From new grinding machines to CNC precision robotics: Danobat at EMO

Staying true to its innovative spirit, Danobat will also present groundbreaking robotic solutions that optimize existing processes and open new production possibilities: the most accurate, stiff, and stable CNC robot on the market is going to perform real-time machining. All these innovations will be presented under the slogan “Moments We Build Together” at Hall 11, Stand F60, from September 22 to 26.

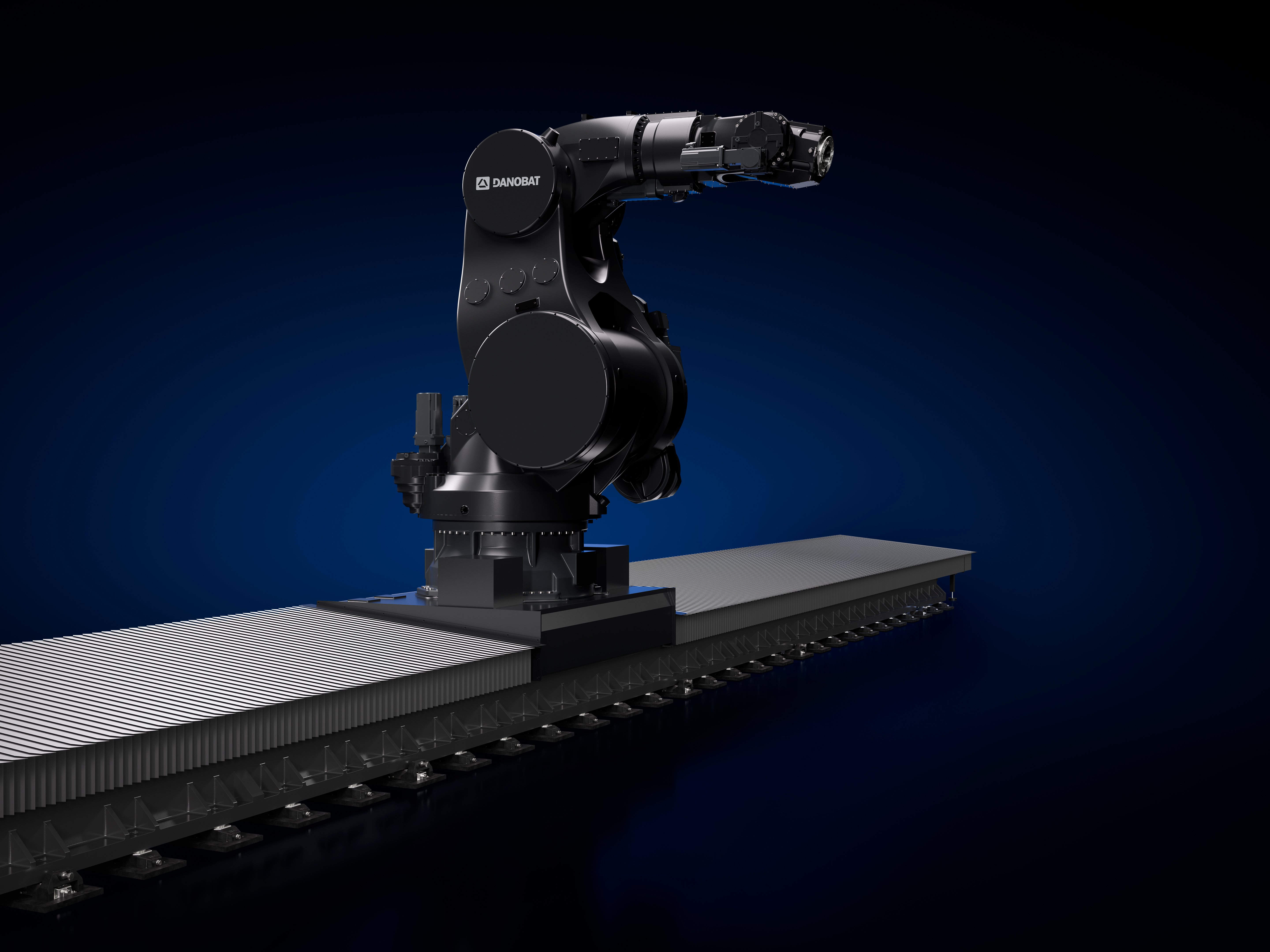

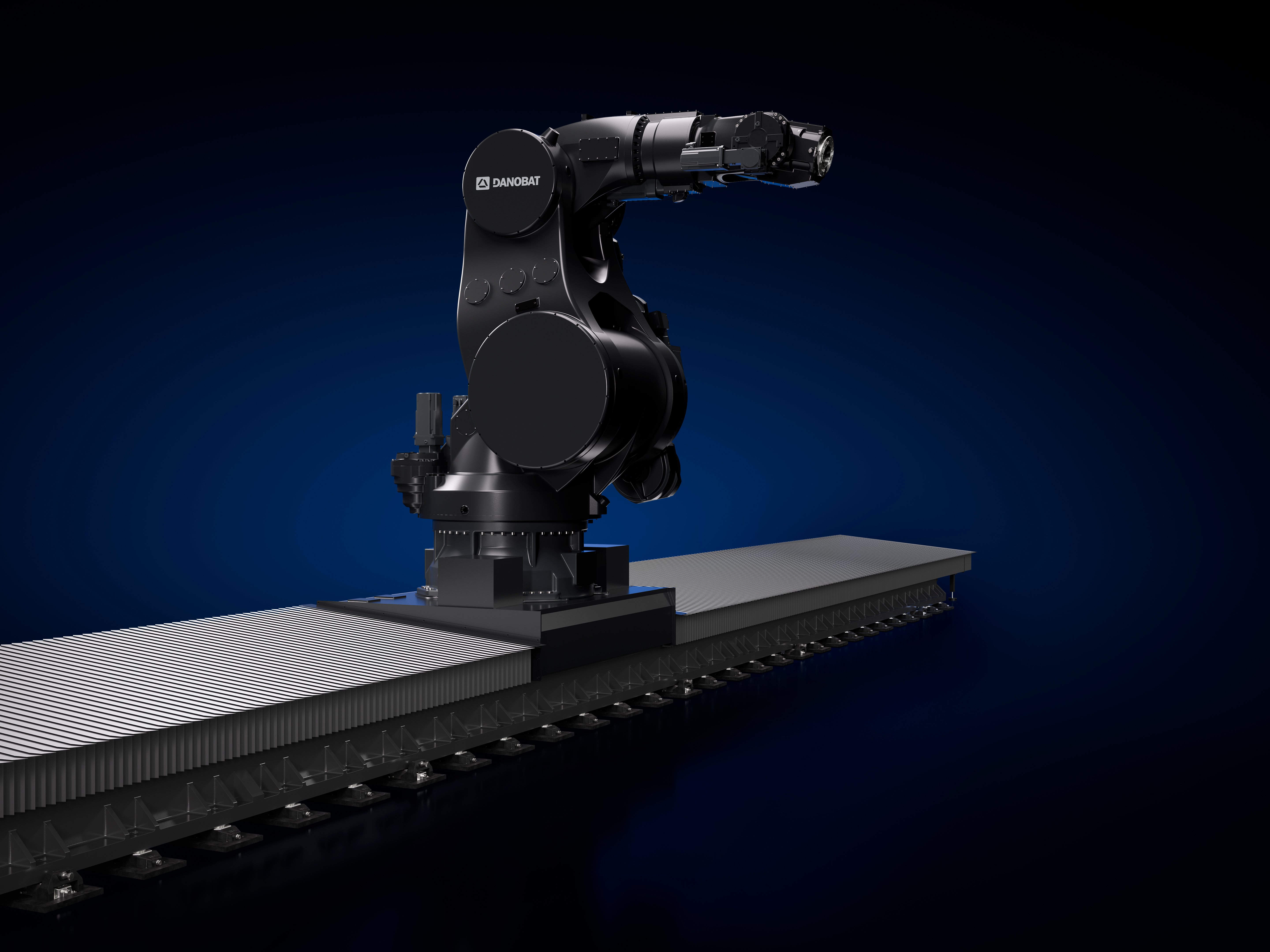

The most precise CNC robot series

Earlier this year, Danobat made a bold leap into CNC precision robotics with dBOT, an innovative robot range built for operations that demand precision and dynamic performance. These groundbreaking robots set new industry standards by combining the flexibility of a robot with the stiffness, stability, and accuracy of a machine tool. No other robot on the market offers this performance with 3 times higher accuracy, 10 times better stiffness, and zero backlash — making it the ideal choice even for complex machining and high-precision manufacturing. At EMO, dBOT will showcase its capabilities with real-time machining.

The new IRD series

Overbeck’s IRD series has long set the standard for high-precision internal and radius grinding, even on tough materials like ceramics and carbide. As manufacturing shifts toward more agile production, the IRD has been completely redesigned to meet new demands.

