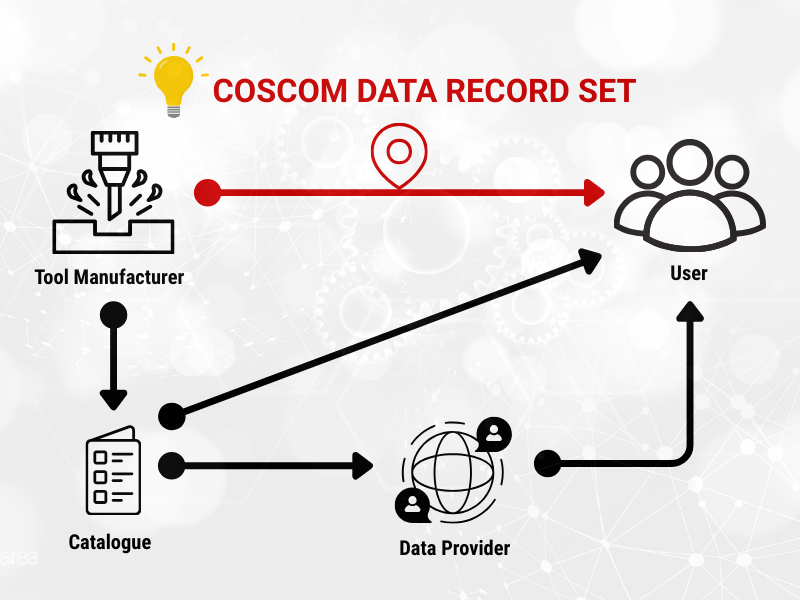

“We managed to enrich a COSCOM Data Record Set (complete tool datasets provided by the tool manufacturer) with a wide range of specific information. The COSCOM Data Record Set is a native format and can therefore be used for all target systems, even though these systems require different formats for tool information,” explains Christian Erlinger, Managing Director of COSCOM.

One example: From the COSCOM Data Record Set, data can be quickly transferred to CAM system 1, which expects a parameterized cutting-edge geometry—since this information has already been stored in the tool management system without manual effort. At the same time, CAM system 2, which always expects a graphical cutting element with a center cut, is supplied automatically, without requiring additional data preparation.

Until now, however, this format had not been supported by external manufacturers.

Since Aura Tools is accustomed to working directly with native formats and deliberately avoids third-party data preparation or standard formats in order to ensure data currency and accuracy, a direct collaboration was the logical choice.

Minimal Effort, Maximum Benefit

Addressing the effort required to generate the COSCOM Data Record Set, Markus Künkler explains:

“COSCOM documented the technical specification of this format. Our main effort consisted of implementing software to map our internal data structure to the external COSCOM format. After only a few coordination steps, the complete tool data could be transferred into operational use. The major advantage of the COSCOM Data Record Set is that it integrates generic geometry data and all COSCOM-specific parameters — previously added manually — into a single dataset. This enables automated processing in ToolDIRECTOR VM and direct use for further transformations.”

Tom Herhaus also emphasizes the simplicity of the process:

“Apart from a few minor adjustments to definitions and classifications, the tool master data import was fully automated and took only a few minutes.”

His conclusion: “Importing all geometry data with correct range definitions and cutting values not only saves time, but also enables uncomplicated use by all users. In addition, error-free transfer of all data is ensured.”

Both Aura Tools and HETEC explicitly recommend the use of direct interfaces such as the COSCOM Data Record Set. Ultimately, the data strategy decision lies with the user and their specific requirements.

As a bridge builder, COSCOM plans to enable additional tool manufacturers to access this approach in the future — with the goal of sustainably promoting direct and efficient data communication in the manufacturing industry.

Tool master data for milling and turning machines form the foundation for an end-to-end tool management process. Users place high demands on the quality and informational content of DXF and STEP tool models as well as technological data. After all, they serve as the basis for key digitalization processes—from CAD/CAM and machine simulation to the control of logistical workflows in manufacturing.

To make the creation of tool master data in a COSCOM tool management system as simple as possible, COSCOM developed an efficient solution. The pilot project involved the milling tool manufacturer Aura Tools GmbH and the manufacturing company HETEC GmbH, both located in Breidenbach (Hesse, Germany).