Precise, flexible, and automation-ready, the new IRD performs internal, external, face, radius, and non-round grinding in a single setup. It stands alone in the market as the only machine to integrate both radius and non-round processes within a single software platform. Designed for high-precision applications in aerospace, toolmaking, and mold and die sectors, it easily handles complex geometries and delivers superior surface finishes.

At EMO Hannover, Overbeck will showcase the new IRD-300 with an integrated robot — offering a footprint 40% smaller than alternative machines.

CGX: Compact and versatile grinding machine

The new CGX delivers versatility in a compact 13 sqm footprint: it handles OD, ID, face, and non-round grinding — among other operations — on parts up to 1,800 mm in length, 540 mm in diameter, and 500 kg in weight, making it the only grinder in its class with such a big part capacity in a compact design.

At EMO, the CGX will be equipped with an integrated MDM gauge for in- and post-process measurement, allowing real-time control of multiple diameters without interruption. Initially developed for large parts on our HG grinding machines, the MDM has proved highly effective in ensuring tight tolerances. The new MDM-100 brings that precision to smaller components (5–125 mm) and includes key improvements over previous versions. It’s an ideal solution for manufacturers working with multiple references or parts with varying diameters and continuous or interrupted surfaces — especially valuable when tight tolerances must be measured on small parts.

Estarta: Expert results in centerless from the first part

Historically, achieving top results in a centerless grinding relied on the operator’s knowledge. Estarta changes that paradigm by delivering expert-level results from the very first part.

Designed for fast changeovers, full ergonomics, and automatic loading in just 3.5 seconds, Estarta also includes OD and face grinding capabilities thanks to its angular configuration — ensuring burn-free results even in high-throughput environments. Its fully electric design, with no hydraulics, minimizes energy use and simplifies maintenance, making it the perfect fit for high-volume operations.

Same Mikroturn, more capabilities

Hembrug’s Mikroturn ultra-precision hard turning lathe now integrates superfinishing and tool and workpiece measuring systems inside the machine, achieving surface finishes of Ra 0.05 µm and sub-micron profile accuracy. This all-in-one solution eliminates the need for external inspection or additional process steps. Engineered for complex threaded profiles — including gothic, round, planetary, and whitworth — the Mikroturn delivers micron-accurate parts from the very first part.

About Danobat

Danobat is a global leader in designing and manufacturing advanced, precise, high-value-added and engineered-to-order manufacturing solutions.

The company encompasses three renowned brands: Danobat, Overbeck and Hembrug. With over seven decades of expertise, Danobat specializes in creating innovative equipment, including precision grinding machines, lathes, and robotic systems for machining. Overbeck, with a century of proven excellence, stands as a distinguished German manufacturer focused on high-precision internal grinding machines. Hembrug, the leader in ultra precision hard turning lathes and hybrid machines, brings its fine turning and grinding capabilities to the forefront.