The business relationship between HETEC and Aura Tools dates back to 2007. HETEC operates various 5-axis machining centers from manufacturers GROB and Hermle. More than two thirds of the tools used come from Aura Tools and play a key role in the production of tool, mold, and machine components. Starting in 2016, HETEC began automating its machining centers. At the end of last year, COSCOM was awarded the contract for automated tool management.

Background – Manual Data Processing with High Time Requirements

In the ToolDIRECTOR VM (= Virtual Machining) tool management software, all relevant tool data can be stored centrally. API interfaces also enable connections to other systems such as CAM, machine simulation, ERP, and PLM. Until now, data import was carried out using standards such as DIN 4000, ISO 13399, GTC packages, or by importing geometry data as STEP files. These are generally meaningful and well-established methods for exchanging basic data. However, as soon as user-specific or technologically enhanced information — crucial for optimal manufacturing — is required, these standards reach their limits or require complex extensions and bureaucratic coordination efforts.

Aura Tools deliberately relies on native CAM formats with maximum information content. Managing Director Markus Künkler explains:

“Standard formats or pure geometry data are technically unable to represent the scope of complex tool and process data we aim to provide, especially validated cutting data reference values. That is why we strive to deliver formats directly for the end-user system. For geometry data, we limit ourselves to simple formats such as DXF, which can fully represent our rotationally symmetrical tools.”

“The DXF files were obtained via the Aura Tools tool configurator, manually converted into STEP rotational bodies, and then had to be edited, aligned, parameterized, and supplemented with cutting values in COSCOM ToolDIRECTOR VM,” recalls Tom Herhaus, Managing Director of HETEC, describing the previous situation. This process was initially common practice in order to adapt datasets to the respective export interfaces (CAD/CAM systems, simulation systems, etc.) in the required system-specific formats.

Direct Data Transfer – Fast and Error-Free

The challenge for all partners was obvious: How can the complete, validated data from Aura Tools be transferred directly into COSCOM’s tool management system (ToolDIRECTOR VM) without the duplicate interpretation errors inherent in generic standards?

COSCOM was aware that users require tool data for different data needs. For this reason, the company invested in further developing the Tool Cooperation Interface (TCI). TCI ensures centralized graphical processing and standardized data creation and is an integral part of ToolDIRECTOR VM.

“We managed to enrich a COSCOM Data Record Set (complete tool datasets provided by the tool manufacturer) with a wide range of specific information. The COSCOM Data Record Set is a native format and can therefore be used for all target systems, even though these systems require different formats for tool information,” explains Christian Erlinger, Managing Director of COSCOM.

One example: From the COSCOM Data Record Set, data can be quickly transferred to CAM system 1, which expects a parameterized cutting-edge geometry—since this information has already been stored in the tool management system without manual effort. At the same time, CAM system 2, which always expects a graphical cutting element with a center cut, is supplied automatically, without requiring additional data preparation.

Until now, however, this format had not been supported by external manufacturers.

Since Aura Tools is accustomed to working directly with native formats and deliberately avoids third-party data preparation or standard formats in order to ensure data currency and accuracy, a direct collaboration was the logical choice.

Minimal Effort, Maximum Benefit

Addressing the effort required to generate the COSCOM Data Record Set, Markus Künkler explains:

“COSCOM documented the technical specification of this format. Our main effort consisted of implementing software to map our internal data structure to the external COSCOM format. After only a few coordination steps, the complete tool data could be transferred into operational use. The major advantage of the COSCOM Data Record Set is that it integrates generic geometry data and all COSCOM-specific parameters — previously added manually — into a single dataset. This enables automated processing in ToolDIRECTOR VM and direct use for further transformations.”

Tom Herhaus also emphasizes the simplicity of the process:

“Apart from a few minor adjustments to definitions and classifications, the tool master data import was fully automated and took only a few minutes.”

His conclusion: “Importing all geometry data with correct range definitions and cutting values not only saves time, but also enables uncomplicated use by all users. In addition, error-free transfer of all data is ensured.”

Both Aura Tools and HETEC explicitly recommend the use of direct interfaces such as the COSCOM Data Record Set. Ultimately, the data strategy decision lies with the user and their specific requirements.

As a bridge builder, COSCOM plans to enable additional tool manufacturers to access this approach in the future — with the goal of sustainably promoting direct and efficient data communication in the manufacturing industry.