Staying true to its innovative spirit, Danobat will also present groundbreaking robotic solutions that optimize existing processes and open new production possibilities: the most accurate, stiff, and stable CNC robot on the market is going to perform real-time machining. All these innovations will be presented under the slogan “Moments We Build Together” at Hall 11, Stand F60, from September 22 to 26.

The most precise CNC robot series

Earlier this year, Danobat made a bold leap into CNC precision robotics with dBOT, an innovative robot range built for operations that demand precision and dynamic performance. These groundbreaking robots set new industry standards by combining the flexibility of a robot with the stiffness, stability, and accuracy of a machine tool. No other robot on the market offers this performance with 3 times higher accuracy, 10 times better stiffness, and zero backlash — making it the ideal choice even for complex machining and high-precision manufacturing. At EMO, dBOT will showcase its capabilities with real-time machining.

The new IRD series

Overbeck’s IRD series has long set the standard for high-precision internal and radius grinding, even on tough materials like ceramics and carbide. As manufacturing shifts toward more agile production, the IRD has been completely redesigned to meet new demands.

Precise, flexible, and automation-ready, the new IRD performs internal, external, face, radius, and non-round grinding in a single setup. It stands alone in the market as the only machine to integrate both radius and non-round processes within a single software platform. Designed for high-precision applications in aerospace, toolmaking, and mold and die sectors, it easily handles complex geometries and delivers superior surface finishes.

At EMO Hannover, Overbeck will showcase the new IRD-300 with an integrated robot — offering a footprint 40% smaller than alternative machines.

CGX: Compact and versatile grinding machine

The new CGX delivers versatility in a compact 13 sqm footprint: it handles OD, ID, face, and non-round grinding — among other operations — on parts up to 1,800 mm in length, 540 mm in diameter, and 500 kg in weight, making it the only grinder in its class with such a big part capacity in a compact design.

At EMO, the CGX will be equipped with an integrated MDM gauge for in- and post-process measurement, allowing real-time control of multiple diameters without interruption. Initially developed for large parts on our HG grinding machines, the MDM has proved highly effective in ensuring tight tolerances. The new MDM-100 brings that precision to smaller components (5–125 mm) and includes key improvements over previous versions. It’s an ideal solution for manufacturers working with multiple references or parts with varying diameters and continuous or interrupted surfaces — especially valuable when tight tolerances must be measured on small parts.

Estarta: Expert results in centerless from the first part

Historically, achieving top results in a centerless grinding relied on the operator’s knowledge. Estarta changes that paradigm by delivering expert-level results from the very first part.

Designed for fast changeovers, full ergonomics, and automatic loading in just 3.5 seconds, Estarta also includes OD and face grinding capabilities thanks to its angular configuration — ensuring burn-free results even in high-throughput environments. Its fully electric design, with no hydraulics, minimizes energy use and simplifies maintenance, making it the perfect fit for high-volume operations.

Same Mikroturn, more capabilities

Hembrug’s Mikroturn ultra-precision hard turning lathe now integrates superfinishing and tool and workpiece measuring systems inside the machine, achieving surface finishes of Ra 0.05 µm and sub-micron profile accuracy. This all-in-one solution eliminates the need for external inspection or additional process steps. Engineered for complex threaded profiles — including gothic, round, planetary, and whitworth — the Mikroturn delivers micron-accurate parts from the very first part.

About Danobat

Danobat is a global leader in designing and manufacturing advanced, precise, high-value-added and engineered-to-order manufacturing solutions.

The company encompasses three renowned brands: Danobat, Overbeck and Hembrug. With over seven decades of expertise, Danobat specializes in creating innovative equipment, including precision grinding machines, lathes, and robotic systems for machining. Overbeck, with a century of proven excellence, stands as a distinguished German manufacturer focused on high-precision internal grinding machines. Hembrug, the leader in ultra precision hard turning lathes and hybrid machines, brings its fine turning and grinding capabilities to the forefront.